Dry and wet garbage separation sanitation box

A sanitation box and garbage technology, applied in the field of sanitation boxes, can solve problems such as lack of storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

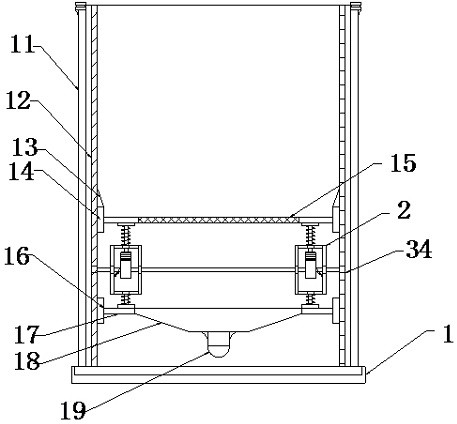

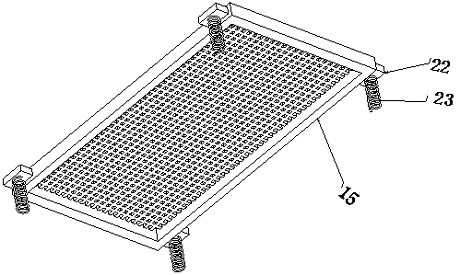

[0024] see Figure 1~3 , a dry and wet garbage separation sanitation box, including a box body 1, the box body 1 includes an outer box body frame 11 and an inner loading frame 12, the inner cavity of the inner loading frame 12 is provided with a sundry carrying cavity 13, the Sliding rails 14 are arranged on the sides of the inner cavity of the sundries carrying chamber 13, and a water filter screen 15 is arranged between the slide rails 14 on the left and right sides. 14, the bottom of the filter screen 15 is also provided with a filtrate collection cavity bucket 18, and the filtrate collection cavity bucket 18 is arranged directly below the space position of the water filter screen plate 15, and the two sides of the filtrate collection cavity bucket 18 A side edge plate 17 is provided at the end, and a fixed piece 16 is arranged on the inner wall of the box body 1. The side edge plate 17 and the fixed piece 16 are fixedly installed, and the bottom of the filtrate collection ...

Embodiment 2

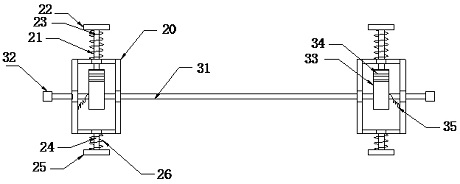

[0028] see figure 2 , this embodiment is a further optimization of Embodiment 1. On the basis of it, a transverse strut 31 is arranged between the medium vibrating frame 20 on the same side, and the two ends of the transverse strut 31 are fixedly installed on the box by fixing bolts 32. In the inner cavity of the body 1, a toggle block 33 is arranged on the transverse strut 31, and the toggle block 33 is respectively located in the inner cavity of the corresponding medium vibration frame 20. The upper edge of the toggle block 33 is provided with a corrugated block 34, and the bottom end of the upper edge support rod 21 is inserted into the corrugated block 34, and a built-in Buffer spring 35.

[0029] For the medium vibrating frame 20, the application design is provided with a transverse strut 31 between the medium vibrating frames 20, and a toggle block 33 is set in the inner cavity of the medium vibrating frame 20, through the corrugated structure on the toggle block 33 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com