Modular drilling machining tool

A machining tool and modular technology, applied in the field of metal cutting, can solve the problems of high manufacturing cost of clamping parts, difficult to guarantee cutting accuracy, deformation and cracks, etc. to the rigid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

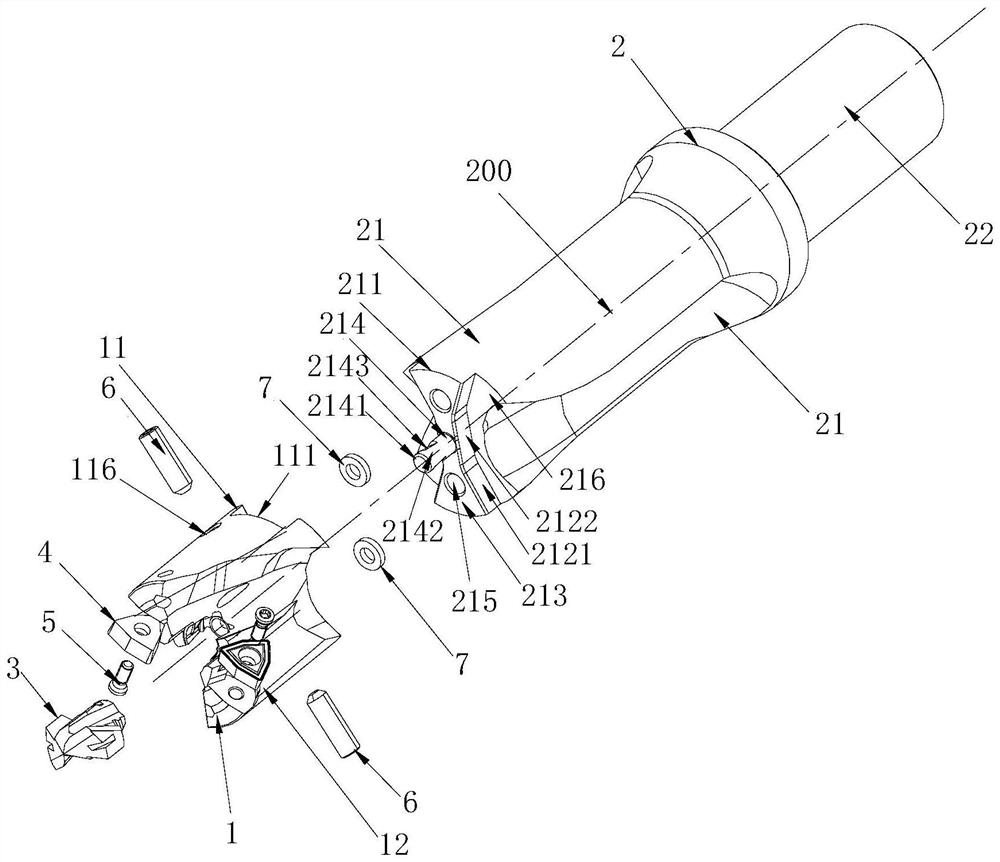

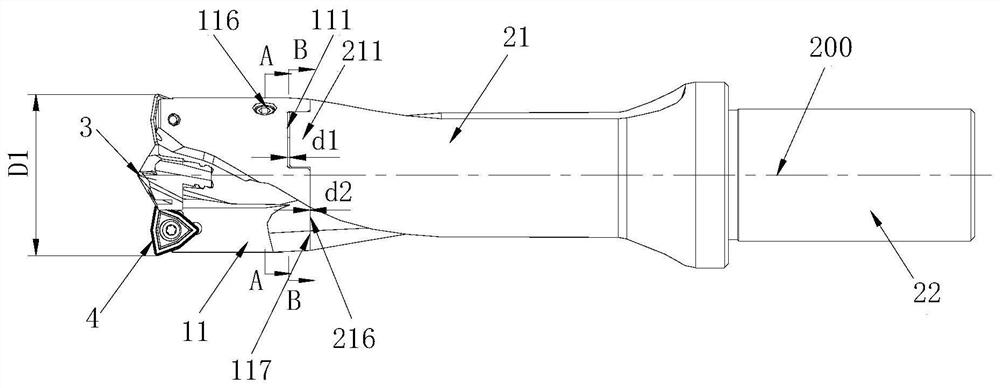

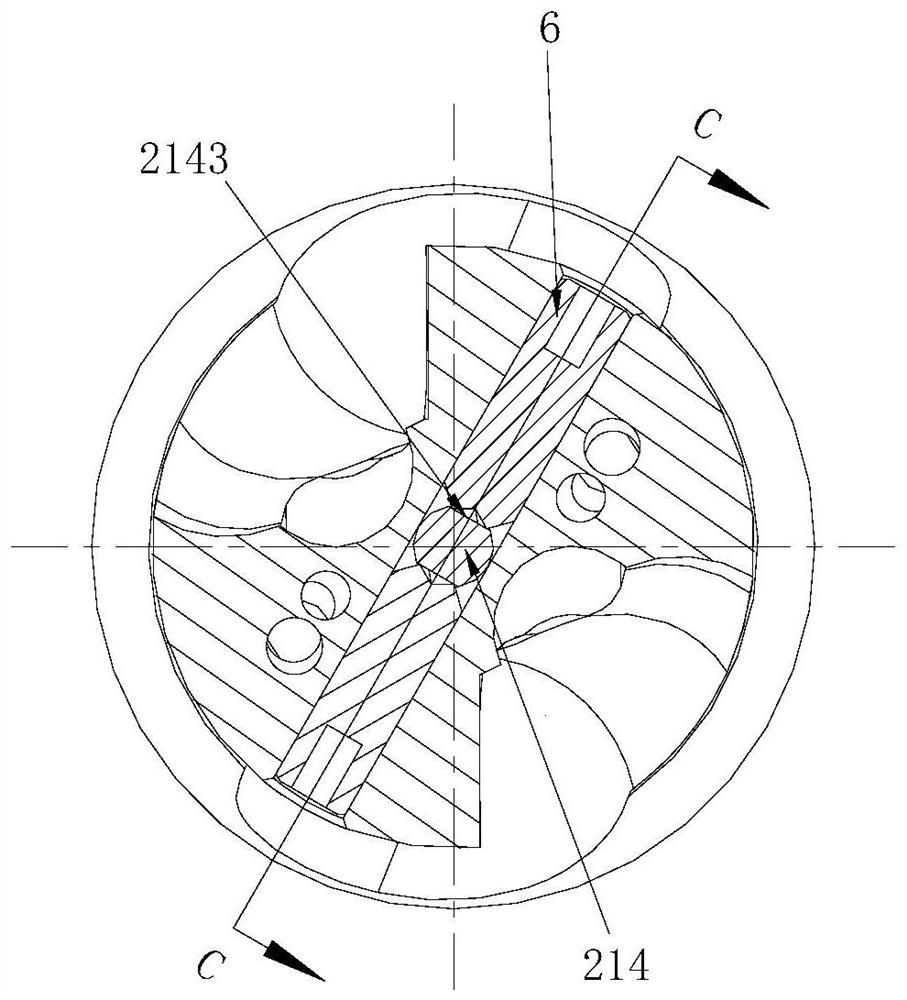

[0030] Figure 1 to Figure 6 An embodiment of the modular drilling tool of the present invention is shown, including a cutting part 1, a clamping part 2, a center drill tip 3 and two outer cutting inserts 4, and the cutting part 1 is provided with a cutting interface part 11 and the cutting part 12, the clamping part 2 is provided with a clamping interface part 21 and a clamping part 22, and the center drill point 3 and the outer cutting insert 4 are installed on the center and the circumferential position of the cutting part 12 respectively, and the two outer cutting The blade 4 is arranged on both sides of the center drill point 3 to form a complete cutting unit with the center drill point 3. The cutting interface part 11 is provided with a clamping recess 111, and the clamping interface part 21 is provided with a clamping boss 211....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com