Welding laser head coaxial vision lens group and welding laser coaxial system

A laser head and laser focusing mirror technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of the welding surface cannot be observed in real time, cannot be inspected in real time, and the welding quality cannot be judged, so as to reduce the influence of heat, The effect of improving welding accuracy and efficiency and increasing welding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following examples are further explanations and supplements to the present invention, and will not constitute any limitation to the present invention.

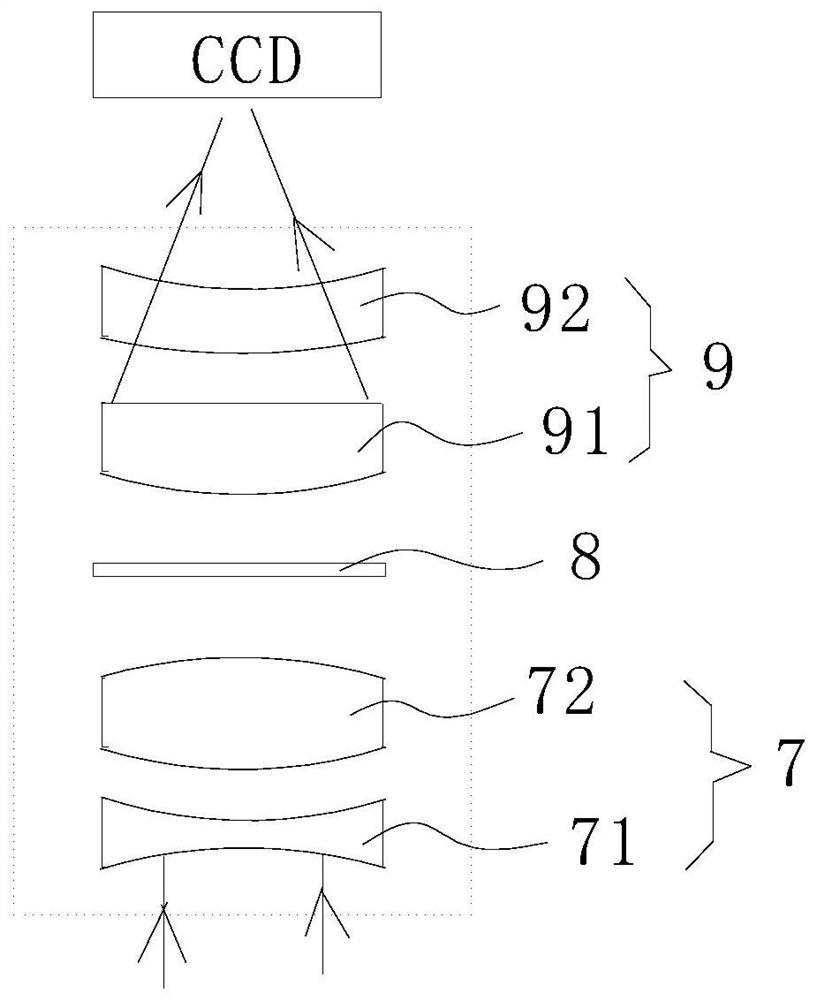

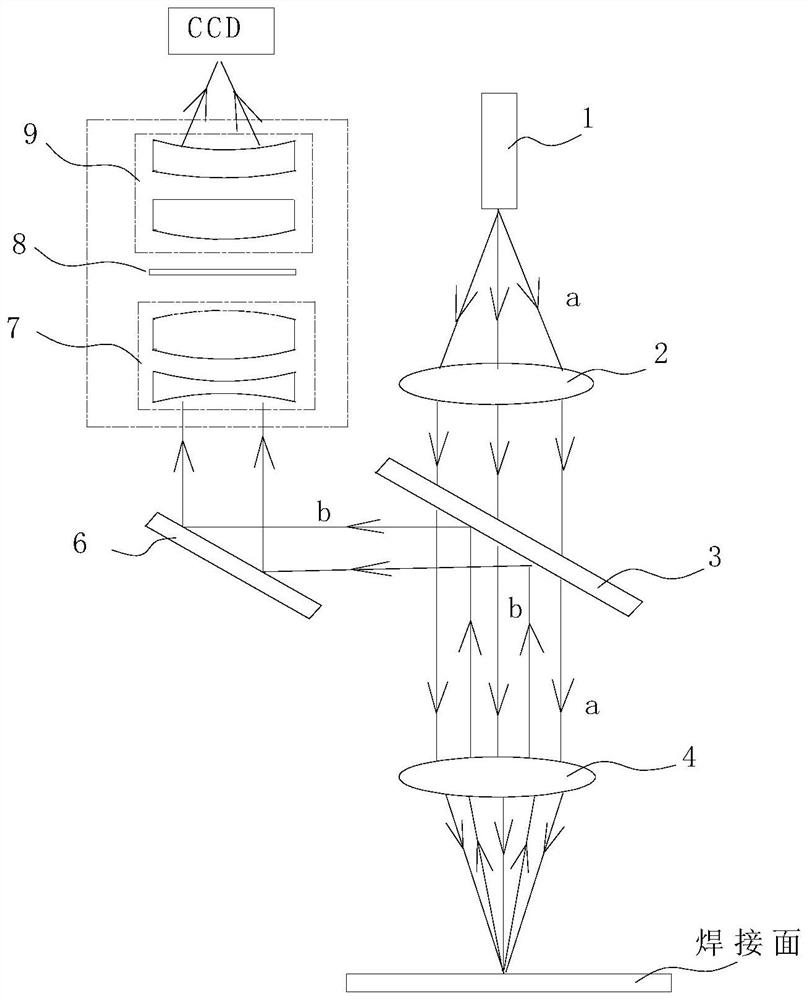

[0024] Such as figure 1 Shown, a kind of welding laser head coaxial visual lens group, comprises: the imaging objective lens 7 that is made up of the first positive and negative lens group, the imaging eyepiece 9 that is made up of the second positive and negative lens group and variable diaphragm 8; The imaging objective lens 7 and the imaging eyepiece 8 are symmetrical with respect to the iris 9 ; imaging light enters the imaging eyepiece 9 from the imaging objective 7 and the iris 8 in sequence.

[0025] This design adopts mirror groups with symmetrical achromatic structure, that is, the first positive and negative lens groups and the second positive and negative lens groups are symmetrical with respect to the variable diaphragm, and the positive lens in the positive and negative lens groups produces negative sph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com