Automatic counting rammer and counting method

A technology of automatic counting and counting methods, applied in counting mechanisms/items, soil protection, tension measurement, etc., can solve problems such as unguaranteed construction safety, impact on engineering construction, and inability to know operation information in time, achieving Easy to monitor and manage the effect in real time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

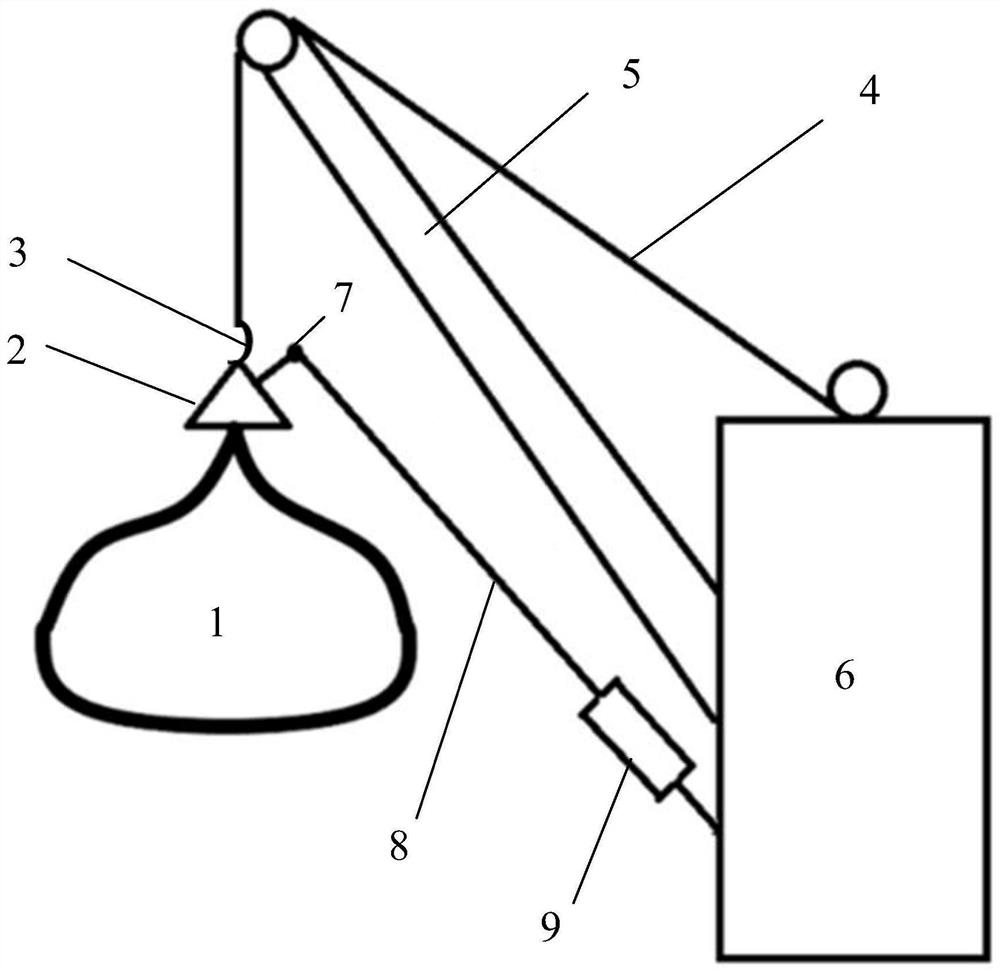

[0017] Example: as attached figure 1 As shown, a ramming machine with automatic counting includes a tamper 1, a hanging and unhooking device 2, a hook 3, a lifting wire 4, a support arm 5, a control room 6, a decoupling 7, a decoupling steel wire 8 and a tension sensor 9. A support arm 5 with a pulley on the top is provided outside the control room 6 obliquely upwards. The lifting wire 4 drawn from the control room 6 passes through the pulley and is installed with a hook 3 to hang and release the hook device 2, and fix it under the hang and release hook device 2 Equipped with a tamper 1, the tamper 1 is lifted up and down in the vertical direction under the control of the lifting wire 4; the decoupling device 2 is provided with a decoupling 7, and the decoupling steel wire 8 drawn from the control room 6 is hooked on the decoupling 7, a tension sensor 9 is installed on the decoupling steel wire 8 for real-time detection of the tension of the decoupling steel wire 8, and the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com