Cloth perforating machine

A punching machine and fabric technology, applied in the textile field, can solve the problems of affecting the punching accuracy, increasing labor costs, affecting the continuous operation of the machine, etc., achieving the effect of simple structure and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

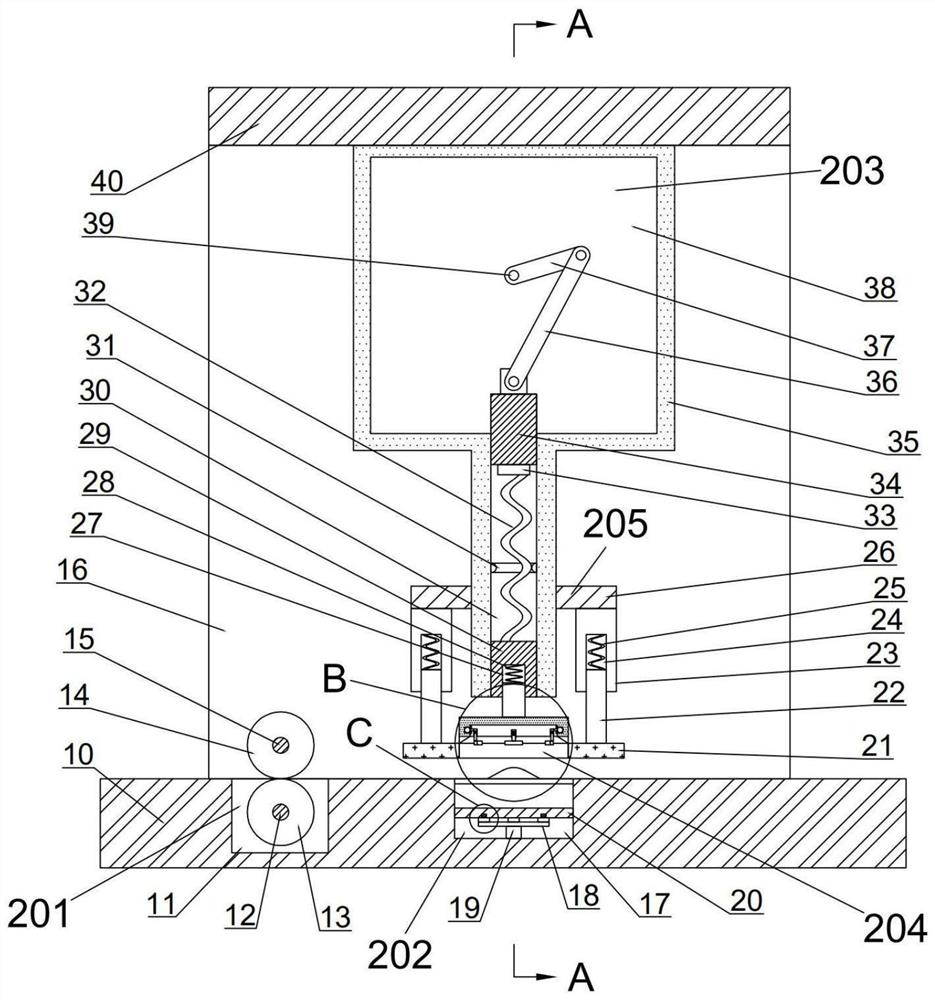

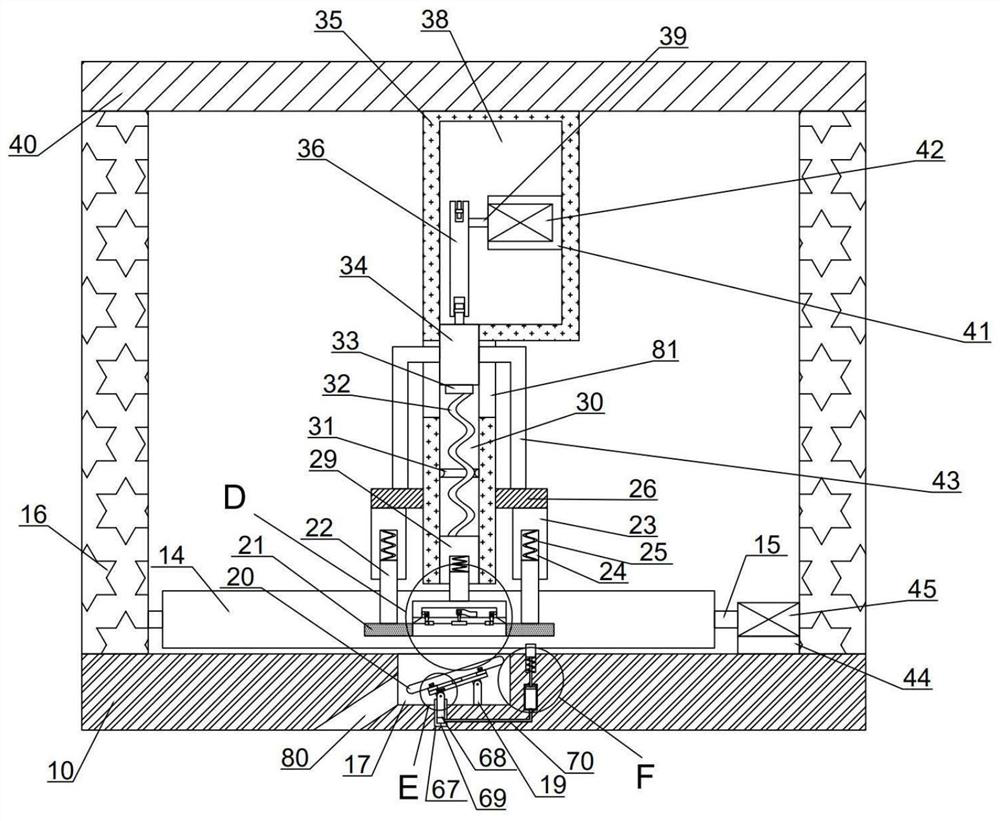

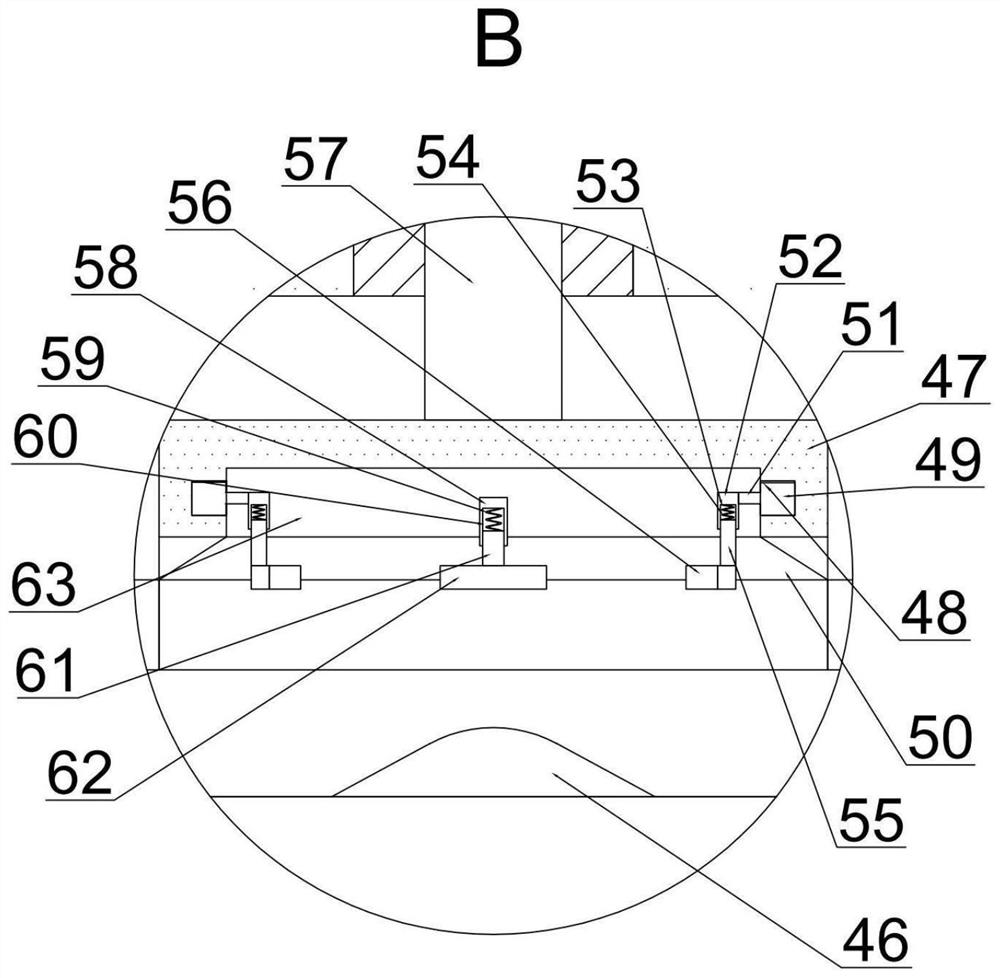

[0021] Such as figure 1As shown, a fabric punching machine includes a body 10, two first support plates 16 are fixedly fixed on the front and back sides of the upper side of the body 10, and second support plates are fixedly arranged on the upper ends of the two first support plates 16. plate 40, the body 10 is provided with a feed trough 11, the feed chute 11 is provided with a feed device 201 for conveying cloth, the body 10 is provided with an auxiliary punching groove 17, and the auxiliary punching The hole slot 17 is located on the right side of the feeding slot 11, the auxiliary punching slot 17 is provided with a discharge device 202 for discharging waste, and the lower side of the second support plate 40 is fixedly provided with a punching case 35, A power space 38 is provided in the perforated housing 35 , and a first chute 30 with an open lower end is also provided in the perforated housing 35 , the first chute 30 is located at the lower side of the power space 38 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com