Milanese eye sewing device

A technology for placing cylinders and placing grooves, which is applied in sewing equipment, sewing machine components, textiles and papermaking, etc., can solve the problems of low production efficiency, achieve the effects of improving production efficiency, fast and convenient position adjustment, and stable position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

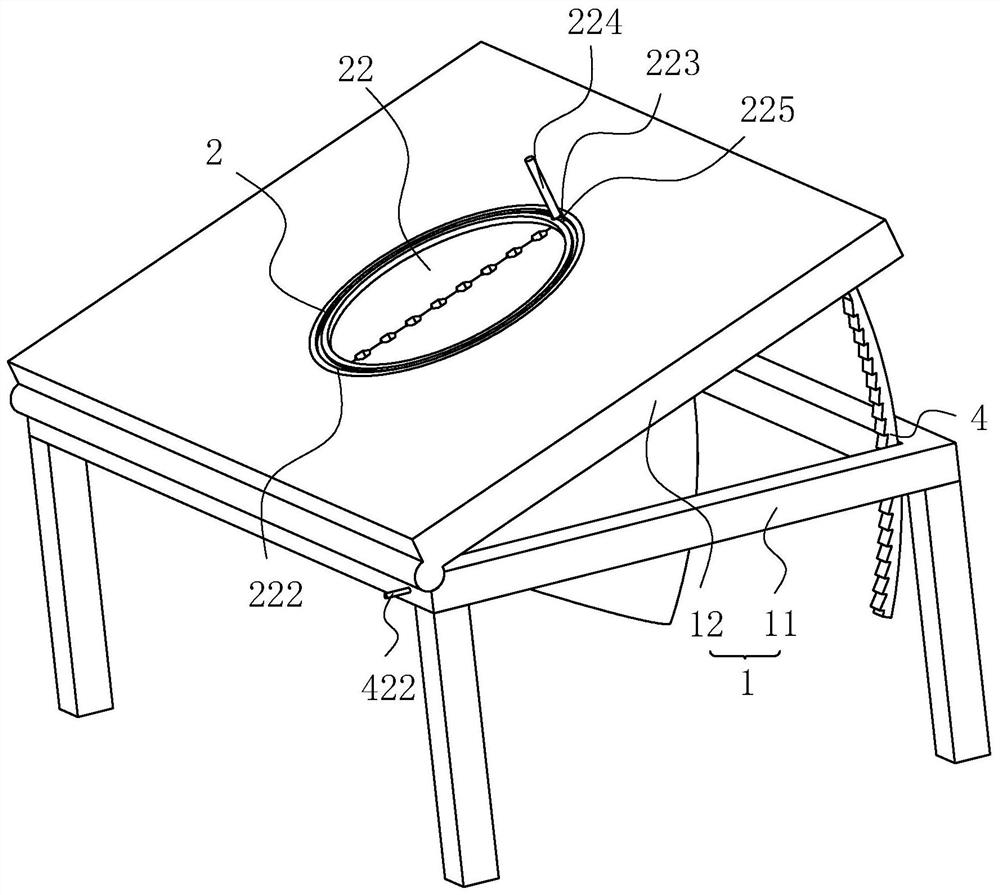

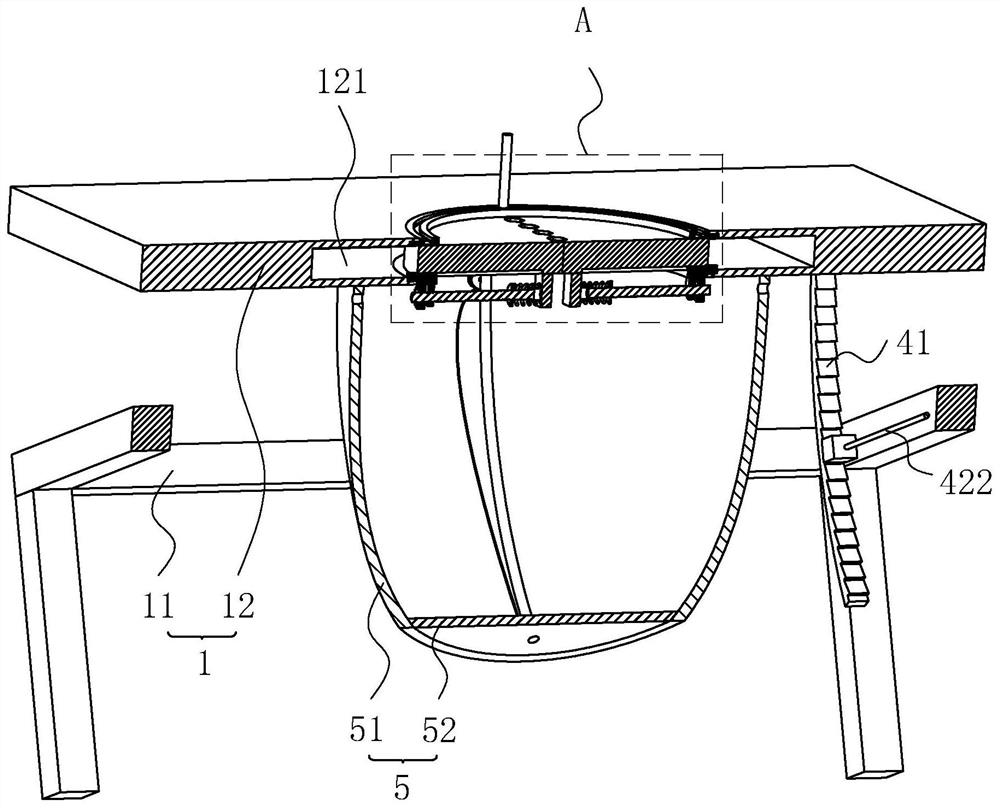

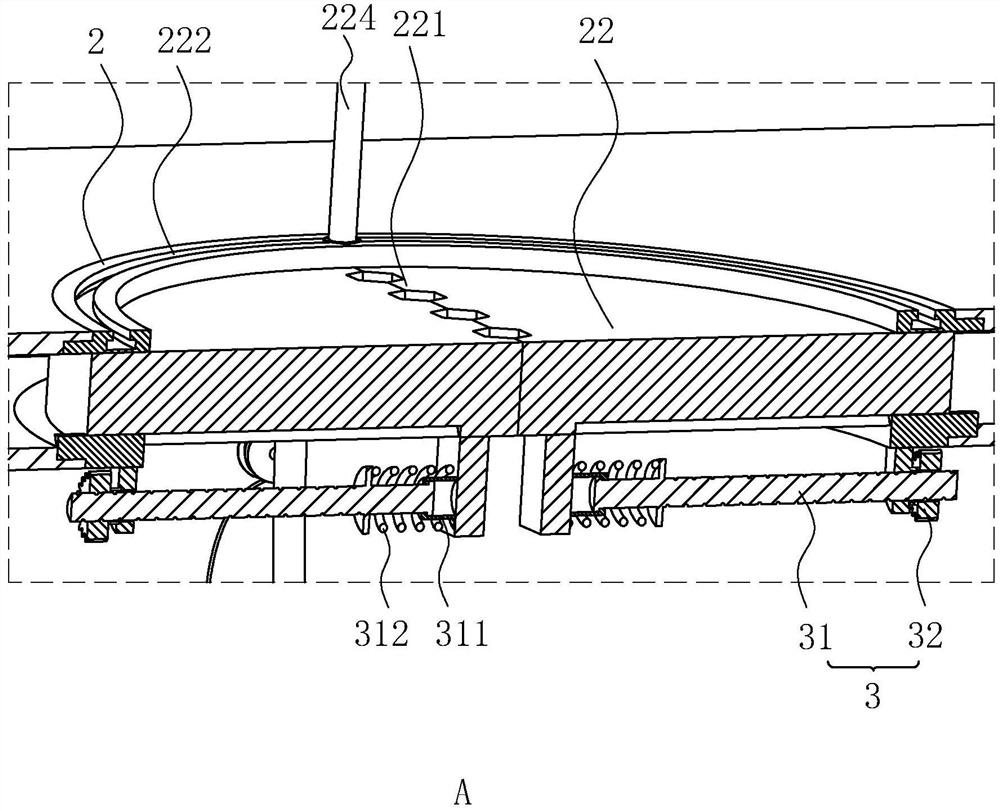

[0039] Attached to the following Figure 1-7 This application will be described in further detail.

[0040] The embodiment of the present application discloses a Milanese eye sewing device. refer to figure 1 and figure 2 The Milanese eye sewing device includes an auxiliary table body 1, the auxiliary table body 1 includes a table frame 11 and a table top 12, one side of the table top 12 is horizontally hinged to the table frame 11, and an adjustable table top 12 is connected between the table top 12 and the table frame 11 Angle adjustment device 4, the surface of the desktop 12 is rotatably connected with a rotating ring 2, the axis of rotation of the rotating ring 2 is perpendicular to the desktop 12, the middle part of the rotating ring 2 is a placement port 21 that runs through the auxiliary table body 1, and the rotating ring 2 is connected with a Two sliding doors 22 that clamp the item to be sewn. Put the item to be sewn from the placement opening 21 below the surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com