Rock porosity measuring method and device

A technology of rock porosity and measurement method, applied in measurement devices, analysis of suspensions and porous materials, instruments, etc., can solve the problems of low precision and complex measurement algorithm, and achieve the effect of high precision, accurate measurement and elimination of errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings

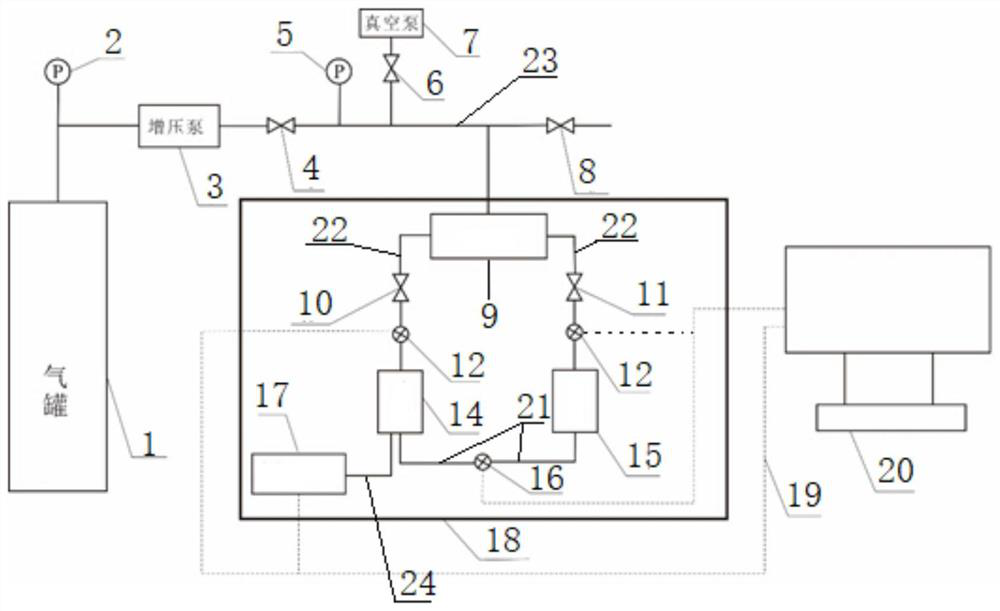

[0029] Such as figure 1 is a structural schematic diagram of rock porosity measurement, from figure 1 It can be seen that the gas increasing device is included: gas cylinder 1, pressure gauge 1 2, booster pump 3, valve 1 4 and pressure gauge 2 5, valve 2 6, vacuum pump 7, release valve 8, thermostat 18, temperature and pressure sensor 12, Differential pressure sensor 16, pulse flow metering device 17, industrial computer 20, pipeline one 21, pipeline two 22, pipeline three 23, pipeline four 24, reference pressure vessel 9, comparison pressure vessel 14, sample pressure vessel 15 , the reference pressure vessel 9, the comparison pressure vessel 14, and the sample pressure vessel 15 are arranged in the thermostat 18, and the reference pressure vessel 9 is respectively connected to the comparison pressure vessel 14 and the sample pressure vessel 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com