Packaging box side edge plate turning mechanism and method

A flip mechanism and packaging box technology, applied in packaging, transportation and packaging, paper/cardboard containers, etc., can solve the problems of low folding efficiency and precision of the side panels of the packaging board, and improve the efficiency and convenience of feeding , Improve feeding efficiency and improve versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

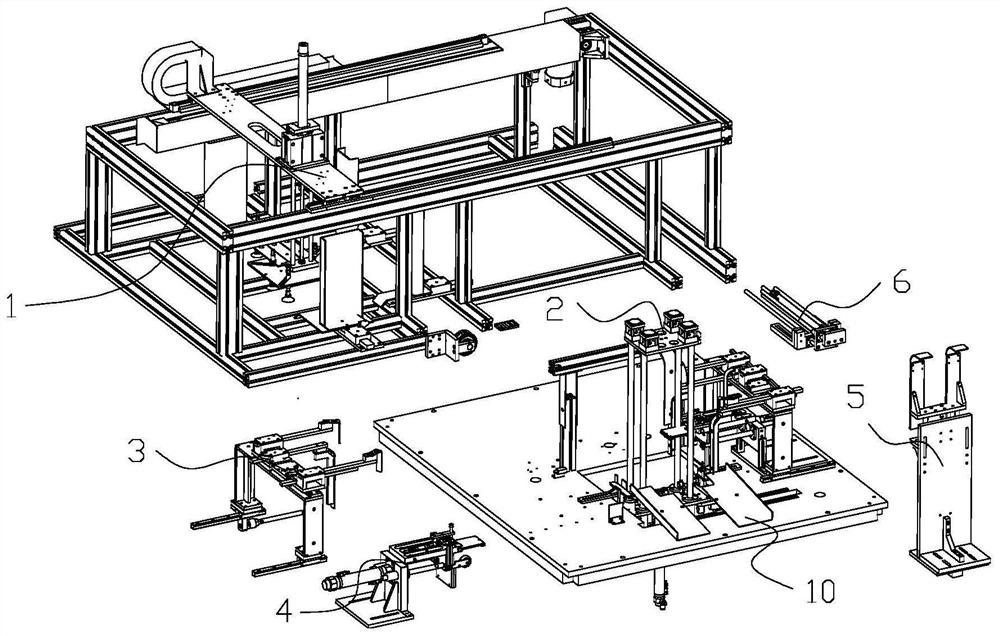

[0034] like figure 1As shown, an automatic packaging box forming equipment, the equipment includes a frame and a packaging board feeding device 1 on it, a packaging board lifting support device 2, a packaging board limiting device 3, and a first side flap positioning device 4 , the second side flap positioning device 5, the front flap device 6 and the blanking push-out device 7; the packaging board feeding device 1 is located above the frame; the packaging board feeding device 1 is used to place the horizontal packaging board Transported to the packaging board lifting support device 2; the packaging board lifting support device 2 is located in the center of the frame, and the packaging board lifting support device 2 is used to drive the packaging board for lifting and moving positioning; the packaging board limit device 3 is set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com