Modular sabot separation device and using method thereof

A separation device and modular technology, which is applied to launch devices, measurement devices, analytical materials, etc., can solve problems such as damage, hidden dangers to laboratory personnel and equipment safety, and incomplete separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further illustrated below in conjunction with the accompanying drawings and specific embodiments, and it should be understood that these embodiments are only for illustrating the present invention and are not intended to limit the scope of the present invention.

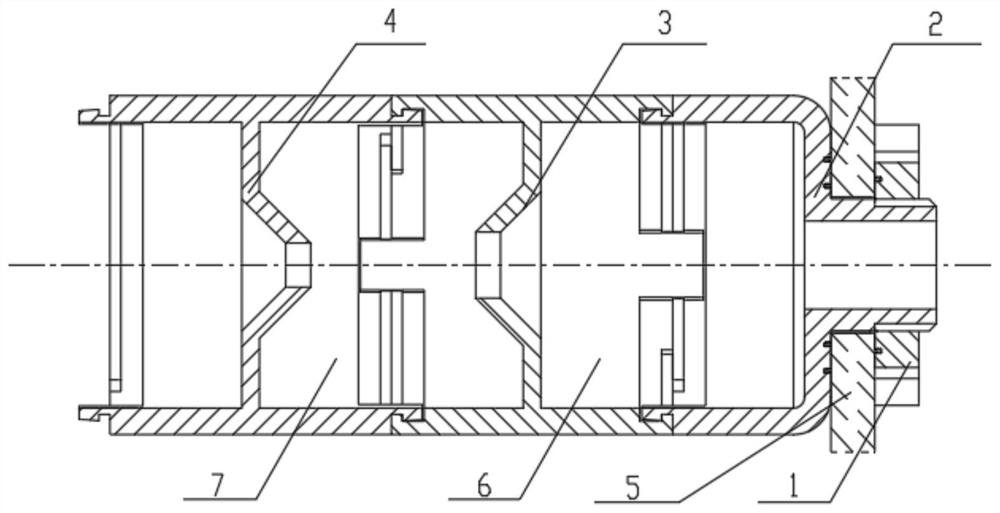

[0032] A modular spring stock separation device, such as Figure 1~6 As shown, it includes a fastener 1, a front retainer 2, a bomb holder separator 3, and a first-stage debris recovery device 4. Through the cavity, the fastener 1 is a fastening round nut.

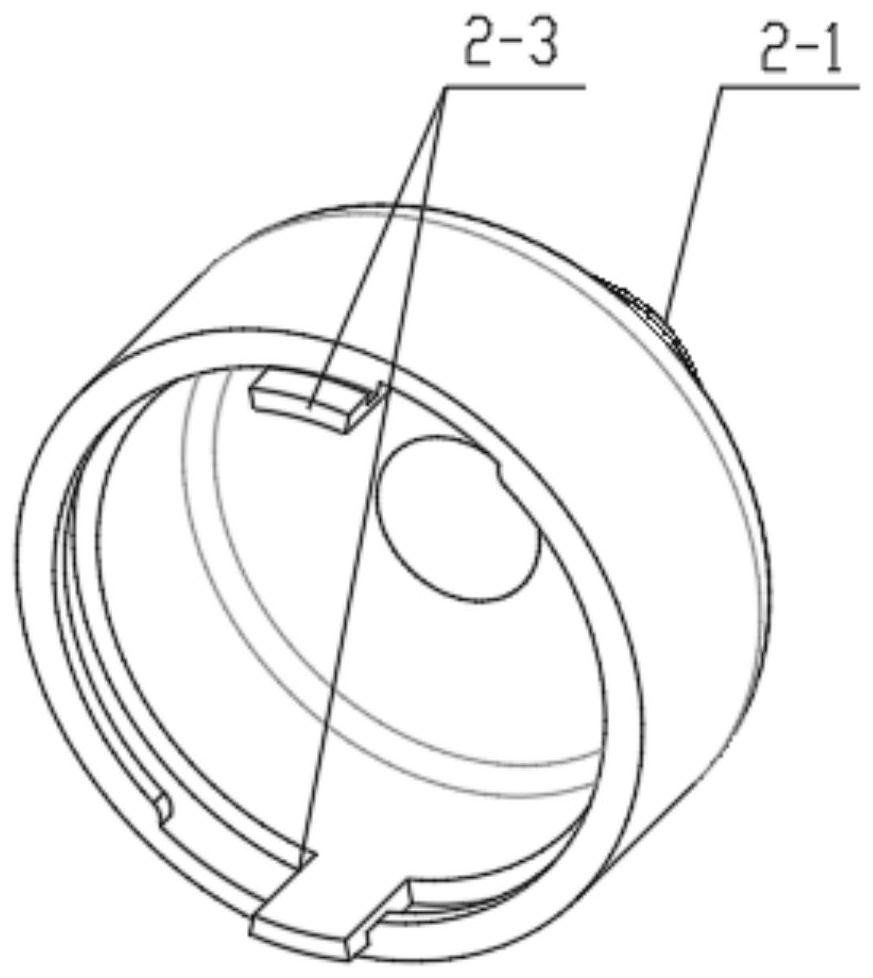

[0033] Anterior retainer 2 comprises retainer body 2-1, sealing ring 2-2, the first buckle joint 2-3, and the cross section of retainer body 2-1 is convex shape, and the diameter of its big end is twice of the diameter of small end. Double, the target chamber bulkhead 5 is connected with the outer peripheral surface of the small end of the holder body 2-1 through the fastener 1, the fastener 1 is threaded with the outer perip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com