Heating control method of electronic cigarette and electronic cigarette

A heating control and electronic cigarette technology, applied in the field of electronic cigarettes, can solve problems such as increasing the probability of damage to the atomizer and oil leakage, drying or burning of the heating wire, and increasing the temperature of the atomizer, so as to achieve stable smoke size, Prevent burning, adjust accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

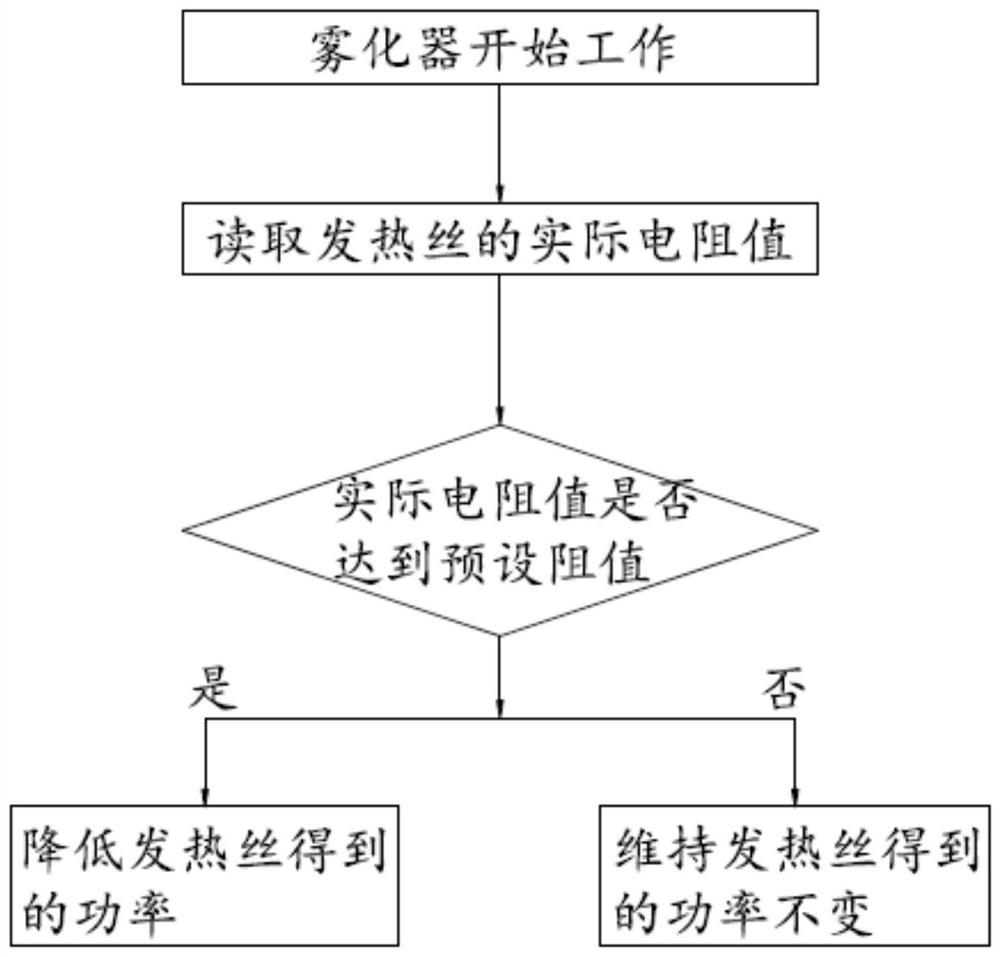

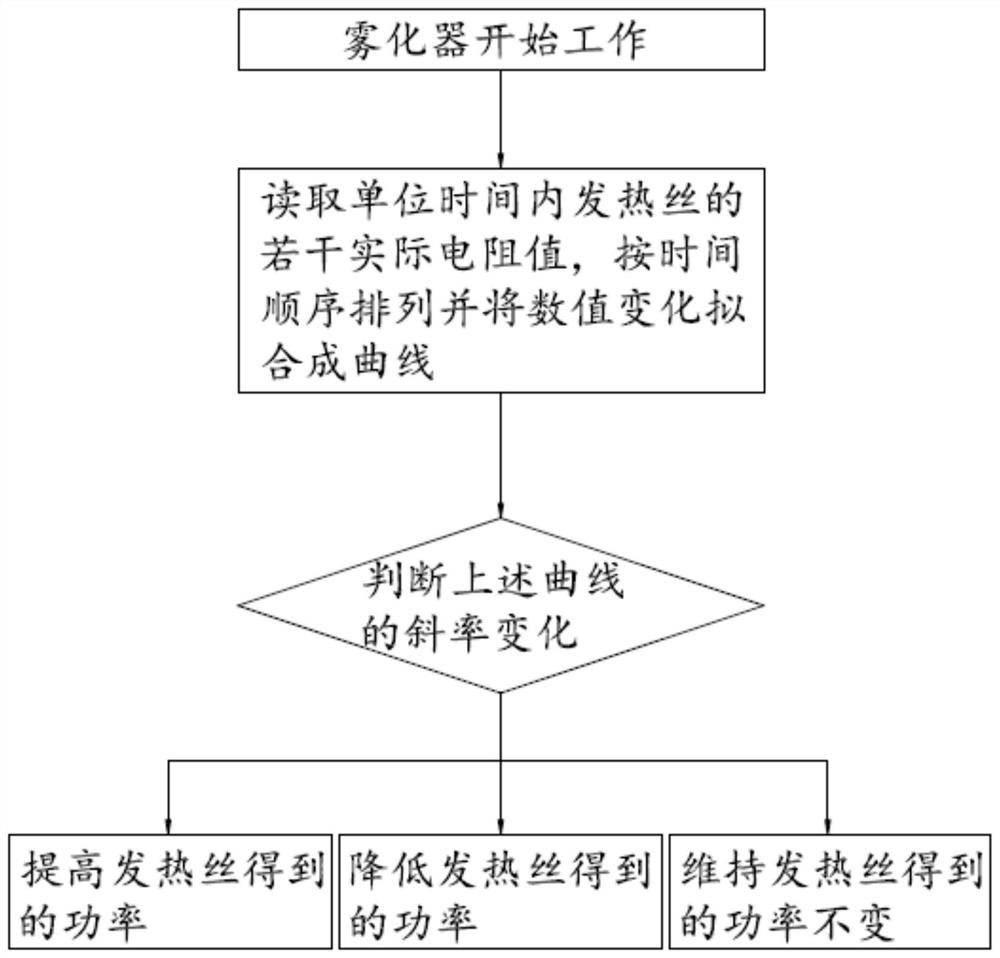

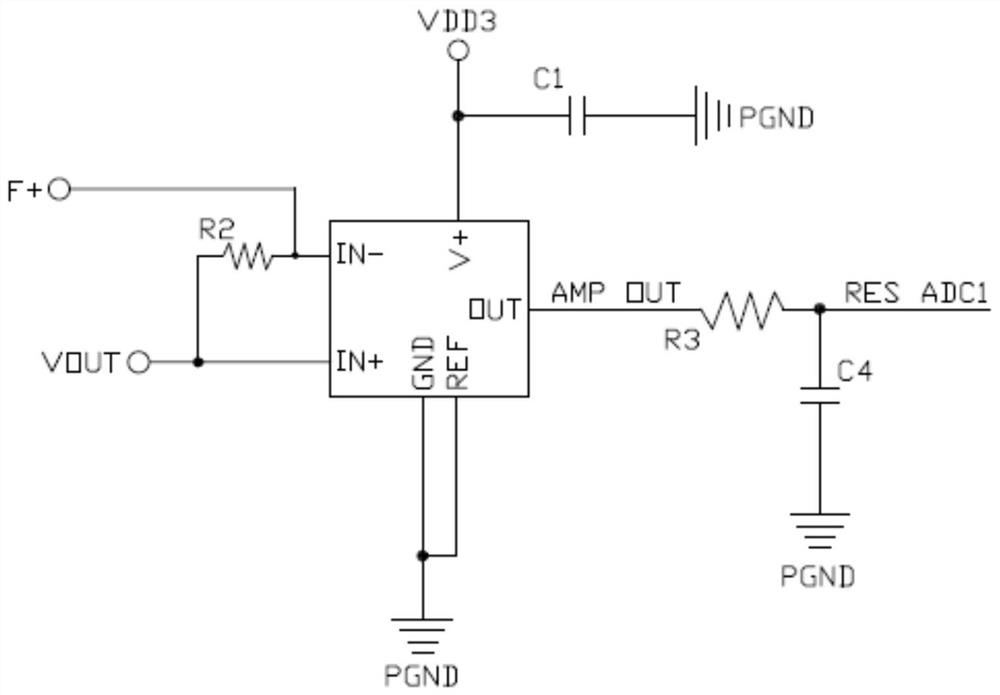

[0024] refer to Figure 1 to Figure 7 , the invention discloses a heating control method of an electronic cigarette and the electronic cigarette. The innovation point lies in the method of adjusting the power of the heating wire by detecting the resistance and optimizing the power adjustment at the same time.

[0025] The heating wire with temperature coefficient is selected to make the atomizer, and the resistance value of the heating wire increases with the increase of temperature. Obtain the normal temperature temperature value and normal temperature resistance value of the heating wire before the electronic cigarette is started. When obtaining the normal temperature resistance value of the heating wire, the current...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com