Magnetic connection structured assembly with self-protection function

A technology for connecting structures and connectors, applied in mechanical equipment, fixtures, etc., can solve the problems of consuming manpower, material resources, time and financial resources, increasing manufacturing costs and production costs, and increasing the labor intensity of operators, so as to achieve no potential safety hazards. , the effect of saving raw materials, strong scalability and compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

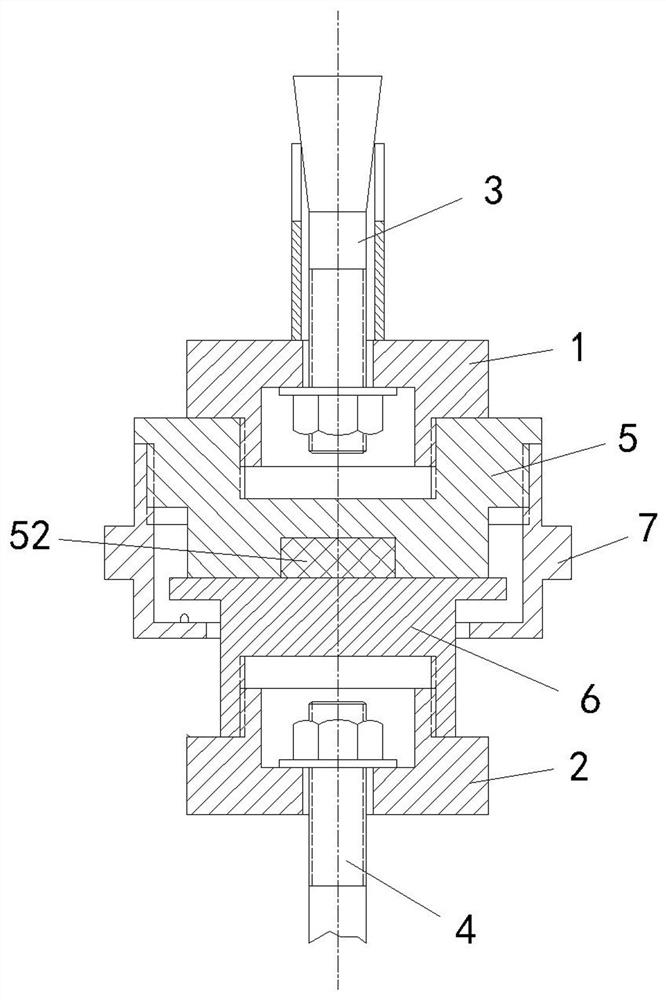

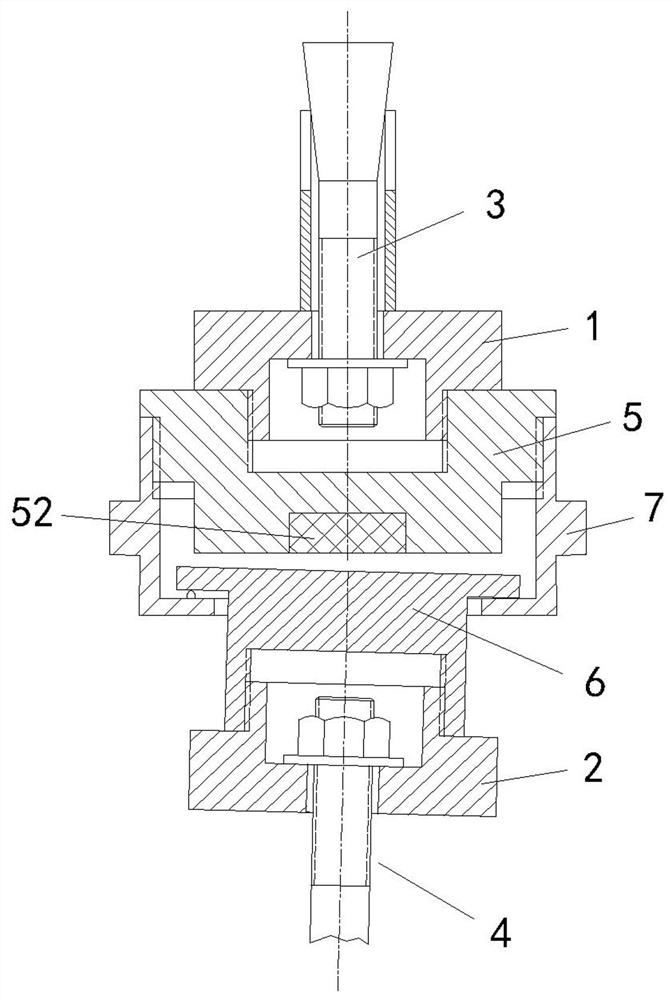

[0029] Such as figure 1 Shown: The self-protecting magnetically connected structured assembly of the present invention includes a first hole connector 1, a second hole connector 2, a third connector 5, a fourth connector 6, and a protective cover 7.

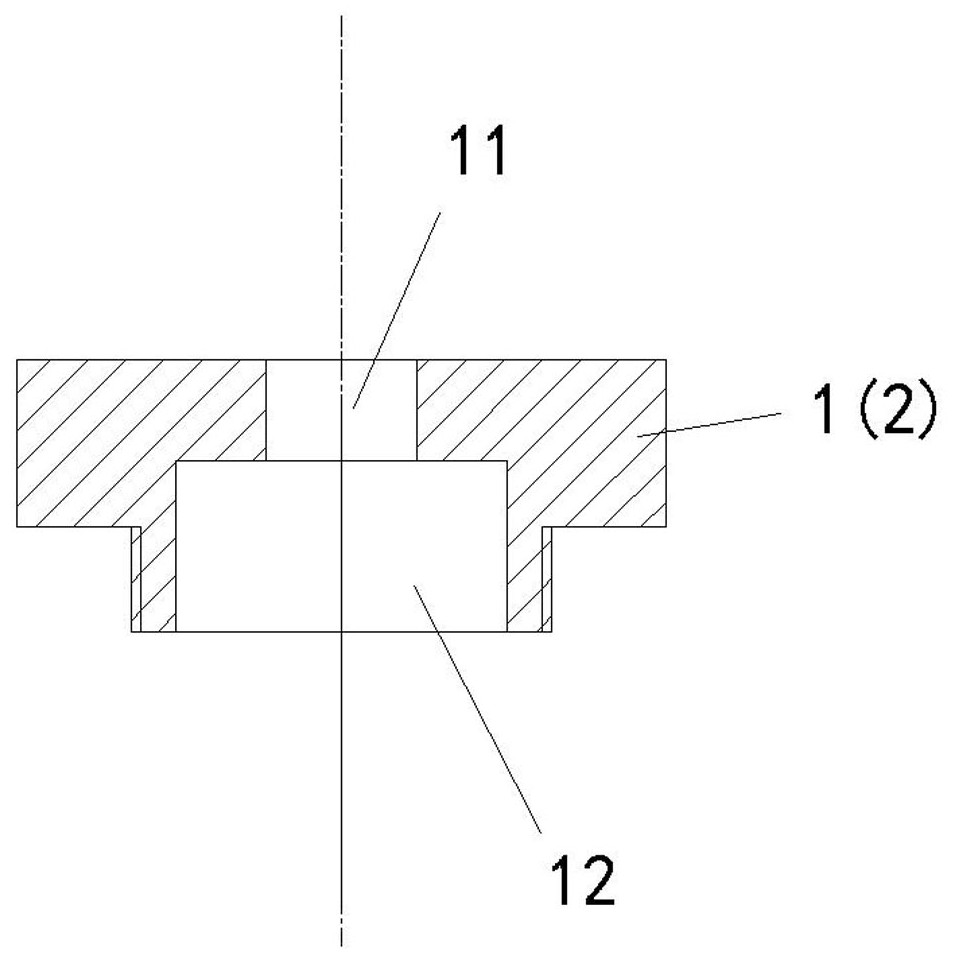

[0030] Such as image 3 As shown: one end of the first hole connector 1 has a first through hole 11 , and the other end has a first cavity 12 , and the first through hole 11 communicates with the first cavity 12 .

[0031] Such as Figure 4 As shown: one end of the second hole connector 2 has a second through hole 21 , and the other end has a second cavity 22 , and the second through hole 21 communicates with the second cavity 22 .

[0032] Such as Figure 5 As shown: the third connecting piece 5 is embedded with a magnetic block 52 , and the end has a third joint surface 51 .

[0033] Such as Image 6 As shown: the end of the fourth connecting member 6 has a fourth joint surface 61 and an edge 62 protruding outward.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com