Lossless mirror surface grinding device for sheet for high-temperature rapid bonding of PE tape connector

A technology of ironing and grinding discs, which is applied to grinding drive devices, grinding heads, grinding machines, etc., can solve the problems of scrapping and replacing new sheets, increasing production costs, and inability to transmit stably and quickly at high temperature, and meets production requirements and has stable and consistent performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The principles and features of the present invention are described below, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

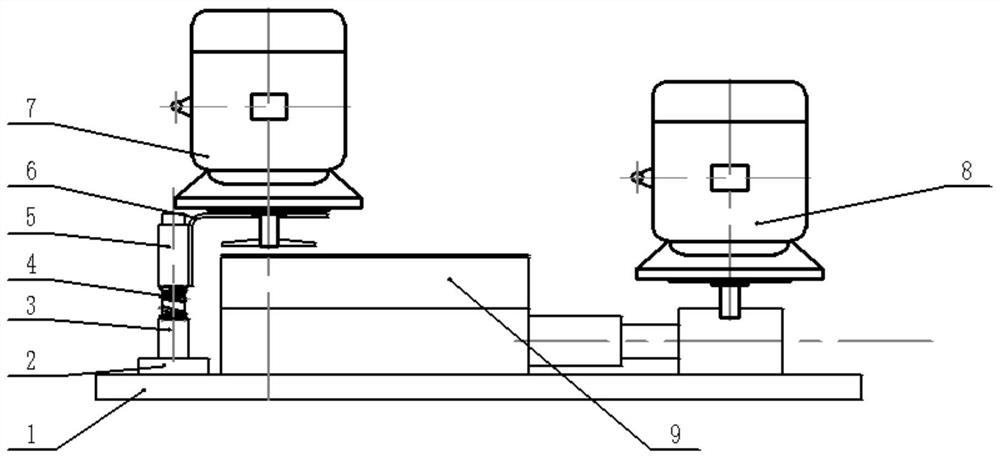

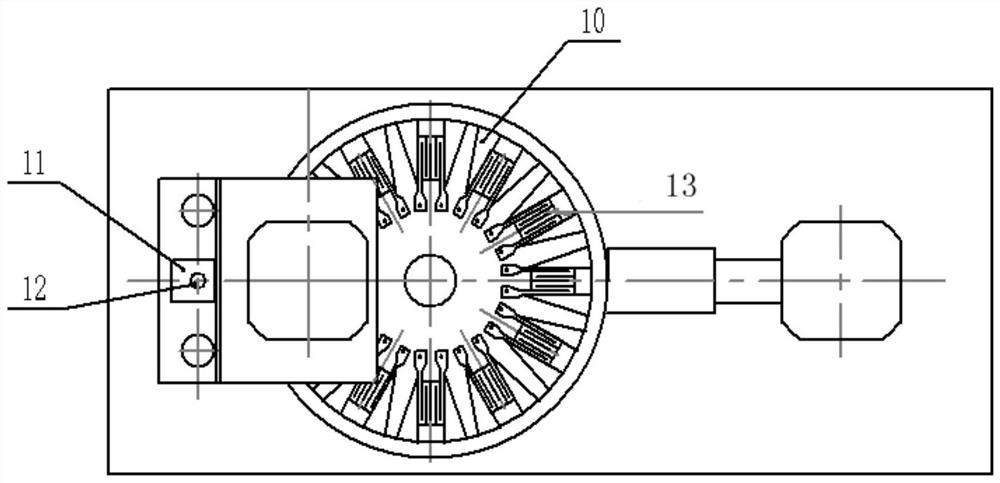

[0028] Such as figure 1 and figure 2 As shown, the present invention relates to a non-destructive mirror grinding device for ironing sheets, which includes a grinding disc 9 and a grinding head. The grinding disc 9 is in the shape of a disc arranged horizontally, and a plurality of clips for installing ironing sheets 13 are evenly distributed on it along the circumferential direction. groove 10, the grinding disc 9 can rotate axially around its vertical axis, the grinding head is located above the grinding disc 9, and can rotate axially around its vertical axis, and the grinding disc 9 and the The rotation direction of the grinding head is opposite, and the grinding head can move up and down and be positioned, and the grinding range of the grinding disc is wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com