Profile finish machining method based on three-dimensional cam profile materialization model deviation compensation

A materialized, cam-type technology, applied in the field of parts finishing, can solve the problems of high processing cost, unstable cam surface quality, frequent batch problems, etc., and achieve the effect of ensuring the quality level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] A finishing method based on deviation compensation of a solid model of a three-dimensional cam profile, comprising the following steps:

[0028] 1) Process the sample according to the solid model of the three-dimensional cam surface;

[0029] Specifically, use the programming module of UG NX software to reasonably select the processing tool, driving geometry, cutting mode, etc., establish the CNC program based on the five-axis CNC machining center, and process the sample.

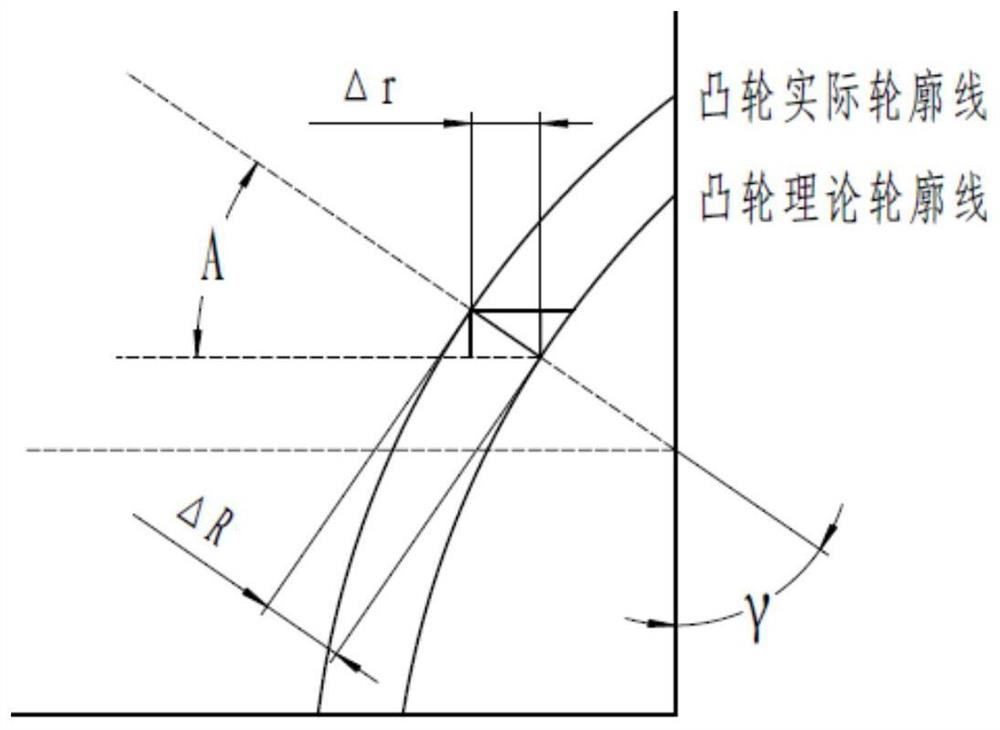

[0030] 2) On-line detection of the polar radius deviation Δr on the XY projection plane in the Cartesian coordinate system of multiple original detection qualified points and their corresponding processing points on the processed sample;

[0031] Using the Leitz three-coordinate measuring and testing equipment to online detect the coordinates of multiple original detection qualified points on the processed sample (x i0 、y i0 ,z i0 ) and the coordinates of the corresponding processing point (x i1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com