High-temperature pressure sensor and preparation method thereof

A technology of pressure sensor and sensor head, which is applied in the direction of measuring fluid pressure, measuring fluid pressure through electromagnetic components, and fluid pressure measurement using capacitance changes. It can solve problems such as poor dynamic performance and large temperature drift, and achieve high-precision dynamic measurement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

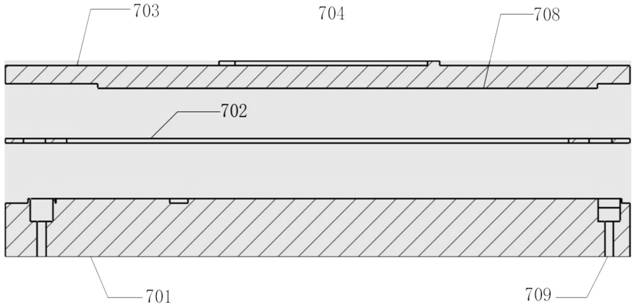

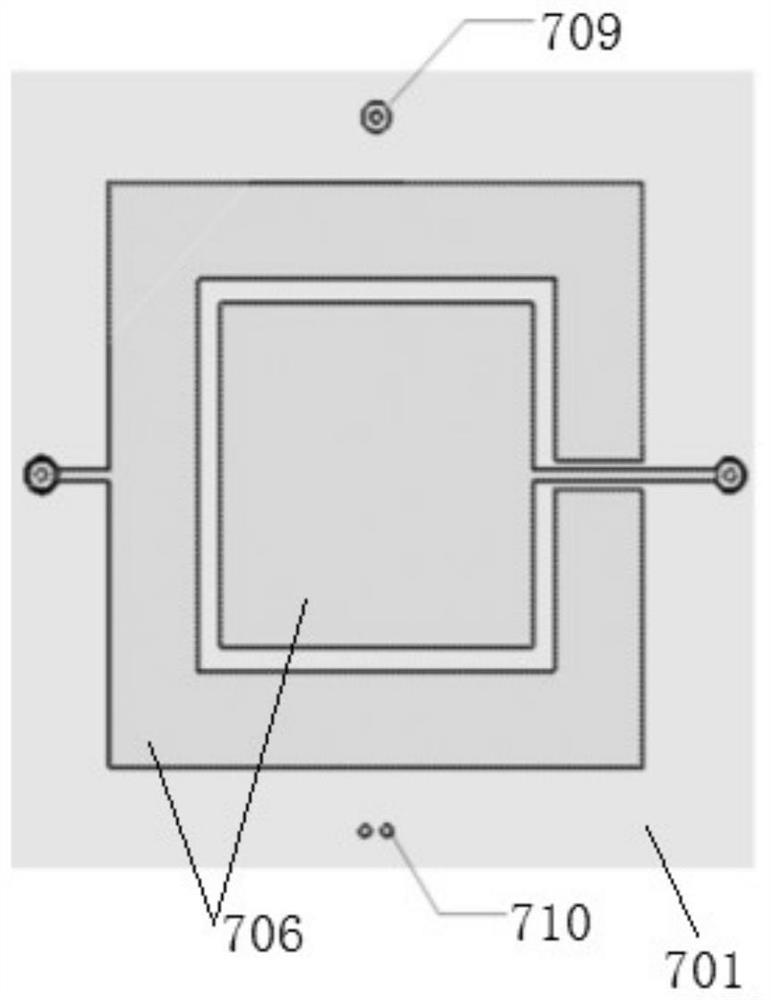

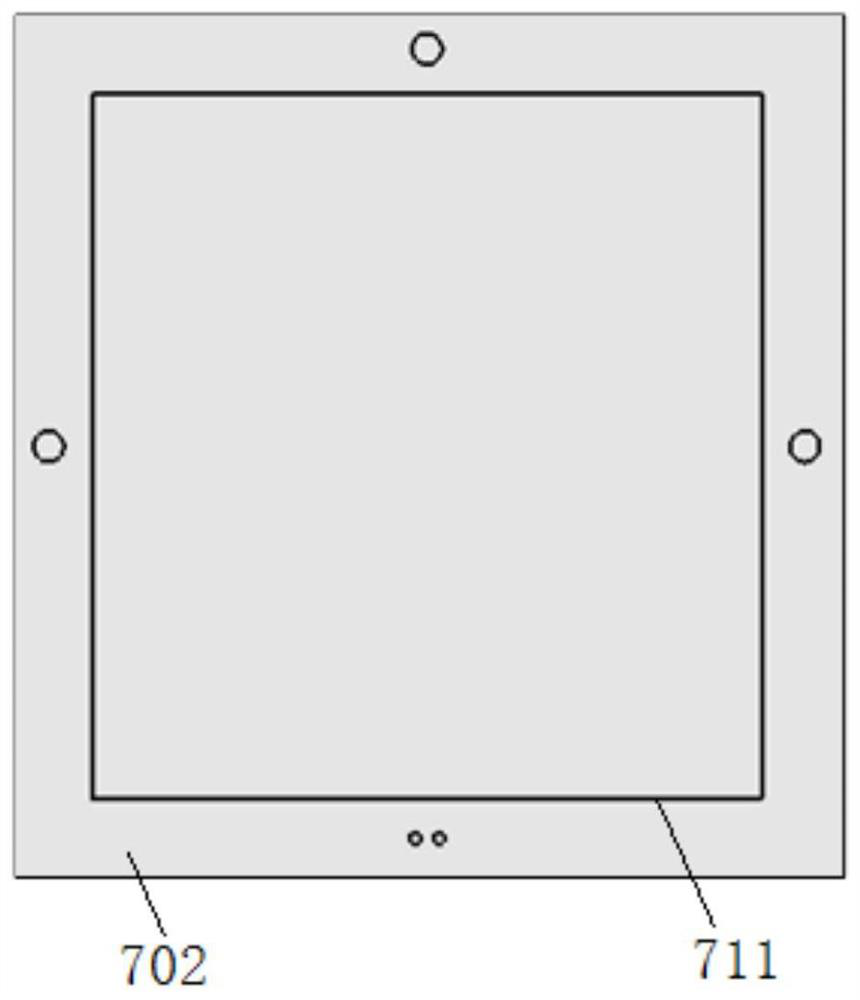

[0063] A specific embodiment of the present invention will be described in detail below in conjunction with accompanying drawings 1-6, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

[0064] The present invention provides a high-temperature pressure sensor, which includes a sensor head and a conversion circuit board connected to each other, and the sensor head includes:

[0065] The packaging shell 1 is provided with a cavity 2 inside, one end of the cavity 2 is provided with an airflow channel 13, and the other end is provided with a connecting part 14;

[0066] The sensitive microstructure 7 is arranged in the cavity 2;

[0067] The front snap ring 6 is arranged at the front end of the cavity 2 to limit the front end of the sensitive microstructure 7;

[0068] The rear snap ring 8 is arranged at the rear end of the cavity 2 to limit the rear end of the sensitive microstructure 7;

[0069] The conver...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap