Measuring and Controlling Method for Elongation and Bending of Carcass Cords of All-steel Radial Tire

A technology for radial tires and carcass cords, which is applied in the field of measurement and control of the elongation and curvature of the carcass cords of all-steel radial tires. and control methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

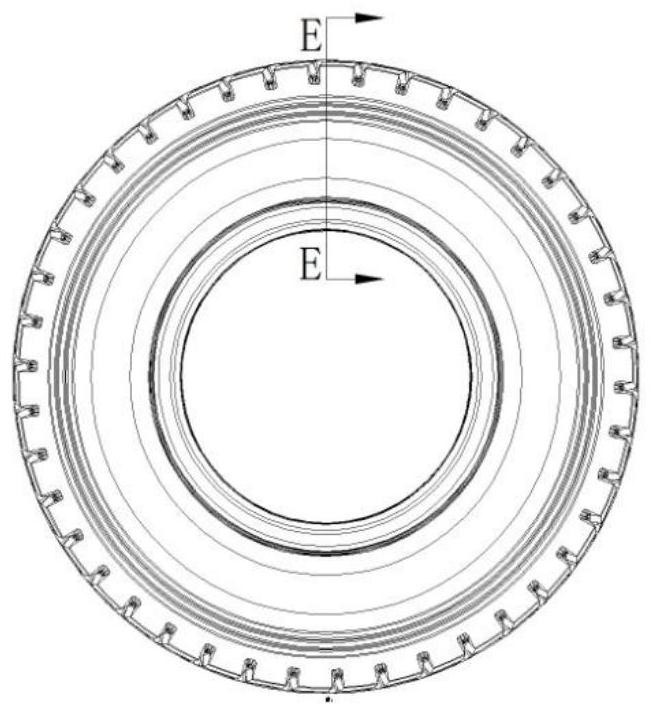

[0032] In order to make the technical solution of the present invention clearer and clearer to those skilled in the art, the following is combined with the appendix Figure 1-10 The technical solutions of the present invention are described in detail, but the embodiments of the present invention are not limited thereto.

[0033] The all-steel radial tire market has reported U-explosion and side-off problems, such as Figure 1-3 , Generally, the main carcass cord stretch is too large or too small.

[0034] The excessive extension of the cord includes three phenomena

[0035] 1. The cord bending is too straight, which may easily lead to exposed lines in the tire.

[0036] 2. If Figure 5 , Severe rubber leakage on the shoulder: Generally, the carcass cord is stretched too much, and it is easy to cause the transition layer rubber 2 in the shoulder inner liner to penetrate into the carcass cord, forming a glasses effect on the shoulder. If the stretch is serious, it may even ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com