Roadbed ventilation prefabricated part in flexible splicing form

A technology of prefabricated components and forms, applied in roads, roads, buildings, etc., can solve problems such as poor heat dissipation uniformity and control uniformity, decreased ventilation and cooling efficiency, and loss of ventilation capacity, etc., to achieve enhanced long-term ground temperature control effects, resistance The ability to enhance the uneven deformation of frozen soil, the effect of easy realization and promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in combination with specific embodiments.

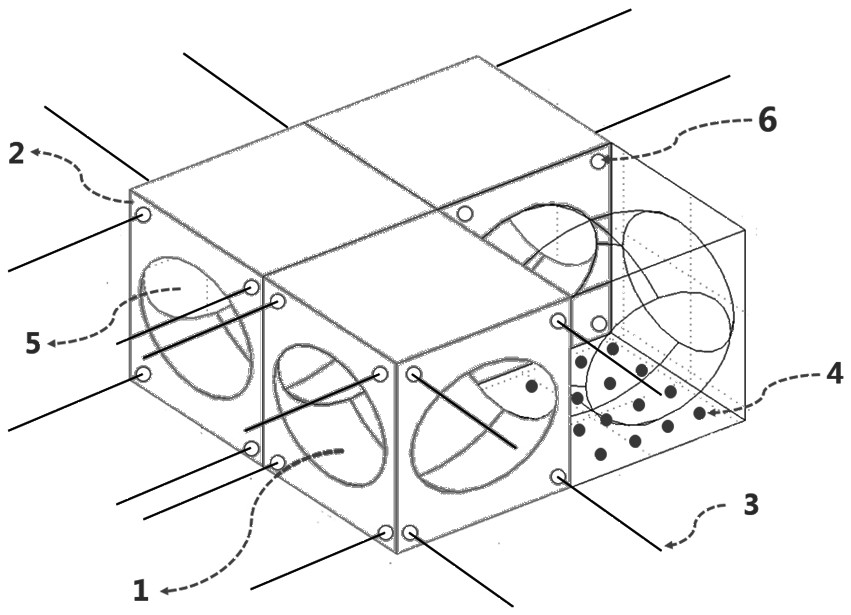

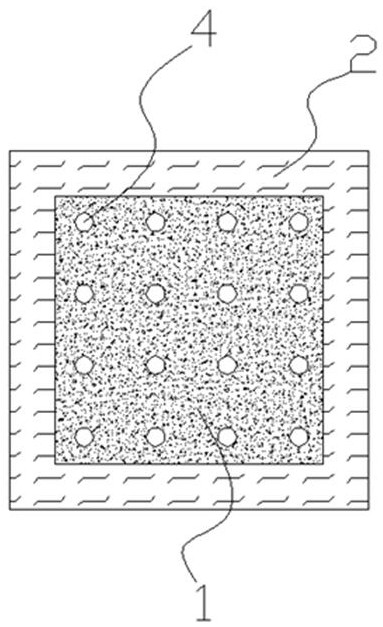

[0025] The invention relates to a prefabricated component for subgrade ventilation in the form of flexible splicing. The component includes a concrete ventilation component 1. The concrete ventilation component 1 is a hollow cube. Ventilation holes 5 are opened on the front, rear, left, and right sides, and the ventilation holes 5 communicate with the central cavity. Form vertical and horizontal channels. The bottom surface of the concrete ventilation component 1 is uniformly provided with circular small holes 4 through the wall, communicating with the cavity in the middle.

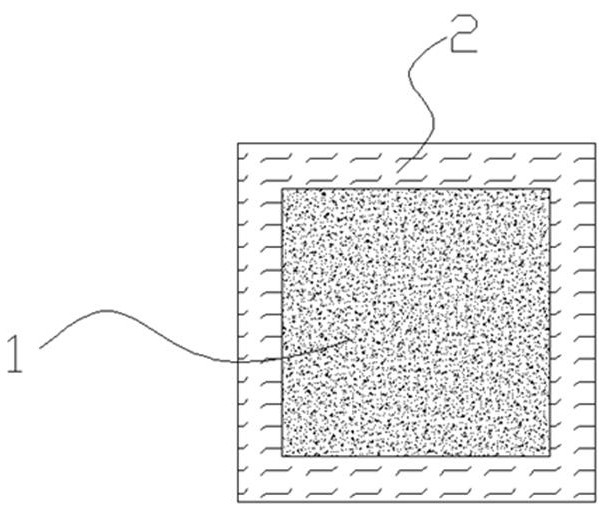

[0026] The concrete ventilating component 1 is provided with a rubber outer wrapping layer 2, and circular holes are opened on four sides.

[0027] The concrete ventilation component 1 is provided with longitudinal and transverse prestressed steel wire grouting tunnels 6 located at the edge of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com