Coal yard dust removal environmental protection equipment

A kind of environmental protection equipment and coal yard technology, applied in the direction of dust removal, separation of dispersed particles, chemical instruments and methods, etc., can solve the problems of different sizes of particles, easy secondary dust generation, and light-volume dust staying for a long time. To achieve the effect of enhancing air pressure penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

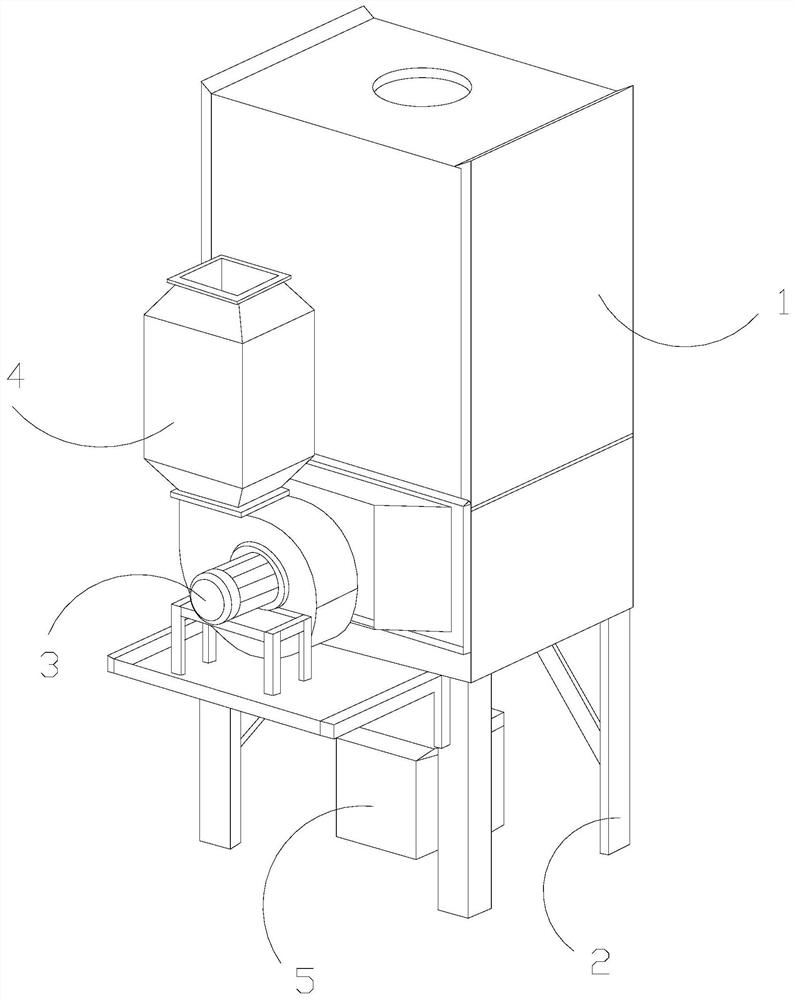

[0027] as attached figure 1 to attach Figure 6 Shown:

[0028] The present invention provides a kind of coal yard dedusting environmental protection equipment. The dust box 5 is connected through the bottom of the body 1 , the fan 3 is installed on one side of the body 1 , and the suction port 4 is connected above the fan 3 .

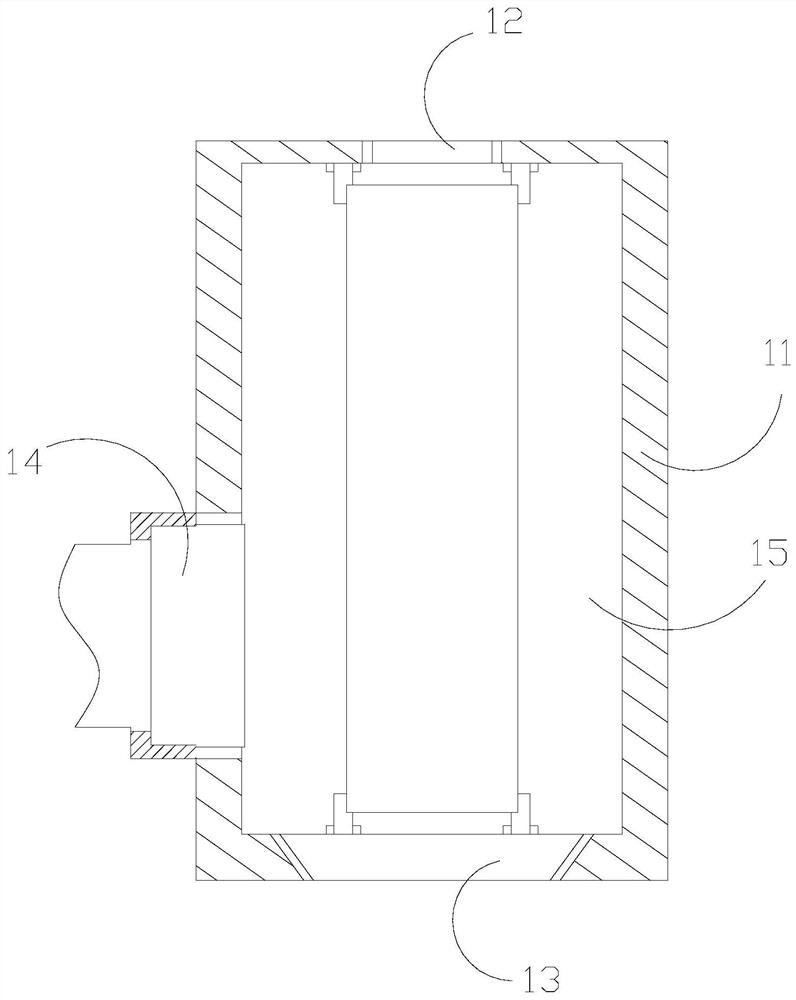

[0029] The body 1 is provided with a cylinder wall 11, an upper outlet 12, a lower outlet 13, a dust inlet 14, and a cylinder inner chamber 15. The cylinder wall 11 and the body 1 are an integrated structure, and the upper outlet 12 is located at The top position of the cylinder wall 11, the lower discharge port 13 is arranged at the bottom end of the cylinder wall 11, the upper discharge port 12 is located directly above the lower discharge port 13, and the dust inlet 14 is integrated with the cylinder wall 11 It is formed and penetrated at the lower position of its side end.

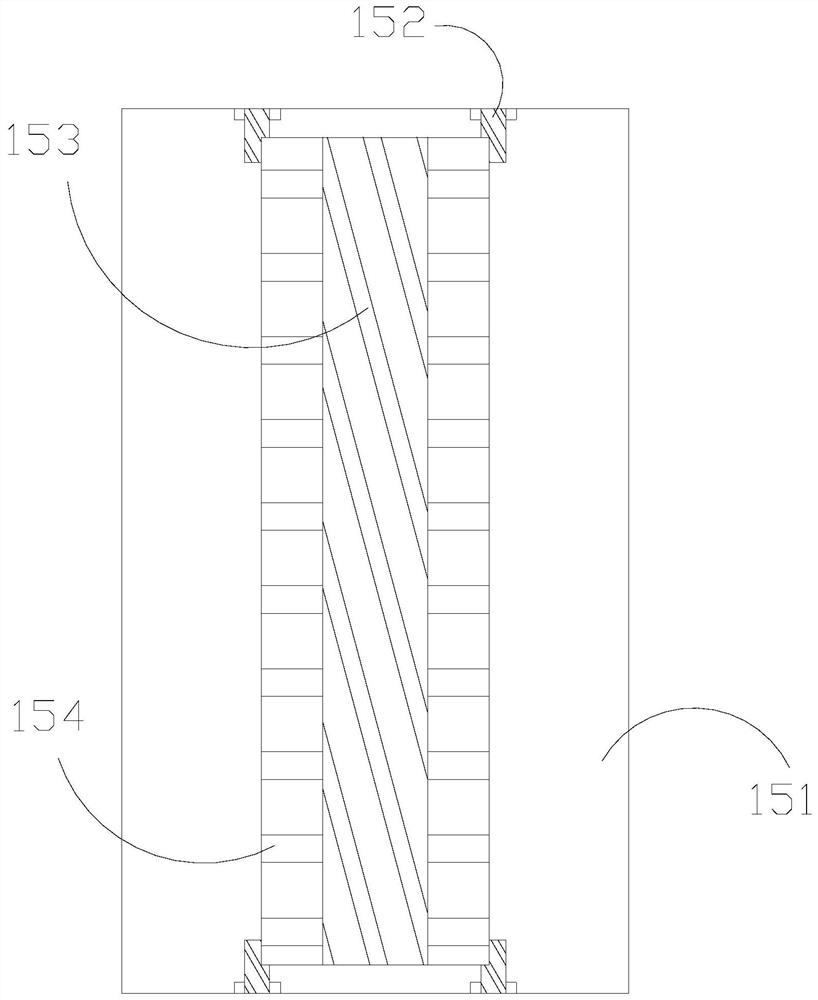

[0030] Wherein, the inner chamber 15 of the cylinder is provided with ...

Embodiment 2

[0036] as attached Figure 7 Shown:

[0037] Wherein, the swing door body w2 is provided with a through-hole side w21, a negative pressure bag w22, a mutual force bag w23, a support guide block w24, and a hard end w25, and the through-hole side w21 and the swing door body w2 are an integrated structure And it is set at the front end position, the negative pressure bag w22 is connected with the inner side of a21, the negative pressure bag w22 and the mutual force bag w23 are arranged in opposite directions and are movably matched, and the support guide block w24 is embedded and installed on the pendulum Inside the door body w2, the support guide block w24 is movably fitted between the negative pressure bag w22 and the mutual force bag w23, the hard end w25 is an integrated structure with the swing door body w2, and the through-hole side w21 is a At the front end of the port, the negative pressure capsule w22 and the mutual force capsule w23 are oval-shaped and made of rubber w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com