A deployable nozzle using flexible materials and an external truss structure

A technology of truss structure and flexible materials, which is applied in the field of aerospace, can solve problems such as the decline of propulsion efficiency, achieve the effects of improving reliability, reducing redundant volume and quality, and realizing high compensation characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0030] The invention provides an expandable nozzle using flexible materials and an external truss structure, which includes a rigid section of a submerged flexible nozzle, a rear head of a combustion chamber, a flexible nozzle truss structure and a flexible section of the nozzle.

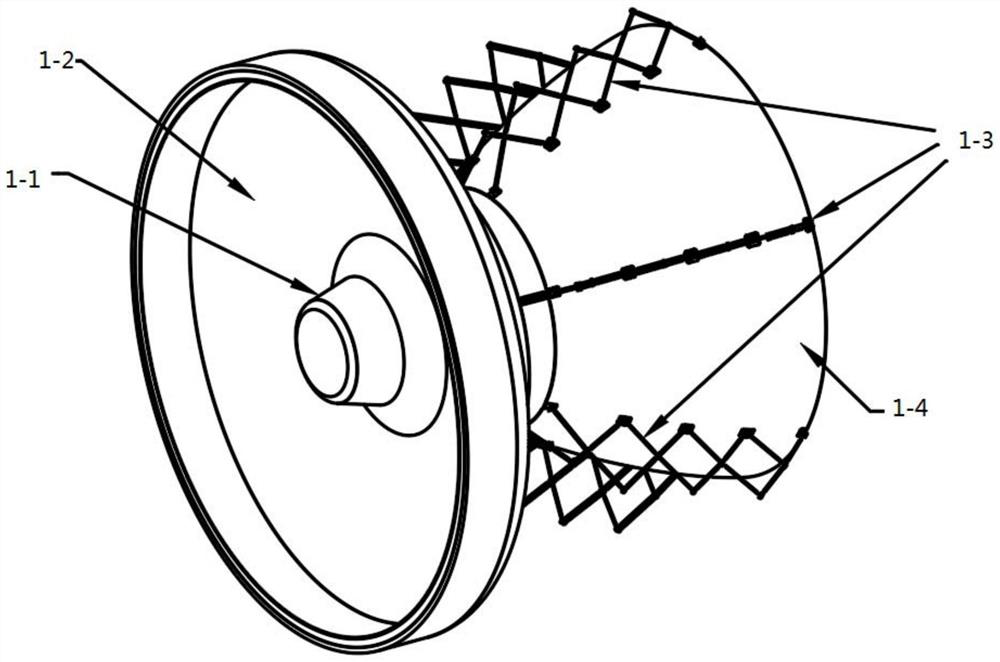

[0031] figure 1 The overall structure of the flexible nozzle is shown.

[0032] see figure 1 , where 1-1 is the rigid section (fixed section) of the submerged flexible nozzle, 1-2 is the rear head of the combustion chamber, 1-3 is the truss structure of the flexible nozzle, and 1-4 is made of multi-layer anti-ablation material composed of nozzle flexible segments.

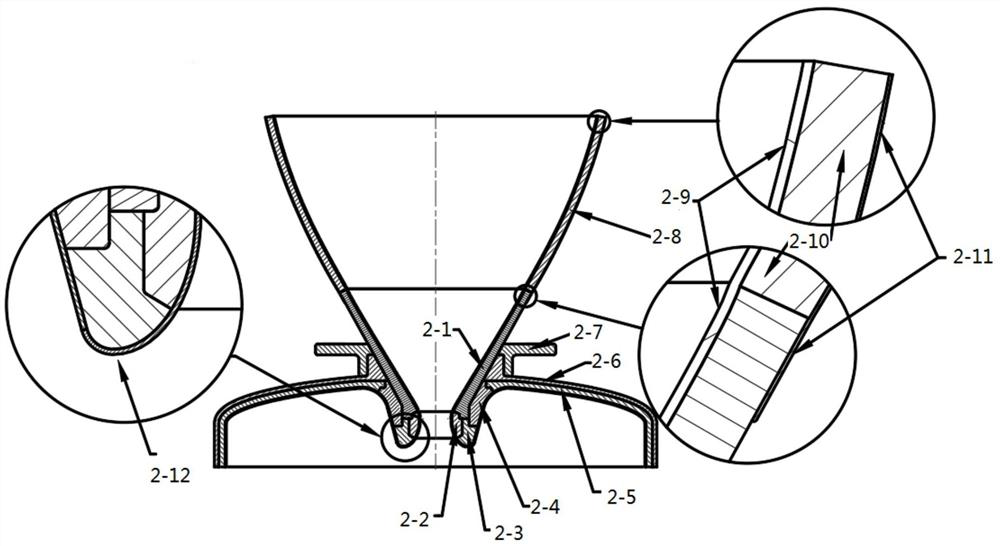

[0033] figure 2 is a cross-sectional view of the nozzle base without the truss structure.

[0034] see figure 2 , where 2-1 is the rigid expansion section, 2-2 is the throat lining, 2-3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com