Universal die cutting machining process for solving hole waste discharge

A processing technology, die-cutting technology, applied in the direction of metal processing, etc., can solve the problems of high production cost, high non-discharge rate of waste film, and incomplete waste discharge, etc., to achieve good waste discharge effect, good versatility, and high-quality products good yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

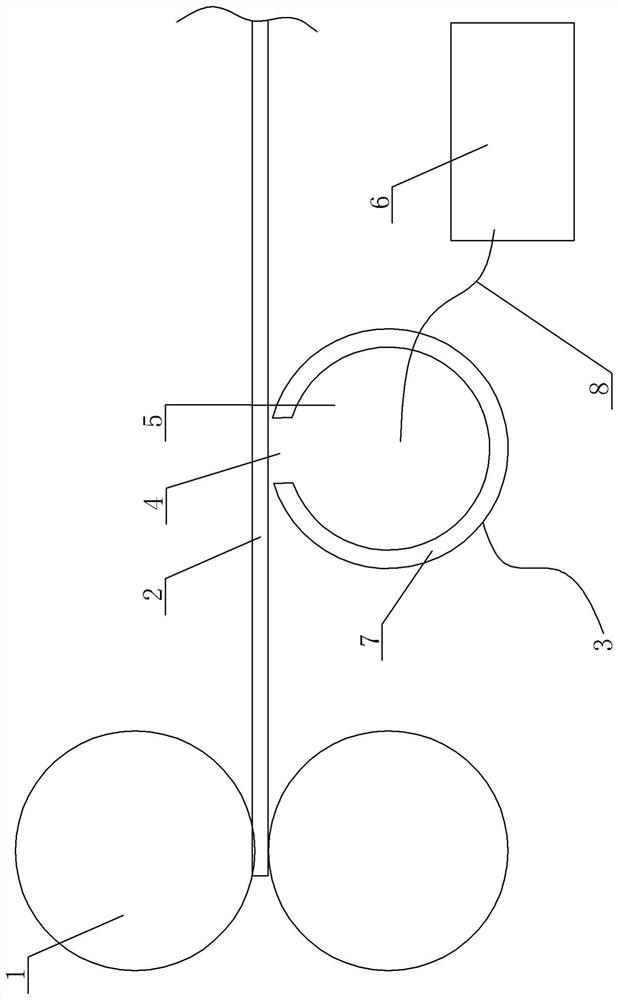

[0013] A general die-cutting process for solving hole waste, see figure 1 : It includes a roller knife 1 for die-cutting, a conveying track 2 for conveying products, an adsorption device 3 is arranged behind the conveying track 2 corresponding to the product conveying of the roller knife 1, and the die-cutting of the product toward the adsorption device 3 The removal surface is provided with a waste suction tank 4, and the inlet of the inner cavity 5 of the adsorption device 3 is connected to the waste suction tank 4, and the adsorption device 3 also includes a suction device 6, which is connected to the inner cavity 5, and the suction device 6 sucks the product The waste on the surface is adsorbed and then discharged.

[0014] The waste suction device 3 includes a fixed drum 7, a suction pipe 8, and a suction device 6. The die-cutting removal surface of the fixed drum 7 facing the product is provided with a waste suction groove 4, and the length surface of the waste suction g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com