Double-inerter parallel type four-order vibration reduction structure

A vibration-damping structure, parallel technology, applied in building components, protective buildings/shelters, earthquake-proof, etc., can solve the problems of excessively occupying the interior space of the engine room, the burden of the fan structure, and the large mass of the volume mass.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

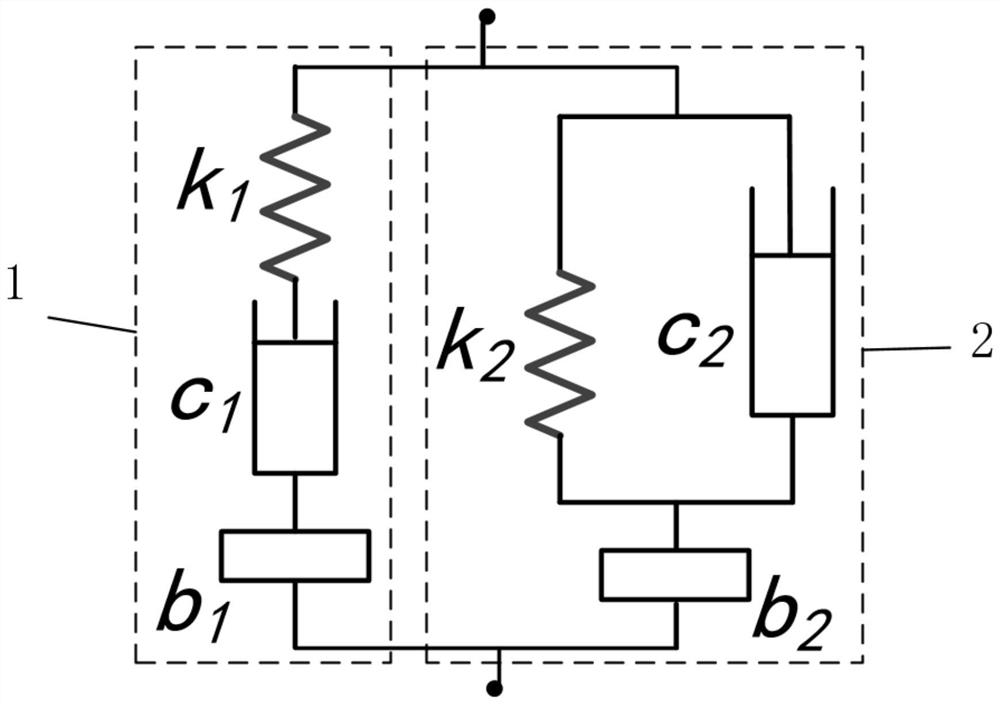

[0023] The first-stage, second-order damping structure 1 includes: a first-stage spring k1, a first-stage inertia b1, and a first-stage damping c1; and the spring k1, inertia b1, and The damping c1 is connected in series;

[0024] The second-stage, second-order damping structure 2 includes: a second-stage spring k2, a second-stage inertia b2, and a second-stage damping c2; and the spring k2 and damping c2 of the second-stage, second-order damping structure 2 After parallel connection, it is connected in series with inertial capacity b2.

Embodiment 2

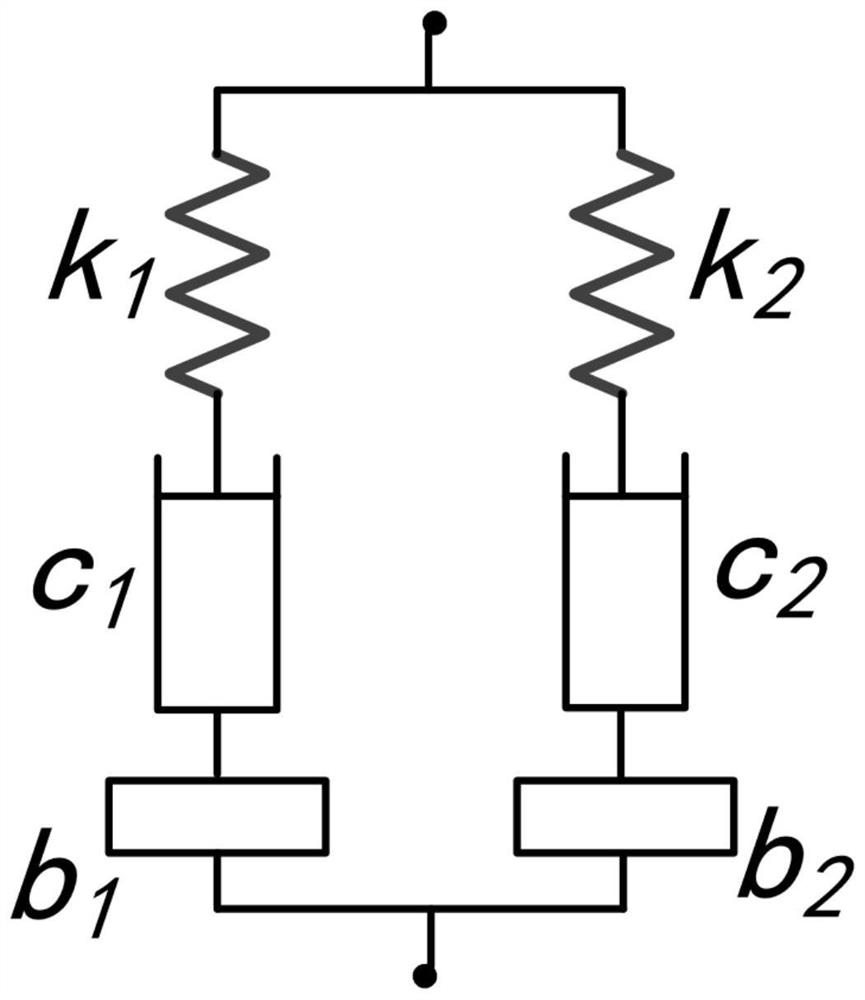

[0026] The first-stage, second-order damping structure 1 includes: a first-stage spring k1, a first-stage inertia b1, and a first-stage damping c1; and the spring k1, inertia b1, and The damping c1 is connected in series;

[0027] The second-stage, second-order damping structure 2 includes: a second-stage spring k2, a second-stage inertia b2, and a second-stage damping c2; and the spring k2, inertia b2 and damping c2 are connected in series.

Embodiment 3

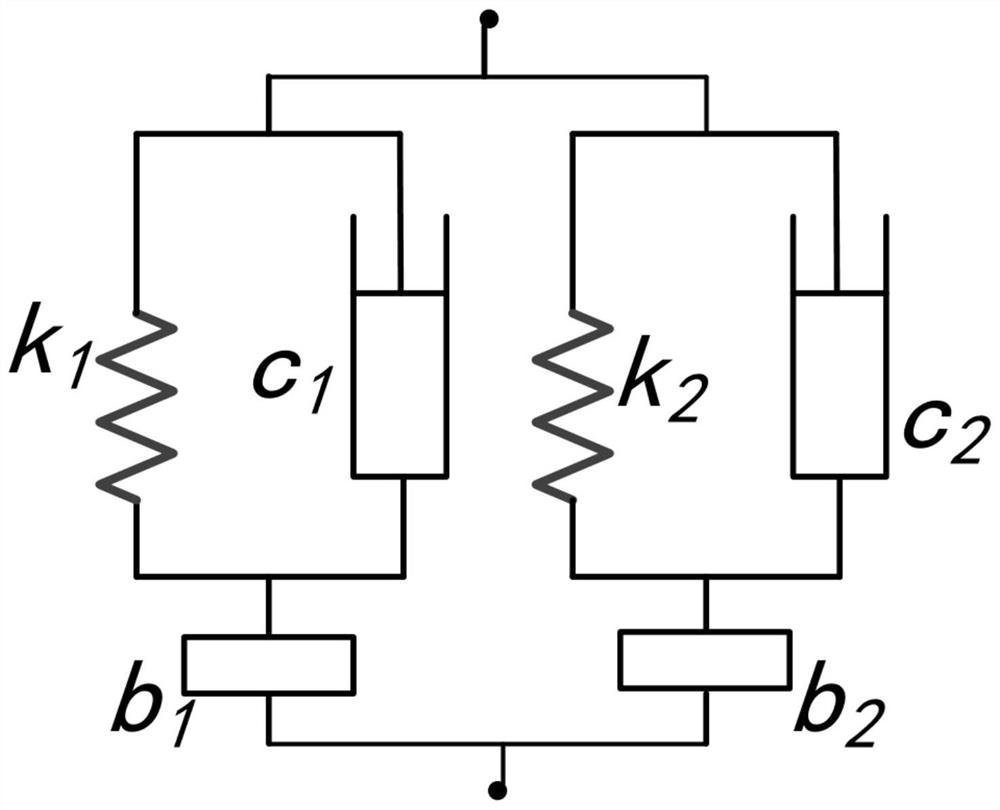

[0029] The first-stage second-order damping structure 1 includes: a first-stage spring k1, a first-stage inertia b1, and a first-stage damping c1; and the spring k1 of the first-stage second-order damping structure 1 is connected in parallel with the damping c1 Afterwards, it is connected in series with the inertial capacity b1;

[0030] The second-stage, second-order damping structure 2 includes: a second-stage spring k2, a second-stage inertia b2, and a second-stage damping c2; and the spring k2 and the damping c2 of the second-stage, second-order damping structure 2 are connected in parallel Afterwards, it is connected in series with the inertial capacity b2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com