Waste incineration plant coupled sludge low-temperature drying treatment system

A waste incineration and disposal system technology, applied in dehydration/drying/concentrated sludge treatment, refrigeration and liquefaction, chemical instruments and methods, etc., can solve problems such as high energy consumption, overheating, and increased burden on the tail gas treatment system, and achieve improvement Safety, low temperature, and environmental friendliness in the factory area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

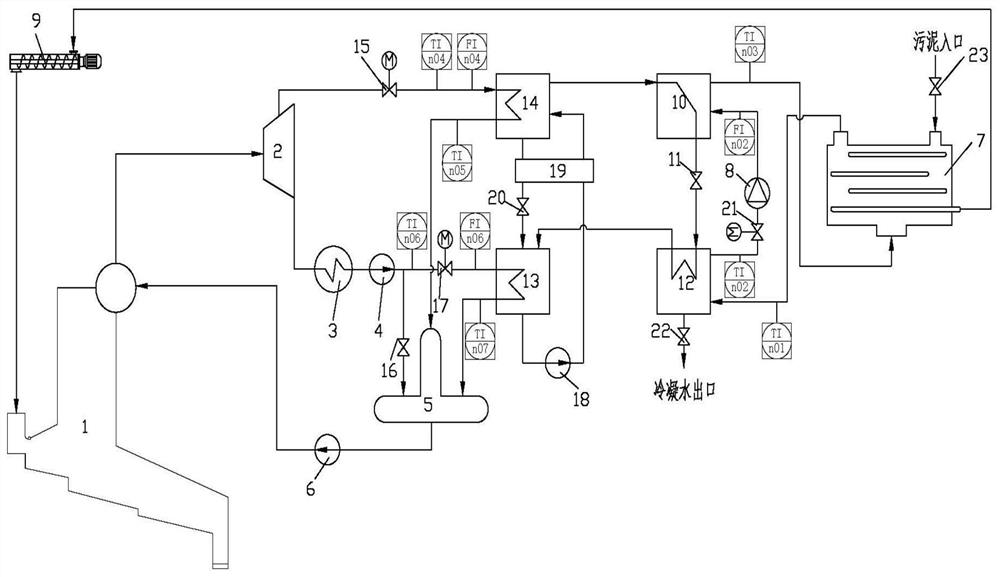

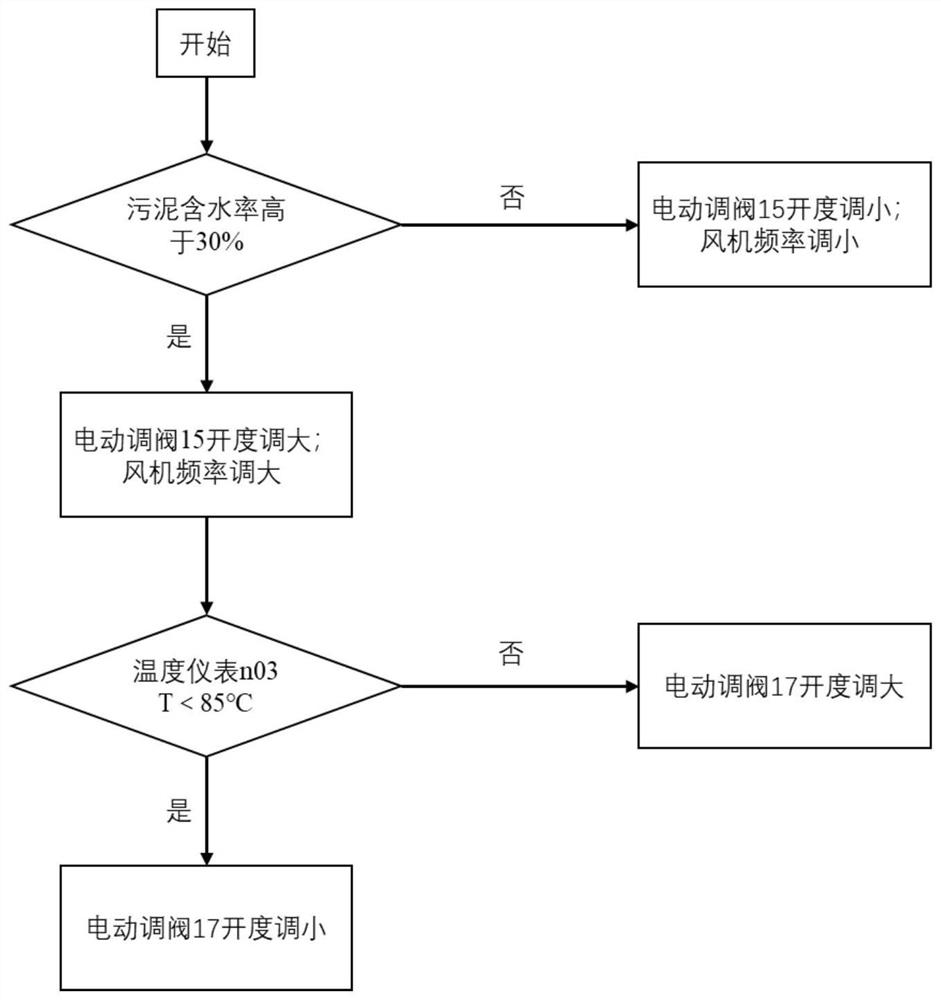

[0018] Such as figure 1 As shown, taking a 100t / d sludge drying project (drying sludge with a moisture content of 80% to 30%) as an example, the specific implementation of the present invention is further described. The steam generated by the waste incineration boiler 1 enters the steam turbine 2, and uses the low-pressure extraction steam (0.7Mpa, 255°C) of the steam turbine 2 as a high-temperature driving heat source to heat the generator 14. Enter the deaerator 5 for recycling. The steam generated by the generator 14 enters the condenser 10 as a power heat source for heating the dry air, and the condensed water entering the evaporator 12 after throttling is used to absorb low-grade heat energy in the humid air, and is bypassed from the condenser 3 through the circulating water pump 4 The feed water (0.8MPa) enters the absorber 13 to absorb heat and heat up, and the 27t / h bypass feed water is heated from 38°C to 75°C, and enters the deaerator 5 for recycling. 4. 17t / h of w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com