Automatic sofa seat frame production method

A production method and technology for framing, applied in the direction of wood processing utensils, manufacturing tools, etc., can solve the problems of cumbersome production steps, etc., and achieve the effects of good installation effect of the snake spring, ingenious design and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

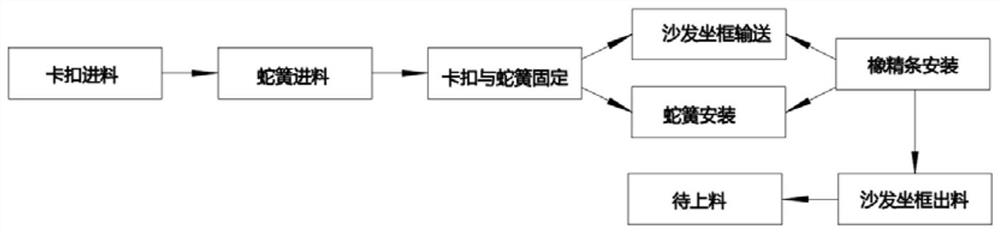

[0058] Such as figure 1 Shown, a kind of sofa seat frame automatic production method comprises the following steps:

[0059] Step 1: buckle feeding, the manipulator places the buckle opening inwardly on the moving block 121 and abuts against the baffle plate 32;

[0060] Step 2: Snake spring feeding. After step 1, the moving block 121 drives the rotating plate 122 to move directly below the snake spring feeding box 31. Under the action of the traverse assembly 21, the limit assembly 33 moves, so that A snake spring falls onto the rotating plate 122 and is limited by two sets of limit blocks 212;

[0061] Step 3: The buckle is fixed with the snake spring. After step 2, the rotating plate 122 leaves the feed box 31 of the snake spring. It is engaged with the buckle, and during the lateral movement of the snake spring, the adjustment assembly 23 drives the opening of the buckle outward, and then the pressing component 24 rotates to press the buckle so that the buckle and the sn...

Embodiment 2

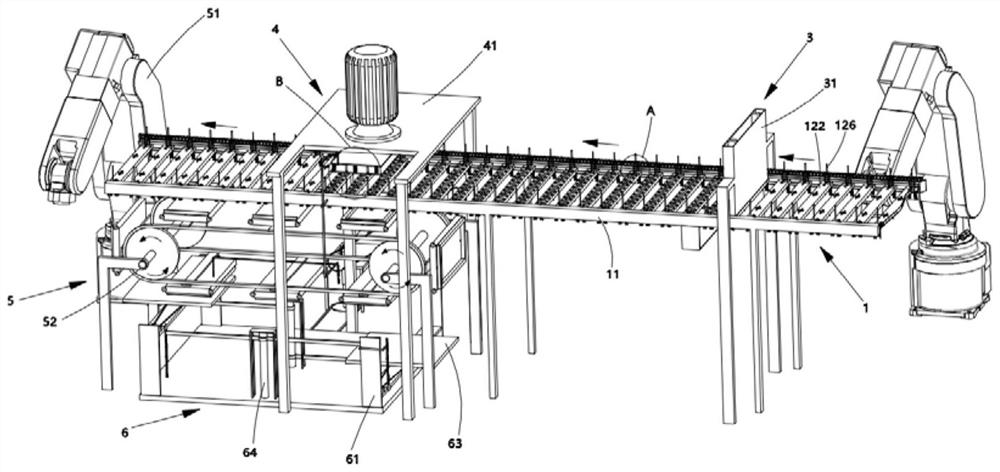

[0077] The present invention also provides a sofa seat frame automatic production system:

[0078] Such as figure 2 As shown, a sofa seat frame automatic production system includes:

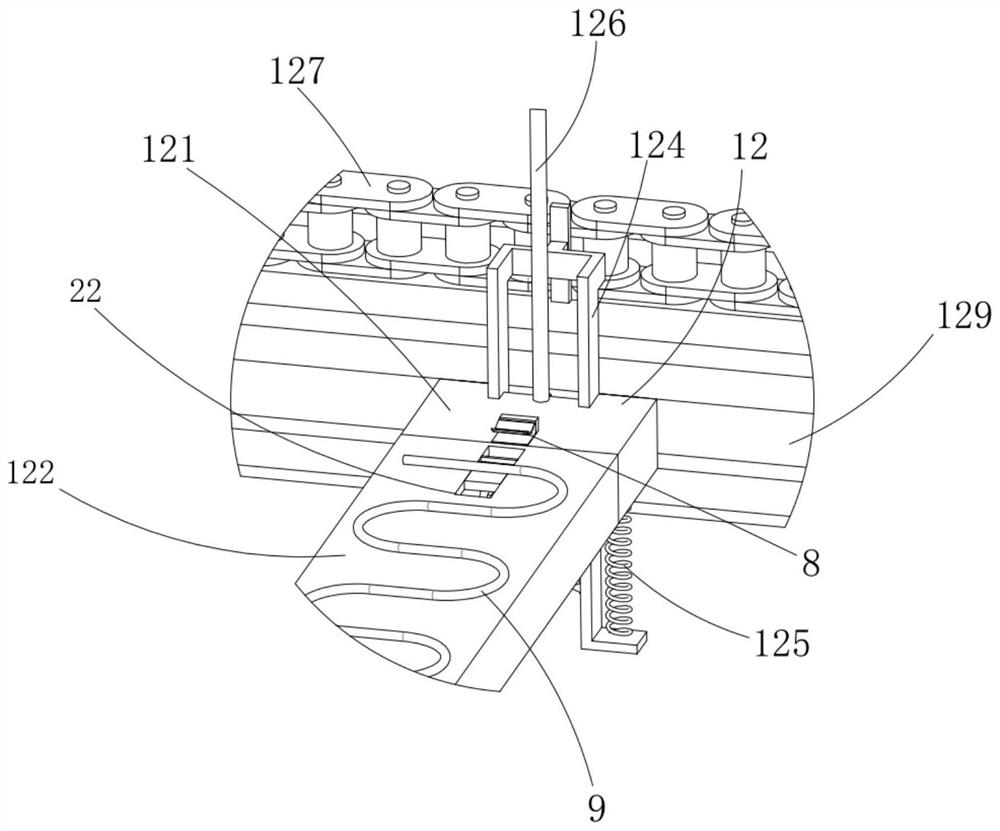

[0079] The transportation device 1, the transportation device 1 includes a mounting frame 11 and a moving assembly 12, the mounting frame 11 is arranged in a rotary manner; several groups of the moving assembly 12 move along the path of the mounting frame 11, and the moving assembly 12 includes symmetrically arranged and Two sets of moving blocks 121 that can be slid up and down and a rotating plate 122 that is rotatably installed between the two sets of moving blocks 121;

[0080] Fixing device 2, the fixing device 2 includes a lateral movement assembly 21 slidingly arranged on the rotating plate 122 left and right, two groups of square holes 22 opened symmetrically along the length direction of the rotating plate 122 and used for placing iron pieces, rotating The adjustment assembly 23 insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com