Running gear for a rail vehicle

A technology of running mechanism and rail vehicle, applied in the field of running mechanism for rail vehicle, can solve the problems of strong vibration transmission, short spring travel distance, etc., and achieve the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

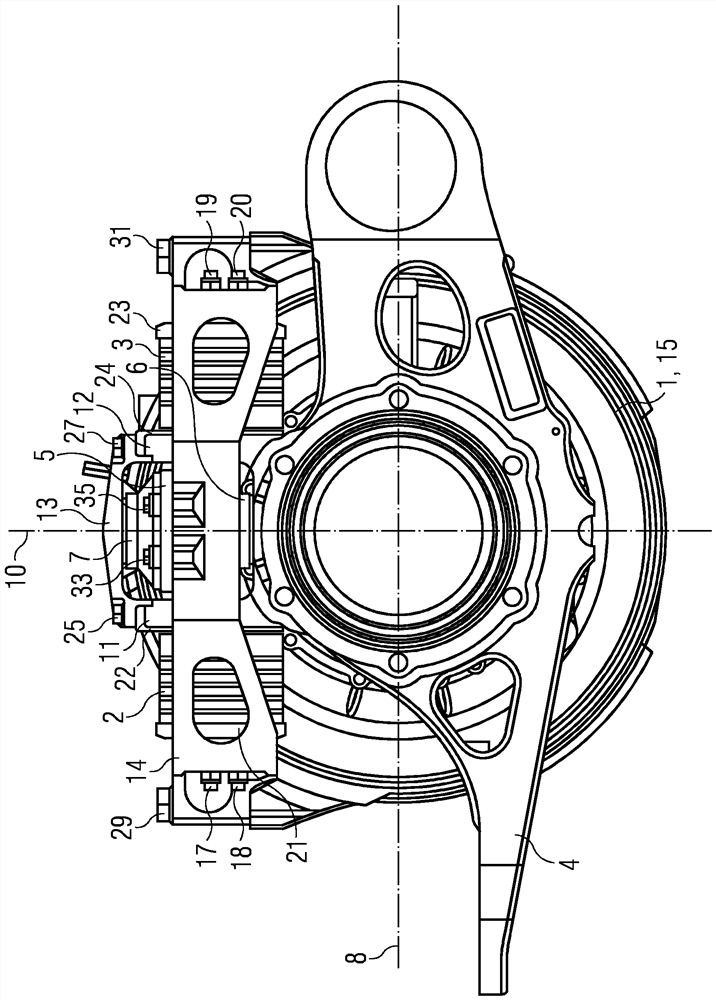

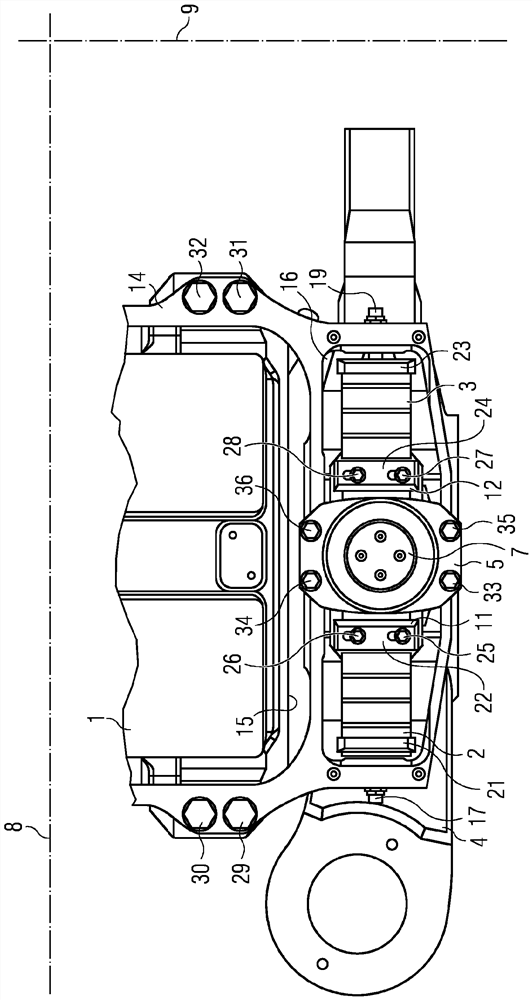

[0033] exist figure 1 The portion of the internally supported chassis of the rail vehicle shown in side view in FIG. 2 includes a chassis frame (not shown) to which a first wheel set and a second wheel set (also not shown) are coupled.

[0034] Set between the first wheel set and the running gear frame: a first wheel set support (not shown), which has a first wheel set support housing 4 or a first rocker arm and a first wheel set guide bushing ( Also not shown); and the second wheel set support, which has a second wheel set support housing or a second rocker arm and a second wheel set guide bushing, also not shown.

[0035] Arranged between the second wheel set and the chassis frame: a third wheel set bearing, which has a third wheel set bearing shell and a third wheel set guide bushing; and a fourth wheel set bearing, which has a fourth The wheel set supporting housing and the fourth wheel set guide bushing are also not shown.

[0036] Furthermore, a first main spring, not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com