Cast iron base structure of box type motor unilateral wind path and box type motor

A cast iron base and box-type technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., to achieve the effects of shortening the production cycle, stable and reliable product performance, and reducing overall costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

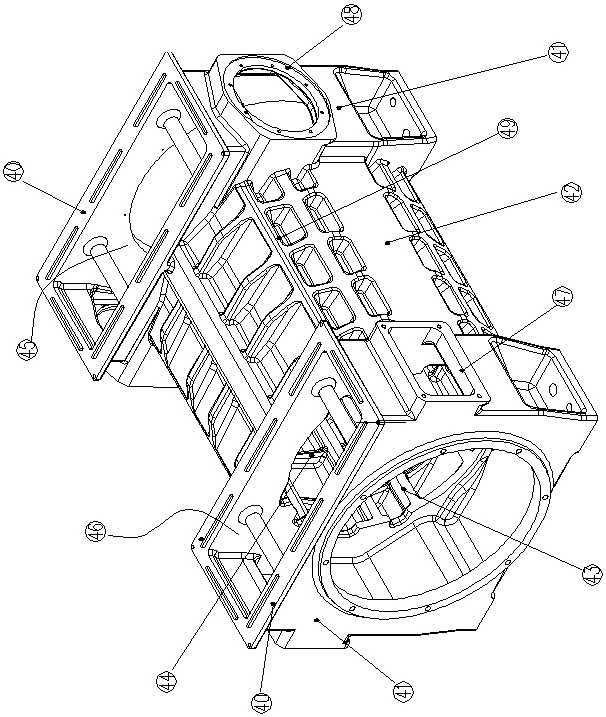

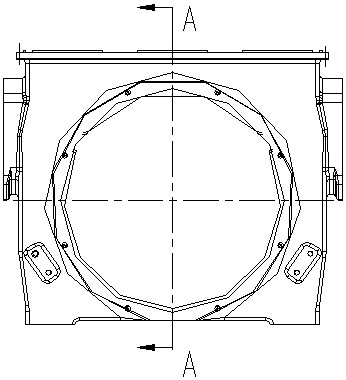

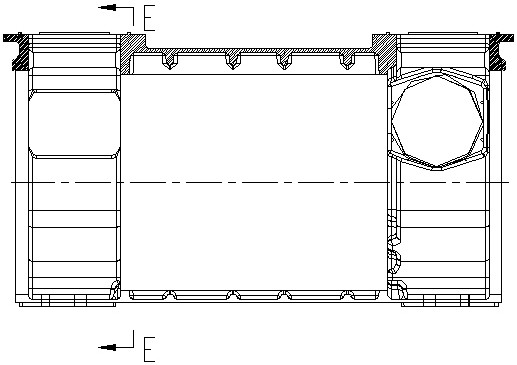

[0041] Such as Figure 1 to Figure 5 As shown, the present embodiment discloses a cast iron frame structure of a box-type motor with a single-side air path, including a cast iron frame 4 integrally cast from gray cast iron H250. The cast iron machine base 4 is integrally formed by two side square boxes 41 and a middle cylinder 42 .

[0042] The middle circle 42 includes a core tube, and the upper circumference of the core tube is provided with convex axial inner ribs 43, and the axial air passage of the machine base is formed between the axial inner ribs 43; the inner convex axial ribs 43 not only has an interference fit with the outer diameter of the stator iron core, supports and installs the stator iron core, but also plays a role in strengthening the overall rigidity and strength of the machine base. A radially inner reinforcing rib 44 is also arranged inside the mandrel, and the inner convex height of the radially inner reinforcing rib 44 is lower than that of the axiall...

Embodiment 2

[0051] Such as Figure 6 to Figure 7 As shown, this embodiment discloses a box-type motor, which includes the cast iron base structure of the single-side air passage of the box-type motor described in Embodiment 1, and also includes a stator installed in the cast iron base 4 and a matching rotor.

[0052] The stator is mainly composed of a stator core 8 and a stator winding 7 . The stator core 8 is a clip-type stator core, which is composed of a stator punch, a stator ventilation slot plate, a stator pressure ring and a clip. It is fixed into a whole by the clips evenly distributed around the circumference, so it is called a clip stator core. The structure of the clip-type stator core is the prior art, and the specific structure will not be described in detail.

[0053] The stator core 8 is also provided with a stator temperature measuring element 9 . The stator core 8 is also provided with wire clamps 10, which are evenly distributed on the circumference and welded on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com