External feeding system

A material container and material channel technology, used in closing, packaging, sealing parts with auxiliary devices, etc., can solve problems such as affecting medical staff to observe medical waste liquid, sealing falling into, pipeline blockage, etc. The effect of complex, easy to manufacture and few components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

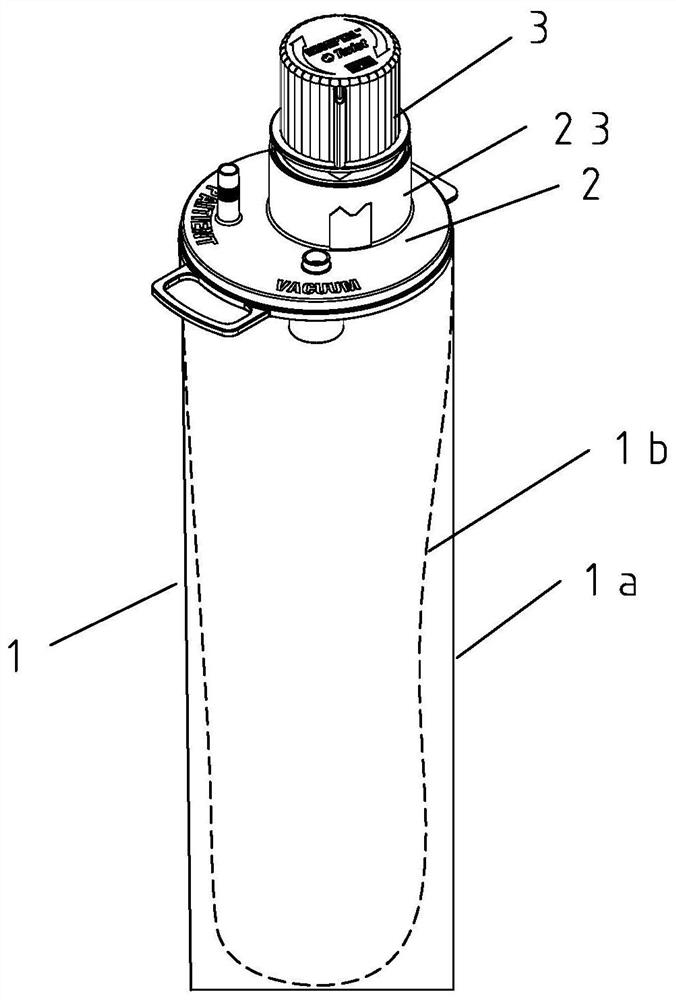

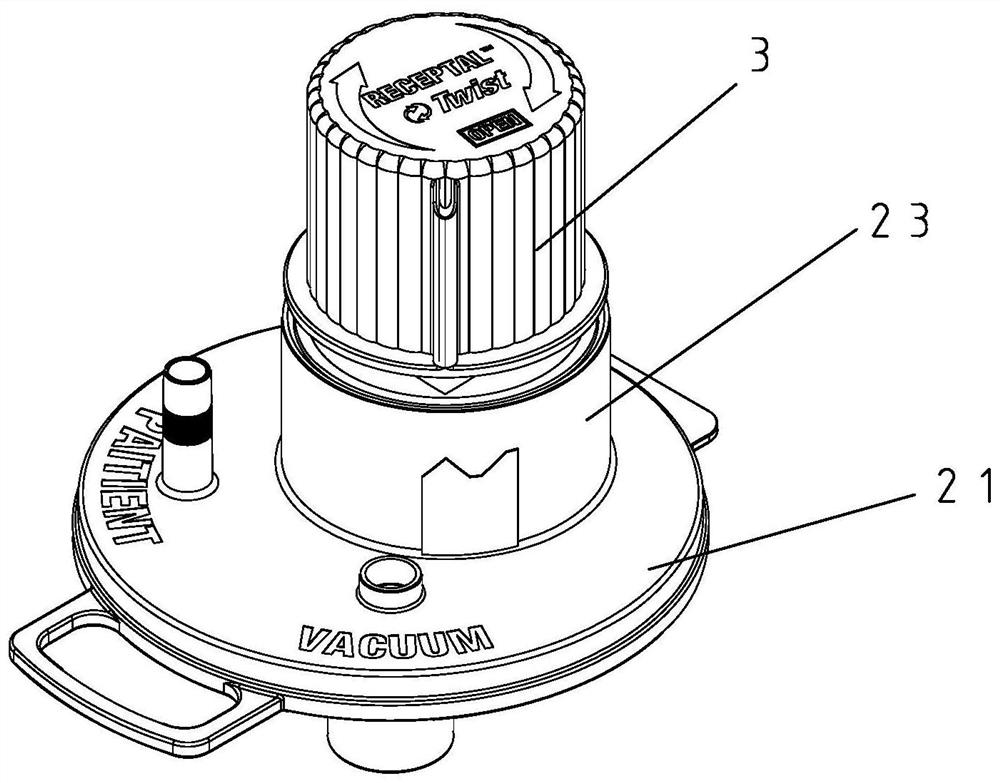

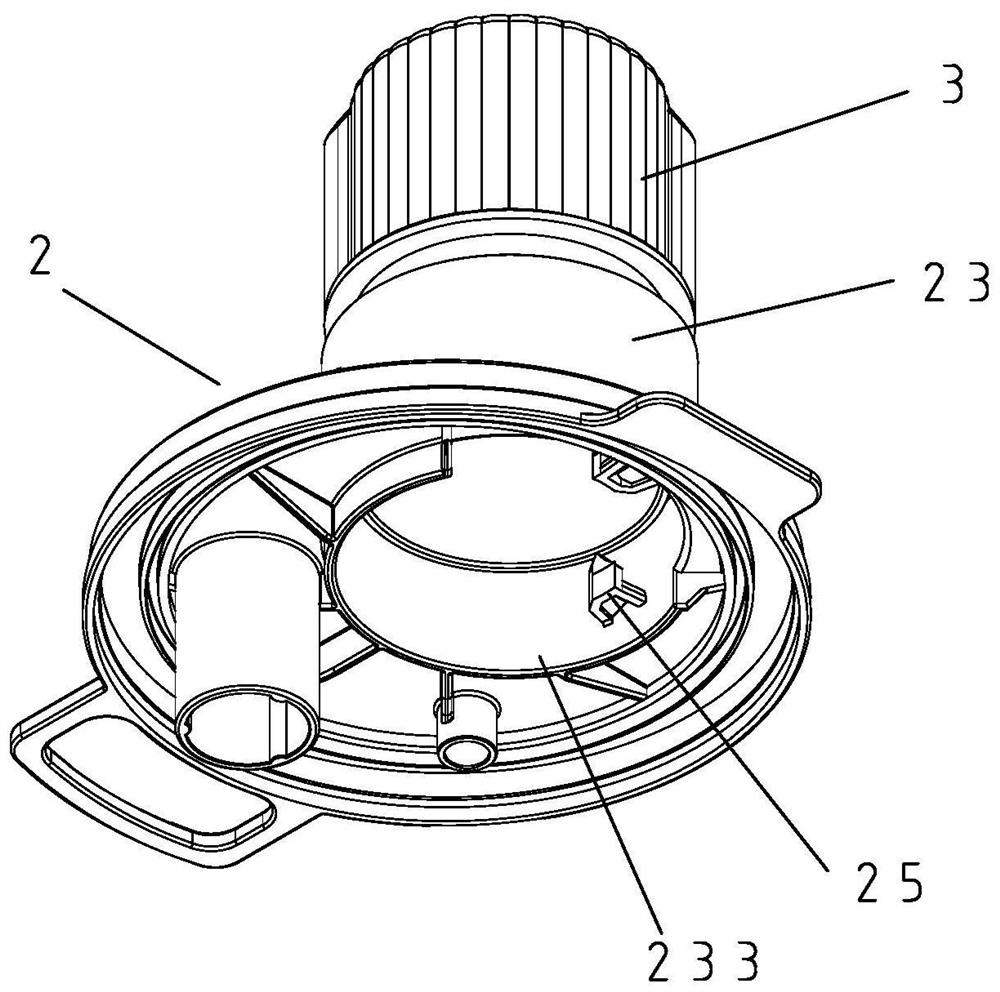

[0016] see Figure 1 to Figure 11 . The external feeding system according to the first embodiment of the present invention includes a receiving container 1 , a top cover 2 and a feeding container 3 .

[0017] The top cover 2 is covered on the upper end of the material receiving container 1 . The top cover 2 includes a top cover body 21 and a feeding joint 23. The shape of the feeding joint 23 is approximately tubular.

[0018] The lower end of the feeding container 3 is provided with a material outlet 33 and a seal 34 for closing the material outlet 33 . The sealing 34 is preferably a film-shaped sealing, and the material of the film-shaped sealing can be, for example, an aluminum foil film or the like. The lower end of the feeding container 3 is rotatably installed in the feeding channel 230 of the feeding joint 23 . The side of the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com