Salting, stirring and cleaning device for stuffed toys

A technology for cleaning devices and plush toys, which is applied in mechanical cleaning, high-pressure cleaning, textiles and papermaking, etc. It can solve problems such as difficult handling of coarse salt, inability to control the uniform shaking of coarse salt, and inability to control the intensity of manual cleaning. The effect of high cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

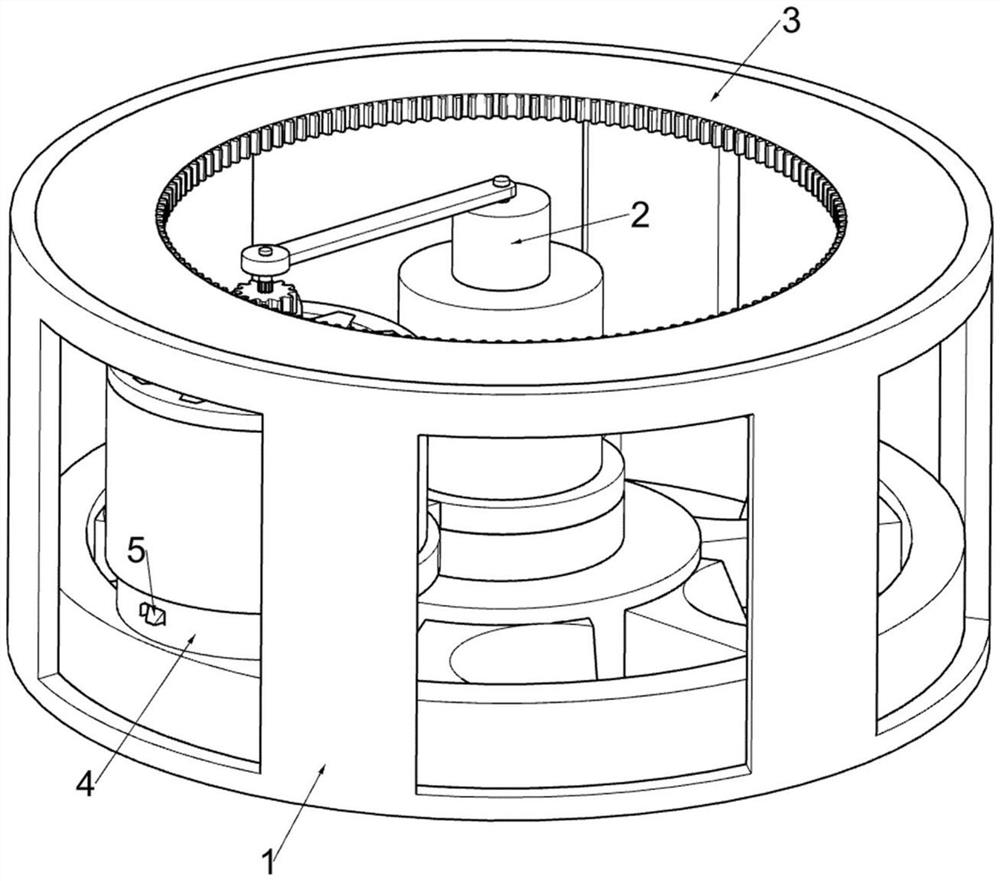

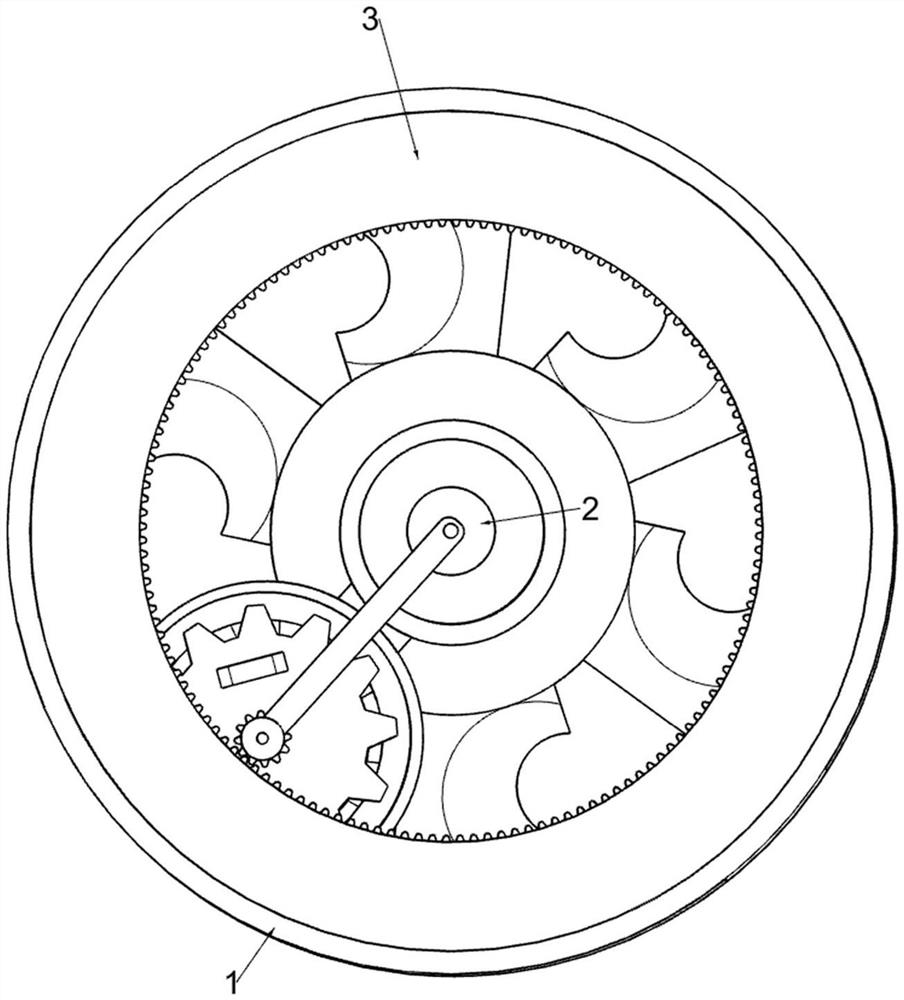

[0026] A plush toy adding salt, stirring and cleaning device, such as Figure 1-2 As shown, it includes a support frame 1, a rotating mechanism 2, a rotation stirring mechanism 3, a pushing mechanism 4 and a bottom opening and closing mechanism 5, the inner side of the support frame 1 is provided with a rotating mechanism 2, and the top of the support frame 1 is provided with a rotation stirring mechanism 3, The rotation stirring mechanism 3 is used for cleaning the plush toys. The rotation mechanism 2 is connected with the rotation stirring mechanism 3. A push mechanism 4 is provided on one side of the rotation mechanism 2, and the push mechanism 4 is used for cleaning the plush toys. The shaking falls on the chassis 4-5. The pushing mechanism 4 is provided with a bottom opening and closing mechanism 5, and the bottom opening and closing mechanism 5 is used to collect the coarse salt on the chassis 4-5 for centralized cleaning.

Embodiment 2

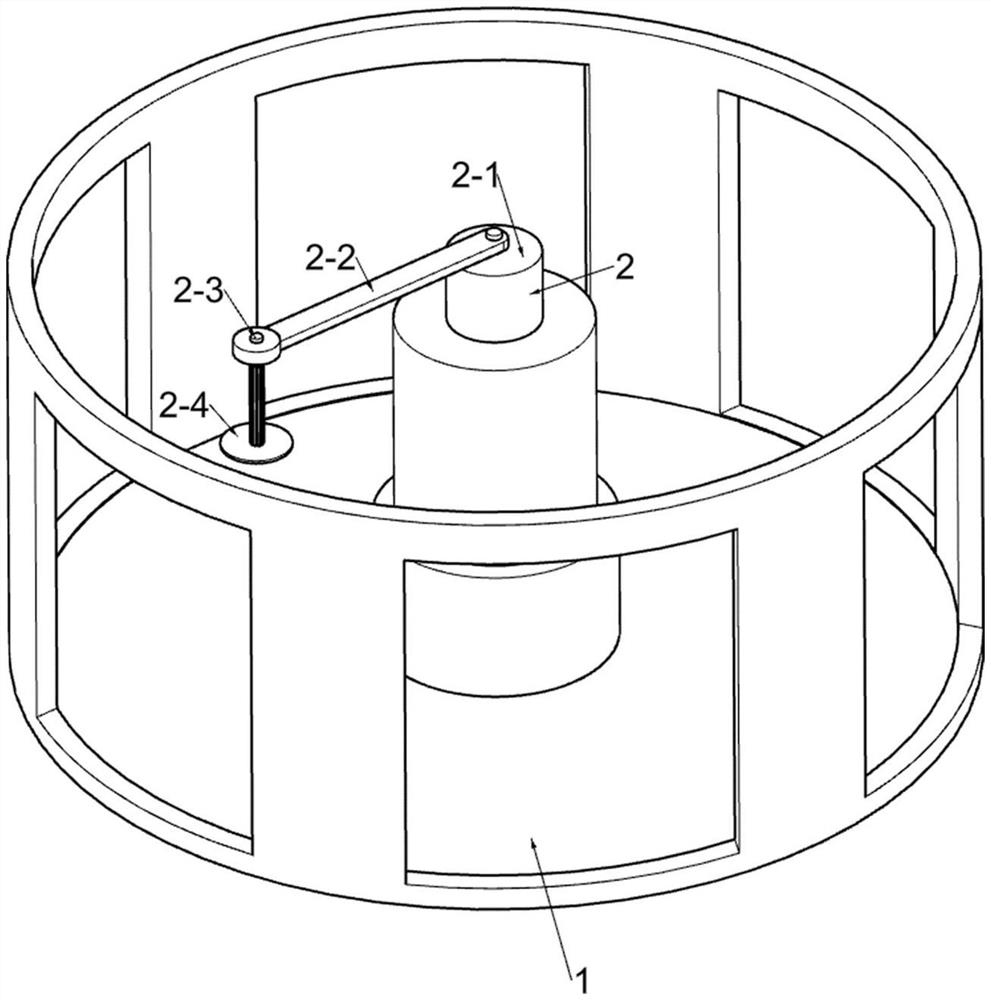

[0028] On the basis of Example 1, as Figure 1-8 As shown, the rotating mechanism 2 includes a motor 2-1, a connecting bar 2-2, a spline shaft 2-3 and a disc 2-4, the support frame 1 is fixedly connected with a motor 2-1, and the output shaft of the motor 2-1 is A connecting bar 2-2 is fixedly connected to the upper part, and the connecting bar 2-2 is located above the motor 2-1. One end of the connecting bar 2-2 is rotationally connected with a spline shaft 2-3 and a spline shaft 2-3 through a flat key. The lower end is welded with discs 2-4.

[0029] The rotation stirring mechanism 3 includes an inner gear 3-1, a toothed cover 3-3, a handle 3-4, a fixing frame 3-5 and a mixing drum 3-6, and an inner gear 3-1 is fixedly connected above the support frame 1 , the spline shaft 2-3 is fixedly connected with a spline hole gear 3-2 through a flat key, the spline hole gear 3-2 meshes with the inner gear 3-1, and the spline shaft 2-3 is slidably connected with a tooth The toothed c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com