Soil nail, side slope reinforcing structure and construction method thereof

A technology for strengthening structures and construction methods, which is applied in basic structure engineering, excavation, drainage structures, etc., can solve the problems of insufficient uplift bearing capacity of soil nails, unsatisfactory reinforcement effect, and low construction efficiency of soil nails, so as to shorten the construction period. , excellent cold resistance, the effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

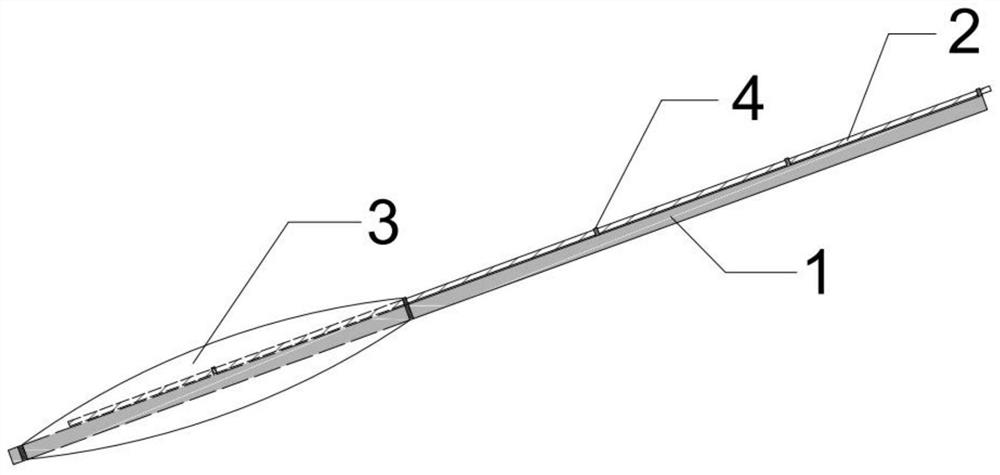

[0045] A soil nail, comprising a core material 1, a grouting pipe 2, a separation bag 3 and several collars 4, the separation bag 3 is fixedly sleeved on the bottom end of the core material 1, and the plurality of collars 4 are fixed on On the side wall of the core material 1 , the grouting pipe 2 is inserted into the partition bag 3 through several collars 4 .

[0046] Further, the bottom end of the core material 1 is set through the partition bag 3 and has a certain extension length at the end of the partition bag 3 . Both ends of the separation bag 3 are fixed on the core material 1. Preferably, the core material 1 (including the collar 4 at the connection) and the separation bag 3 are connected by welding and steel wire binding.

[0047] Further, the plurality of collars 4 are evenly welded and fixed on one side of the core material 1 , preferably, the distance between the collars 4 on the core material 1 is 1 m.

[0048] Further, the bottom end of the grouting pipe 2 is ...

specific Embodiment approach 2

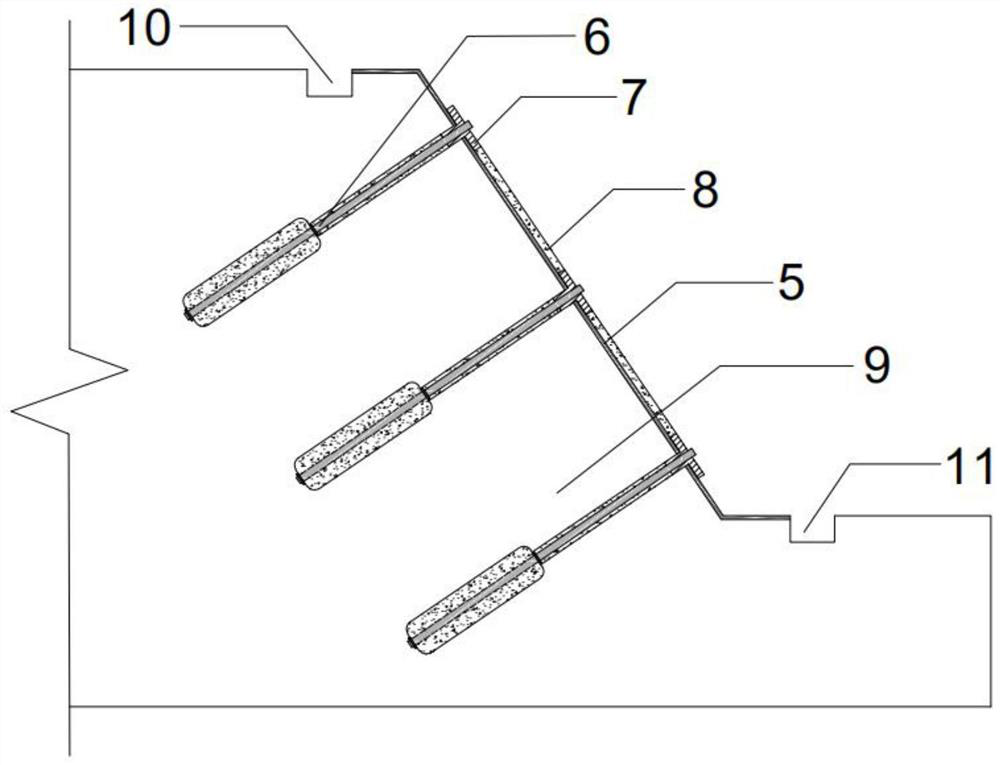

[0052] A slope reinforcement structure comprising the soil nails described in Embodiment 1, comprising a concrete spray layer 5, several soil nails 6, several end connection control members 7 and several prefabricated tie beams 8, the concrete The primary spraying layer 5 is arranged on the surface of the slope body 9, and the several soil nails 6 are inserted into the slope body 9 through the concrete primary spraying layer 5, and the top of each soil nail 6 is controlled by an end connection. The components 7 are fixed, and the adjacent end connection control components 7 are all fixedly connected by prefabricated tie beams 8 . The end connection control member 7 also plays the role of fixing the large-diameter soil nail 6 and connecting the prefabricated tie beam 8 .

[0053] Preferably, the basic unit of the layout shape of the several prefabricated tie beams 8 in the slope reinforcement structure is an equilateral triangle.

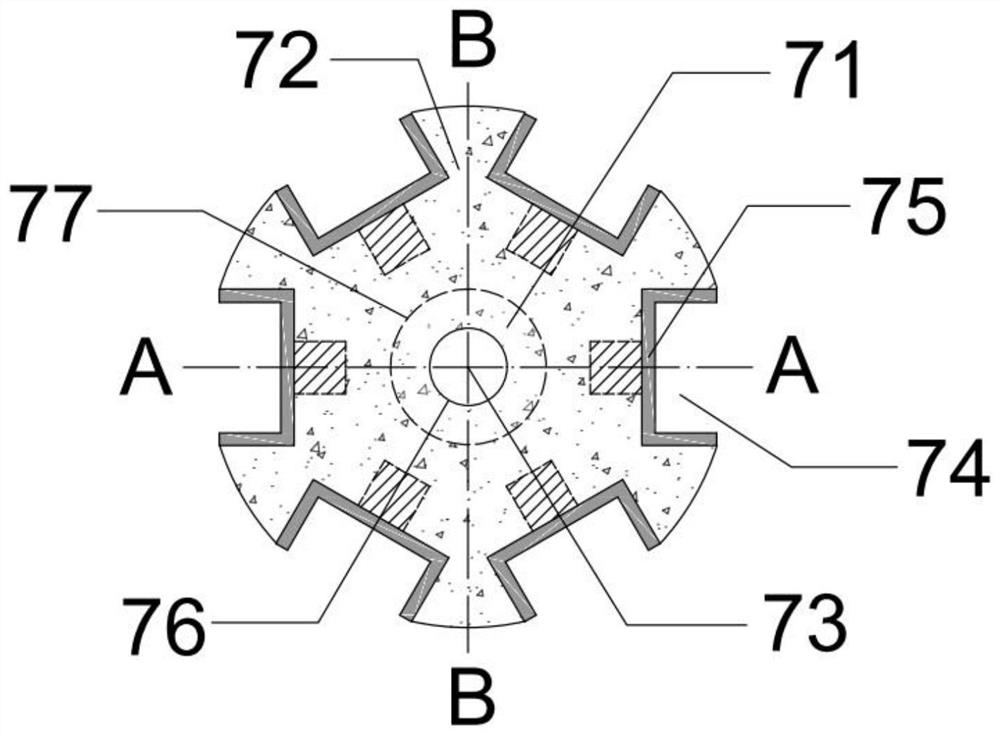

[0054]Further, each of the end connection con...

specific Embodiment approach 3

[0060] A construction method of the slope reinforcement structure described in the second embodiment, comprising the following steps:

[0061] Step 1. Carry out geological survey on the railway slope, design the specific size and quantity of the large-diameter soil nail 6, the end connection control member 7 and the prefabricated tie beam 8 according to the engineering requirements, and submit it to the factory for production; clean up the slope The sundries on the slope body 9 are leveled and compacted, a water intercepting ditch 10 is set at the top of the slope, a drainage groove is set on the slope surface, and a drainage ditch 11 is set at the bottom of the slope;

[0062] Step 2, spray a layer of 5mm thick concrete surface layer to the leveled slope body 9 to form the initial concrete spray layer 5;

[0063] Step 3, accurately locate the positions of the first layer and the second layer of soil nails 6 according to the design requirements and add marks at these positions...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com