Hybrid vehicle clutch control method and system

A hybrid vehicle, clutch control technology, applied in hybrid vehicles, motor vehicles, transportation and packaging, etc., can solve the problems of misidentifying clutch engagement and disengagement, increasing the cost of pressure sensors, and being unable to compensate for oil pressure hysteresis effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The hybrid vehicle clutch control method and system of the present invention will be further explained and illustrated in conjunction with the accompanying drawings and specific embodiments below. However, the explanation and illustration do not constitute an improper limitation on the technical solution of the present invention.

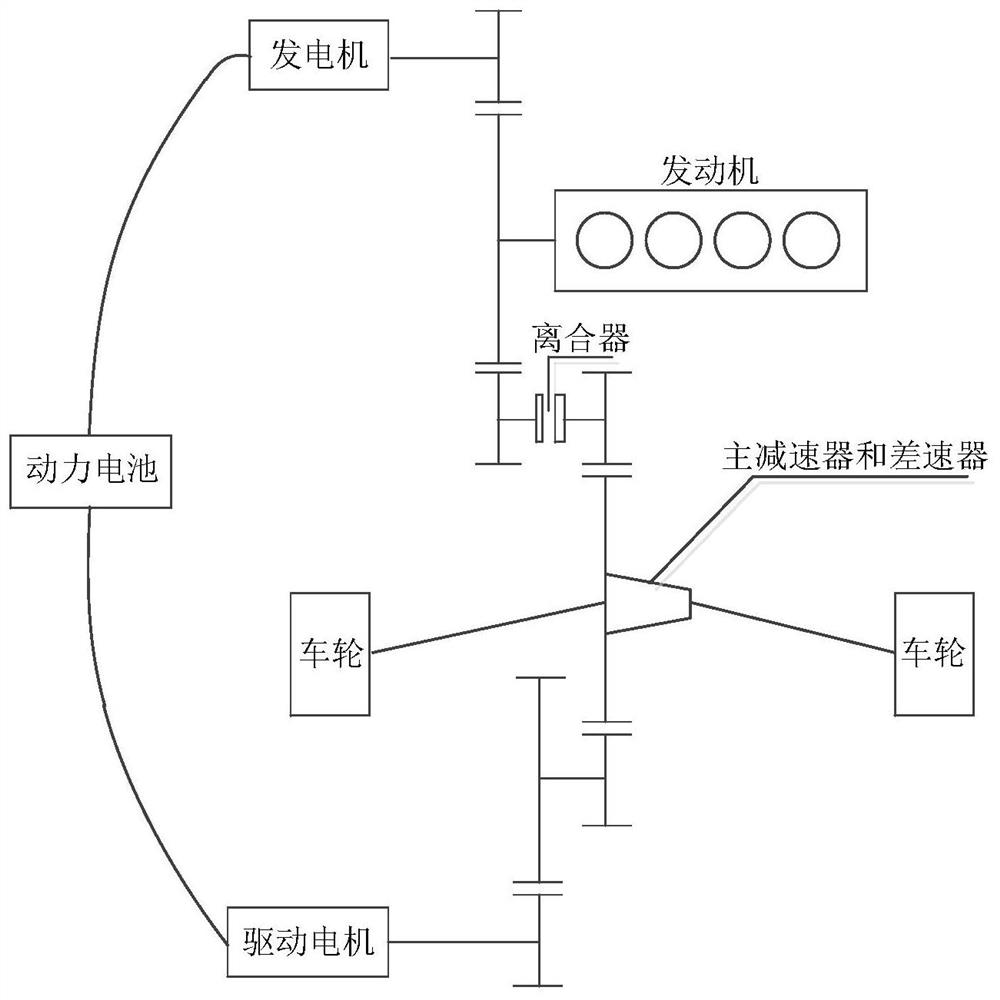

[0074] figure 1 A partial structure of a hybrid vehicle is schematically shown.

[0075] like figure 1 As shown, a hybrid vehicle may include: an engine, a generator, a drive motor and clutches, and several gear trains. In the present invention, the hybrid vehicle includes three drive modes: pure electric drive mode, series drive mode and parallel drive mode. Among them, the parallel drive mode means that the engine and the drive motor jointly provide power for the vehicle; the series drive mode means that the drive motor drives the wheels to rotate, and at the same time the engine drives the generator to charge the battery, and the battery...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com