Device and method for enabling rotor to penetrate into exhaust end

A technology of exhaust end and exhaust end seat, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of difficulty in ensuring that the rotor does not collide with the bearing bush, affecting the operation effect of the compressor, and low hardness of the coating , to ensure the final operation efficiency, eliminate deviation and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

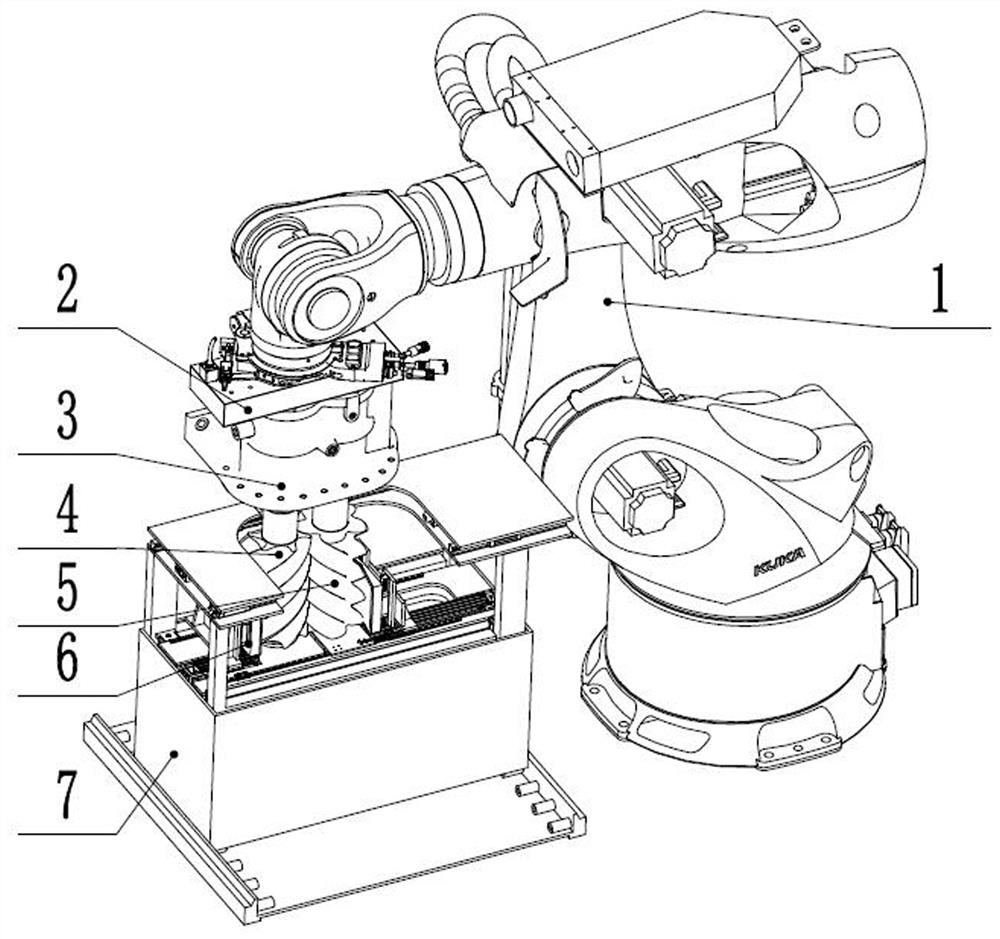

[0030] Such as figure 1 , a device for the rotor to penetrate the exhaust end, including a manipulator 1 and a grasping mechanism 2 installed at the end of the manipulator 1 , the grasping mechanism 2 is used to grasp the exhaust end seat 3 .

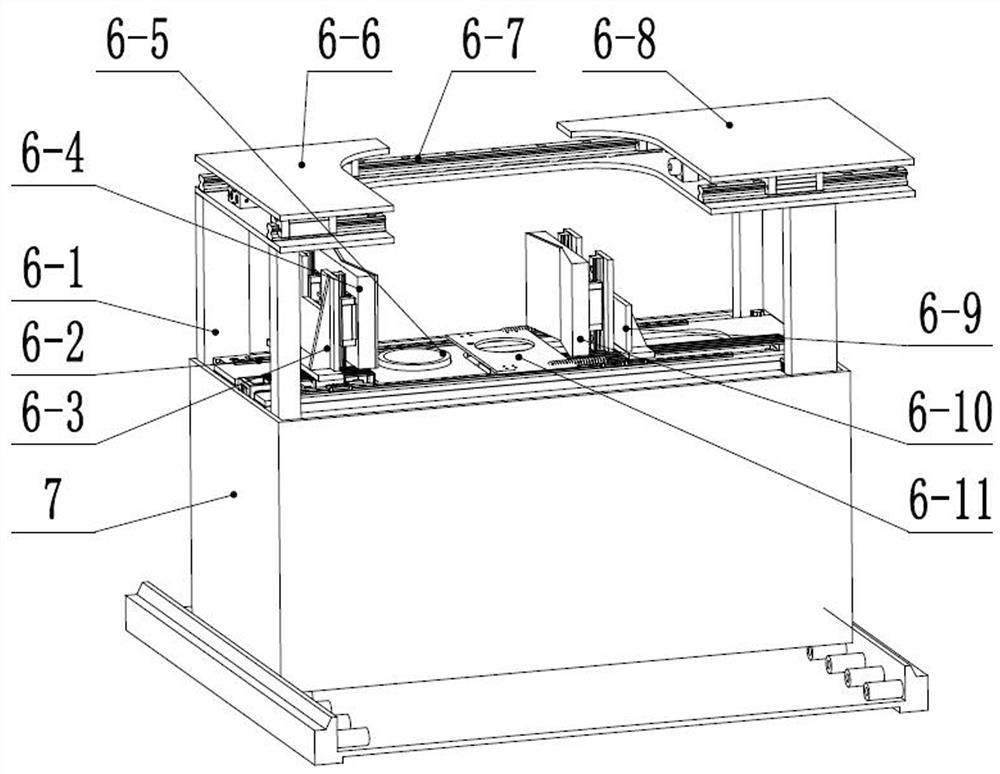

[0031] The device for the rotor to penetrate the exhaust end also includes a suspension workbench 7 and an engaging drive mechanism 6 .

[0032] The suspended workbench 7 includes a base on which several ball assemblies are placed and a platform is placed on the ball assemblies. When the ball assembly rises under the action of the cylinder to jack up the platform, the platform can move arbitrarily in the horizontal direction relative to the base. When the ball assembly descends and leaves the platform, the platform cannot move arbitrarily.

[0033] The meshing drive mechanism 6 is placed on a platform; the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com