Warehouse logistics management method, system and device and storage medium

A logistics management and warehouse technology, applied in the field of warehouse logistics management, can solve the problems of inconvenience in picking up goods, reducing logistics and transportation efficiency, improper arrangement of warehouse storage locations, etc., and achieving the effect of convenient goods management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

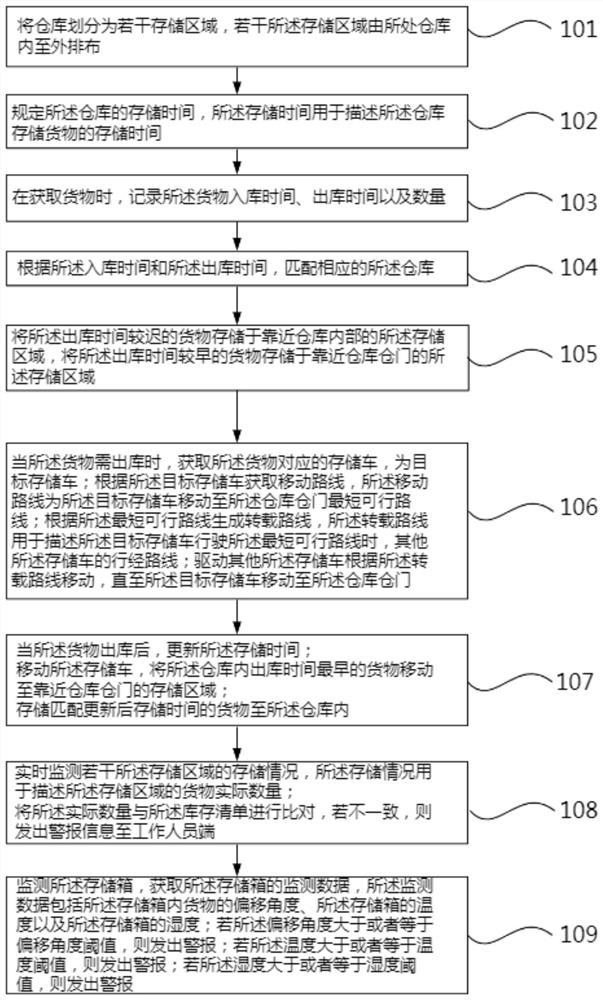

[0096] A warehouse logistics management method, refer to figure 1 ,include:

[0097] 101. Divide the warehouse into several storage areas, and the several storage areas are arranged from inside to outside of the warehouse.

[0098] Specifically, the warehouse is divided into several storage areas, each storage area has the same area and shape, and is arranged in a matrix. For example, the warehouse is divided into 9 storage areas, each column is provided with 3 storage areas, and each row is provided with 3 storage areas; and the storage areas are divided from those close to the inside of the warehouse to those close to the outside of the warehouse.

[0099] Optionally, the different storage areas are marked, specifically by numbers 1 to 9, number 1 indicates the storage area closest to the warehouse door, and number 9 indicates the storage area closest to the interior of the warehouse.

[0100] 102. Specify the storage time of the warehouse, where the storage time is used t...

Embodiment 2

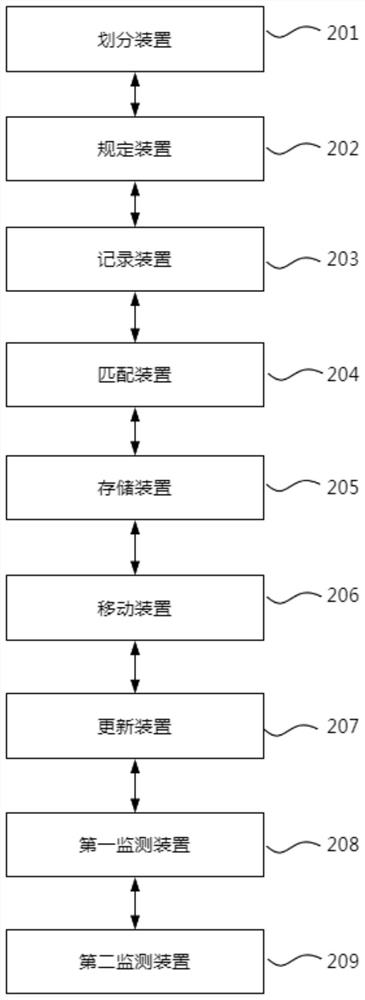

[0151] A warehouse logistics management system, refer to figure 2 ,include:

[0152] The division device 201 divides the warehouse into several storage areas, and the storage areas are arranged from inside to outside of the warehouse.

[0153] The specifying means 202 specifies the storage time of the warehouse, and the storage time is used to describe the storage time of goods stored in the warehouse.

[0154] The recording device 203, when acquiring the goods, records the storage time, time and quantity of the goods.

[0155] The matching device 204 matches the corresponding warehouses according to the storage-in time and the storage-out time.

[0156] The storage device 205 stores the goods with a later departure time in the storage area near the interior of the warehouse, and stores the goods with an earlier departure time in the storage area near the warehouse door.

[0157] The mobile device 206, when the goods need to be out of the warehouse, acquires the storage vehi...

Embodiment 3

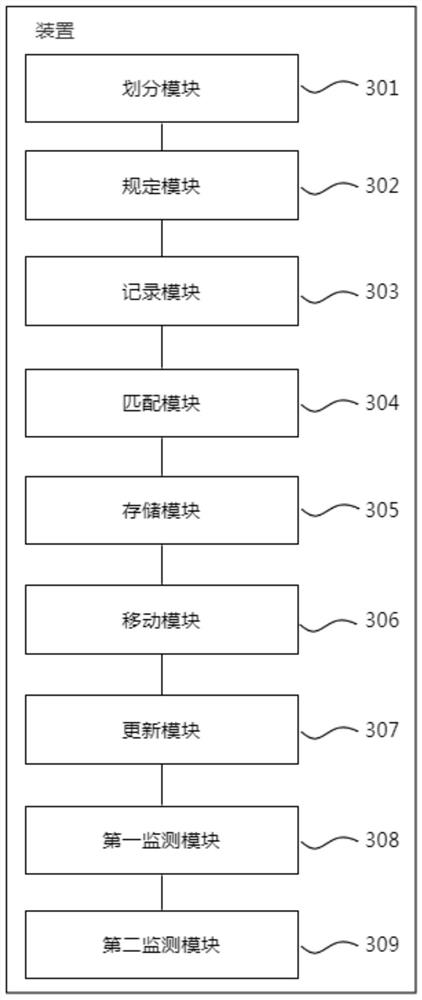

[0171] A warehouse logistics management device, refer to image 3 ,include:

[0172] The division module 301 divides the warehouse into several storage areas, and the storage areas are arranged from inside to outside of the warehouse.

[0173] The specification module 302 specifies the storage time of the warehouse, and the storage time is used to describe the storage time of the goods stored in the warehouse.

[0174] The recording module 303, when obtaining the goods, records the time of entering the warehouse, the time of leaving the warehouse and the quantity of the goods.

[0175] The matching module 304 matches the corresponding warehouse according to the storage time and the storage time.

[0176] The storage module 305 stores the goods with a later departure time in the storage area near the interior of the warehouse, and stores the goods with an earlier departure time in the storage area near the warehouse door.

[0177] The moving module 306, when the goods need t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com