Method for improving external critical heat flux density of pressure vessel

A critical heat flux density, pressure vessel technology, applied in reactors, greenhouse gas reduction, nuclear engineering, etc., can solve problems such as difficulty in making major design improvements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

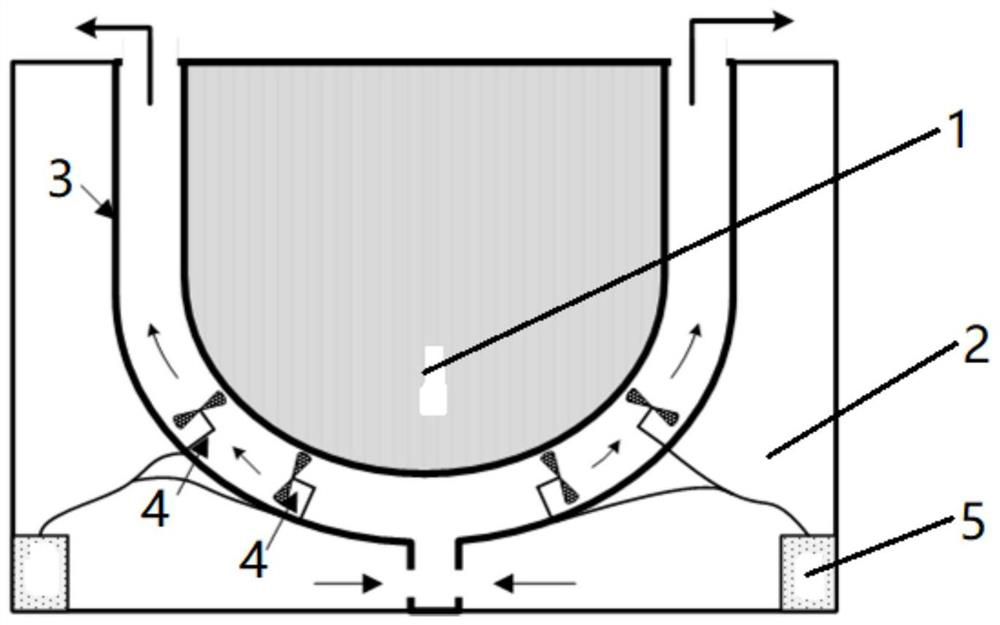

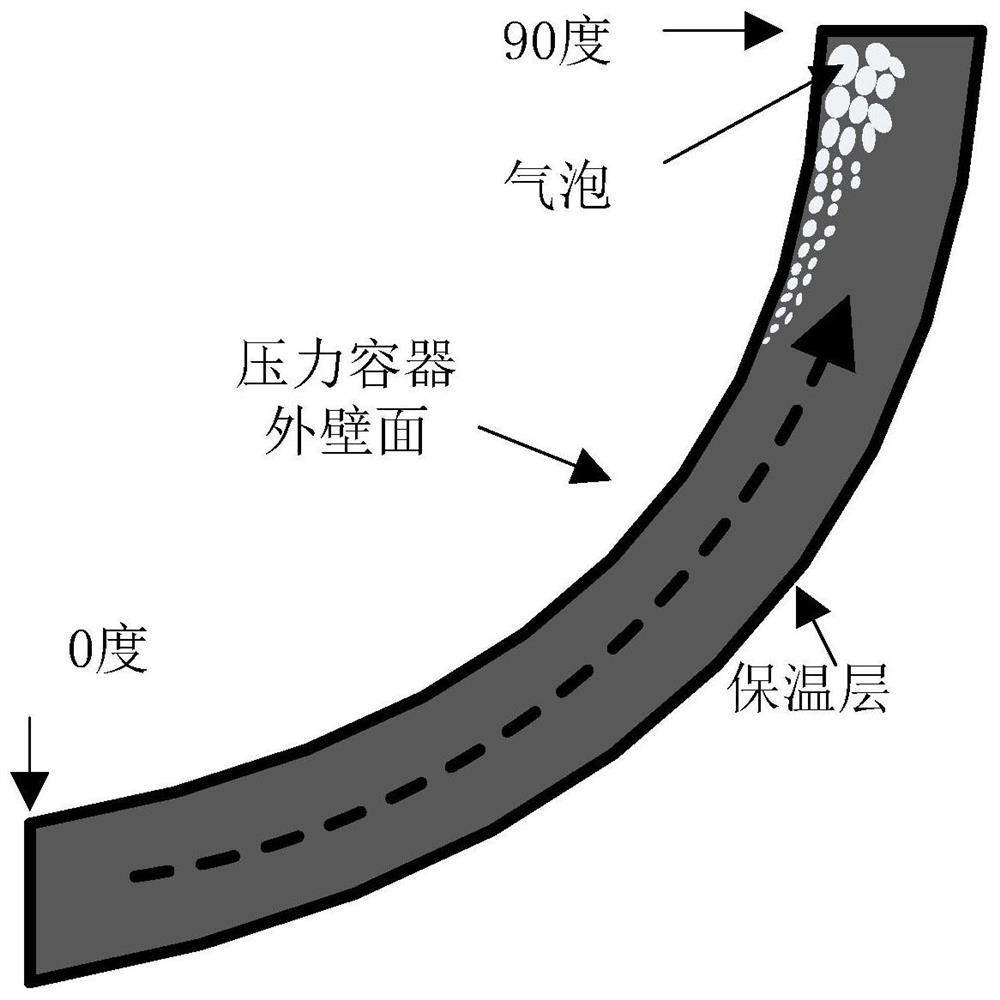

[0021] In the event of a severe accident in a nuclear power plant, if the exit temperature of the core exceeds a certain limit, the operator will be required to initiate the IVR strategy. The IVR strategy injects (by gravity or pumps) an external source of water into the reactor cavity. Among them, the water close to the wall of the pressure vessel will heat up to a boiling state, forming water vapor and leaving the reactor cavity. However, with the subsequent replenishment of water sources, such as water vapor condensed backflow, or the replenishment of small flow pumps, it can be stored in the reactor cavity compartment. Maintain a certain amount of water to form a natural cycle.

[0022] like Figure 1 to Figure 4 Shown, the method for improving the external critical heat flux of pressure vessel under the serious accident of nuclear power plant of the present invention, it comprises the steps:

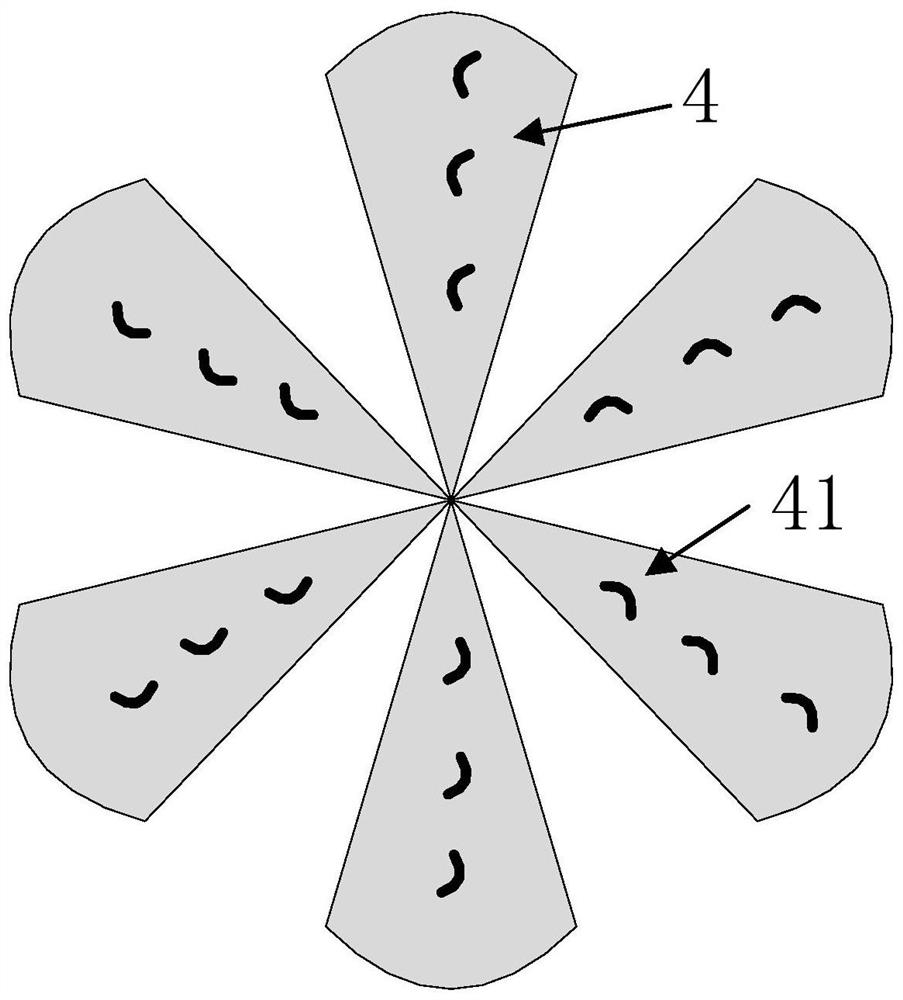

[0023] (1) A number of mixing rotors 4 are installed in the reactor cavity co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com