Valley electricity heat storage steam boiler system

A technology of steam boiler and heat storage, which is applied in steam central heating system, heating system, steam generation, etc., which can solve problems such as increasing economic expenditure, causing smog, and unstable power generation load of small thermal power plants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

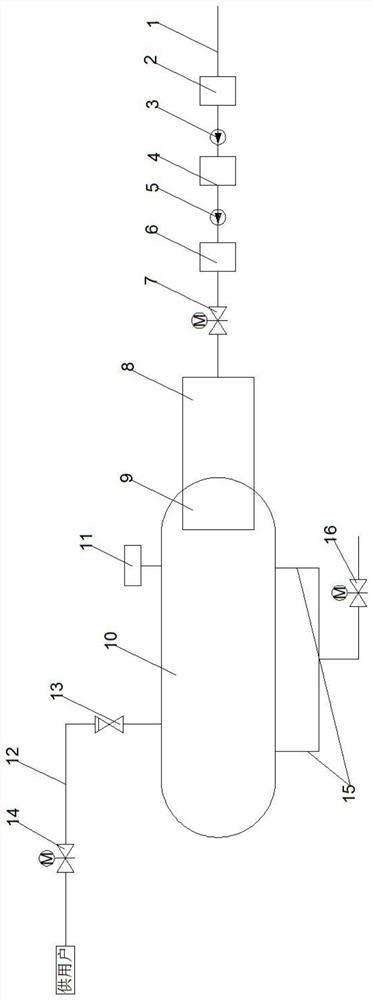

[0015] Such as figure 1 As shown, a valley electricity thermal storage steam boiler system of the present invention is installed in sequence according to the water flow direction on the water treatment system 2 on the water inlet pipe 1, the water treatment water supply pump 3, the softened water tank 4, the softened water supply pump 5, and the liquid level gauge 6 And the water inlet pipeline electric valve 7, the water inlet pipeline electric valve 7 is connected with the vapor-liquid phase change steam heat storage tank 10 through the electric steam boiler 8, and the gas-liquid phase change steam heat storage tank 10 is connected with the electric steam boiler 8 A vapor-liquid conversion device 9 is provided at the end, and a steam supply pipeline 12 is installed on the upper left end of the vapor-liquid phase change steam heat st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com