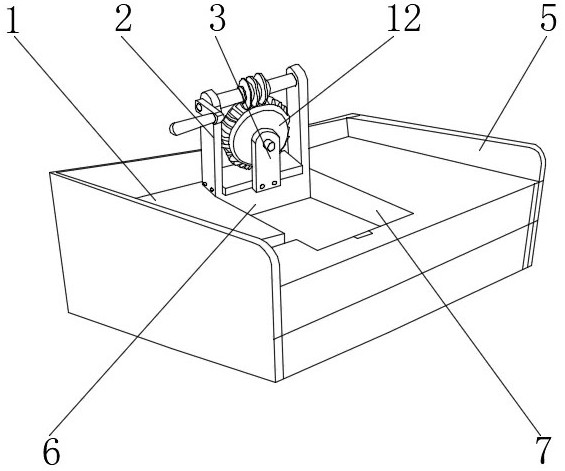

Transmission demonstration teaching aid for equipment machinery

A teaching aid and mechanical technology, which is applied in the field of demonstration teaching aids, can solve the problems of poor positioning stability, inability to disassemble and operate, and poor convenient effect, and achieve the effects of simple and convenient installation, convenient installation and positioning, and convenient connection and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

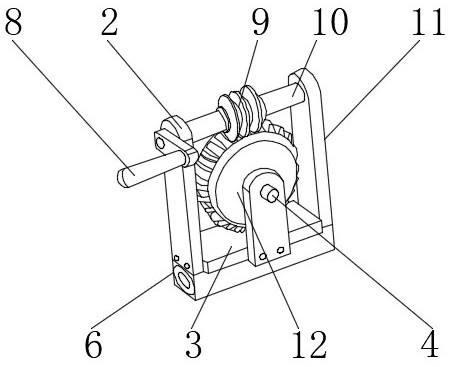

Embodiment 1

[0026] Embodiment 1, No. 1 adjusting frame 303 and No. 2 adjusting frame 308 are located on both sides of the positioning bottom plate 305, positioning pin 304 is located on the upper end of No. 1 adjusting frame 303 and No. 2 adjusting frame 308, and No. 1 positioning connecting frame 302 is located on No. 1 On both sides of the adjusting frame 303, the No. 2 positioning connecting frame 306 is positioned at both sides of the No. 2 adjusting frame 308, the positioning buckle 301 is positioned at one side of the No. 1 positioning connecting frame 302, and the positioning base 307 is positioned at the lower end of the positioning base plate 305, which can facilitate Better to disassemble and adjust the operation, the installation is simple and convenient, there are hinges between the No. 1. The inner side of the No. 2 adjusting frame 308 is flexibly connected, and a fixed block is arranged between the No. 1 positioning connecting frame 302 and the No. 1 adjusting frame 303. Fix...

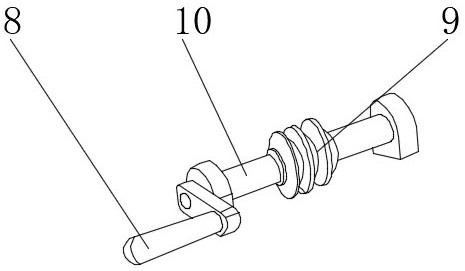

Embodiment 2

[0027]Embodiment 2, the positioning shaft 603 is located inside the movable block 601, the rotating shaft 602 is located at both ends of the positioning shaft 603, the connecting card base 604 is located at the upper end of the movable block 601, the mounting frame 605 is located at the upper end of the connecting card base 604, and the fixed frame 606 is located at the upper end of the connecting card base 604. The upper end of the mounting bracket 605 can facilitate the installation and positioning operation, and is convenient for adjusting the teaching aid. A welding block is arranged between the positioning shaft 603 and the rotating shaft 602. The two ends of the positioning shaft 603 are fixedly connected to the inner side of the rotating shaft 602 through the welding block. A welding seat is arranged between the movable block 601 and the mounting frame 605, and the upper end of the movable block 601 is fixedly connected with the lower end of the mounting frame 605 through...

Embodiment 3

[0028] Embodiment 3, the handle slot 701 is located on one side of the placement slot 702, the protective pad 705 is located on the inner side of the placement slot 702, the telescopic plate 704 is located at the rear end of the placement slot 702, and the buckle 703 is located at the front end of the telescopic plate 704, which can facilitate Putting and protecting the teaching aids has a good dust-proof effect. A hinge is arranged between the expansion plate 704 and the placement groove 702. The rear end of the placement groove 702 is movably connected to the lower end of the expansion plate 704 through the hinge, and the buckle 703 is connected to the telescopic A clip is provided between the plates 704, and the front end of the telescopic plate 704 is fixedly connected to one side of the buckle 703 through the clip, which has a good dustproof effect and saves space.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com