Lifting mechanism and civil engineering steel truss erecting device

A lifting mechanism and civil engineering technology, applied in the direction of lifting devices, lifting frames, etc., can solve the problems of inability to secure steel trusses, troubles, heavy lifting devices, etc., and achieve the effect of convenient erection process and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

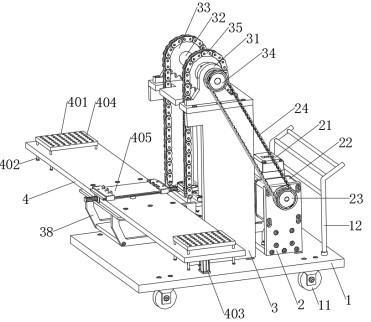

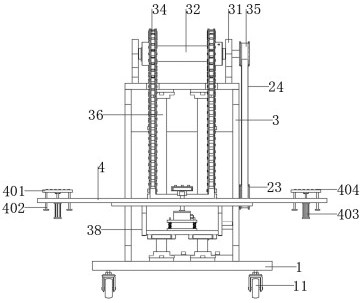

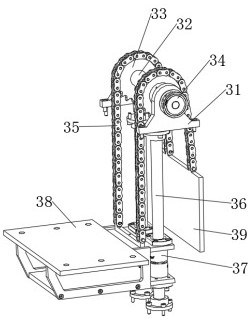

[0028] Example: see Figure 1-5 , a lifting mechanism, comprising a mounting bracket 2 and a lifting platform 3 arranged in front of the mounting bracket 2, both sides of the interior of the lifting platform 3 are vertically provided with columns 36, and the front of the lifting platform 3 is provided with a top surface Keep the horizontal bearing frame 38, the two ends of the column 36 are respectively fixedly connected to the inner top surface and the inner bottom surface of the lifting platform 3, the column 36 is provided with sliding sleeves 37, and the sliding sleeves 37 are fixedly connected to the bearing frame 38; The sliding sleeve 37 is a short tubular structure, which is slidably sleeved on the column 36, so that the bearing frame 38 can be lifted up and down along the column 36 to lift the steel truss.

[0029] Both sides of the top surface of the lifting platform 3 are provided with fixed mounts 31, and above the top surface of the lifting platform 3, a rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com