Oil groove sealing structure

A sealing structure and oil groove technology, which is applied in the direction of engine seals, shafts and bearings, bearing components, etc., can solve the problems of poor sealing reliability, difficult adjustment of sealing gap between sealing teeth and rotating parts, unfavorable sealing performance, etc., and achieve long-lasting The effect of sealing, preventing loosening, and ensuring the reliability of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

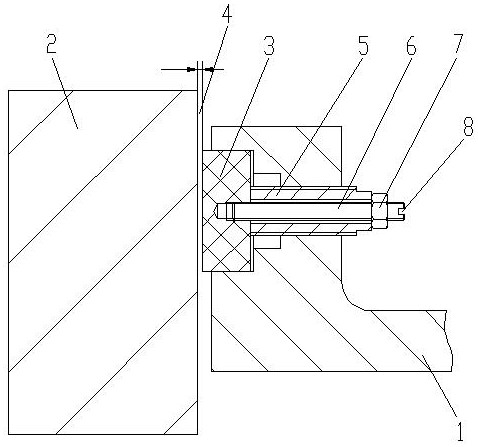

[0028] see figure 1 , an oil groove sealing structure, including a sealing cover 1 and a sealing tooth 3 adapted to a rotating part 2, a sealing gap 4 is formed between the sealing tooth 3 and the rotating part 2, and the sealing tooth 3 and the sealing cover 1 are in clearance fit, said The sealing cover 1 is provided with an adjustment member 5, the adjustment member 5 is connected with a screw 6, the screw 6 is covered with a nut 7, the end of the screw 6 is provided with a notch 8, and the sealing tooth 3 is connected with the adjustment Part 5 is tightly connected by screw rod 6 .

[0029] This embodiment is the most basic implementation. A sealing gap 4 is formed between the sealing tooth 3 and the rotating part 2. The sealing tooth 3 and the sealing cover 1 are in clearance fit. The sealing cover 1 is provided with an adjustment member 5, which penetrates Connected with a screw 6, the screw 6 is covered with a nut 7, the end of the screw 6 has a notch 8, the sealing to...

Embodiment 2

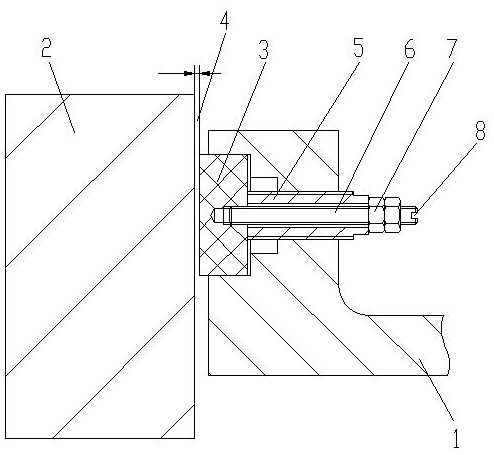

[0031] see figure 2 , an oil groove sealing structure, including a sealing cover 1 and a sealing tooth 3 adapted to a rotating part 2, a sealing gap 4 is formed between the sealing tooth 3 and the rotating part 2, and the sealing tooth 3 and the sealing cover 1 are in clearance fit, said The sealing cover 1 is provided with an adjustment member 5, the adjustment member 5 is connected with a screw 6, the screw 6 is covered with a nut 7, the end of the screw 6 is provided with a notch 8, and the sealing tooth 3 is connected with the adjustment Part 5 is tightly connected by screw rod 6 .

[0032] There are two nuts 7 , and the two nuts 7 are arranged side by side on the screw rod 6 .

[0033] This embodiment is a preferred implementation mode. There are two nuts 7, and the two nuts 7 are arranged side by side on the screw rod 6. By adopting the double nut 7 structure, the sealing teeth 3 and the adjustment member 5 can be firmly connected together to ensure Use reliability. ...

Embodiment 3

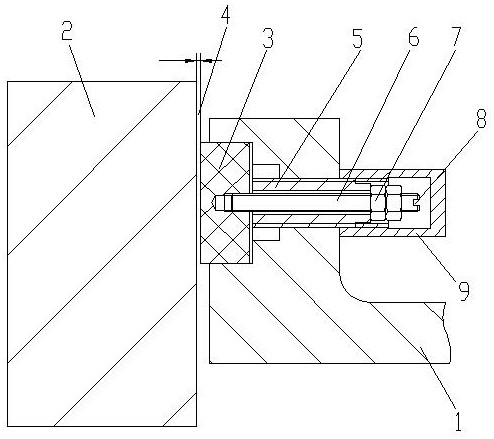

[0035] see image 3 , an oil groove sealing structure, including a sealing cover 1 and a sealing tooth 3 adapted to a rotating part 2, a sealing gap 4 is formed between the sealing tooth 3 and the rotating part 2, and the sealing tooth 3 and the sealing cover 1 are in clearance fit, said The sealing cover 1 is provided with an adjustment member 5, the adjustment member 5 is connected with a screw 6, the screw 6 is covered with a nut 7, the end of the screw 6 is provided with a notch 8, and the sealing tooth 3 is connected with the adjustment Part 5 is tightly connected by screw rod 6 .

[0036] There are two nuts 7 , and the two nuts 7 are arranged side by side on the screw rod 6 .

[0037] The adjusting member 5 is connected with a locking member 9 with an inverted “U” shape in cross section, the opening end of the locking member 9 is connected with the sealing cover 1 , and the nut 7 is located in the locking member 9 .

[0038] This embodiment is another preferred impleme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com