Electric heating extrusion disc magneto-rheological and electromagnetic bearing bush friction combined transmission device

A transmission device and magneto-rheological technology, applied in the field of power transmission, can solve the problems of limited transmission torque, reduced transmission efficiency, and performance degradation of magneto-rheological fluids, so as to increase shear yield stress, enhance extrusion force, and improve The effect of torque transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

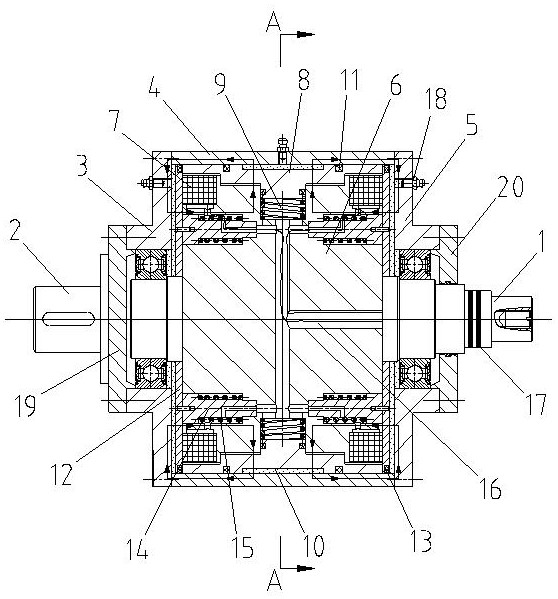

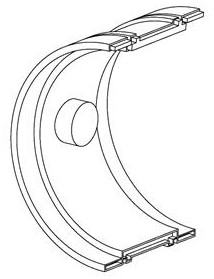

[0027] Example: see figure 1 , figure 2 as well as image 3 , an electrothermally extruded disc magneto-rheological and electromagnetic bearing pad friction combined transmission device, including a driving shaft 1, a driven shaft 2 and a transmission housing; the transmission housing includes a left end cover 3, a driven circle barrel 4 and right end cover 5; wherein, the left end cover 3 and the right end cover 5 are fixedly connected with the driven cylinder 4 through connecting screws, and the middle parts of the left end cover 3 and the right end cover 5 are respectively provided with a bearing hole, and the bearing hole is connected with the driven cylinder 4. The moving cylinder 4 is set on the coaxial center line. The drive shaft 1 extends into the housing after passing through the right end cover 5, and is connected with the left end cover 3 and the right end cover 5 through bearings, and the part of the drive shaft 1 located in the driven housing is expanded to form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com