An automatic welding system for long and straight box-like structural parts

A technology for automatic welding and structural parts, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of poor adjustment accuracy, poor precision, and low efficiency, and achieve welding deformation, reasonable structural design, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

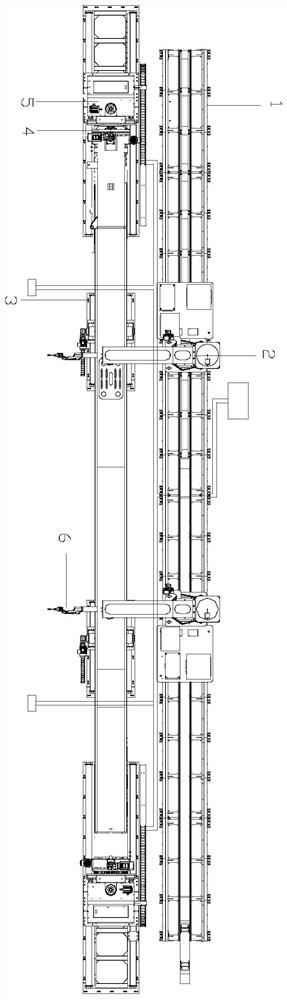

[0021] like Figure 1-7 As shown, this specific embodiment adopts the following technical solutions: it includes an elongated floor rail module 1, an external shaft module 2, a support tool assembly 3, a positioning module 4, a positioner module 5 and a welding module 6, and the elongated floor rail The module 1 is arranged in parallel with the support tool assembly 3, the external shaft module 2 is installed on the elongated ground rail module 1, the end of the external shaft module 2 is installed with a welding module 6, and the positioning module 4 is installed on the positioner module 5, The positioner module 5 is mounted on the support tool assembly 3 .

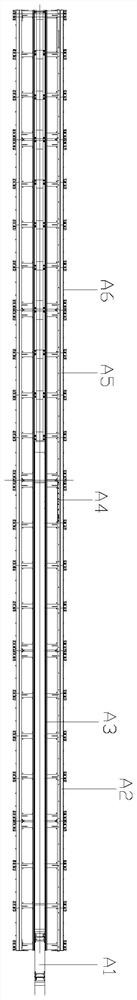

[0022] The lengthened ground rail module 1 is composed of a drag chain A1, a base body A2, a guide groove A3, a straight-toothed rack A4, a guide rail A5, and a ground rail shield A6. The guide groove A3 is laid on the base body A2. The drag chain A1 is installed in A3, the straight rack A4 and the guide rail A5 are lai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com