Novel spiral wheel type miniature pipeline detection robot and using method

A robot and screw wheel technology, applied in special pipes, pipe components, mechanical equipment, etc., can solve the problems of pipe loss, difficulty in detecting pipes, and inaccessibility of instruments, and achieve the effect of good centering effect and accurate data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

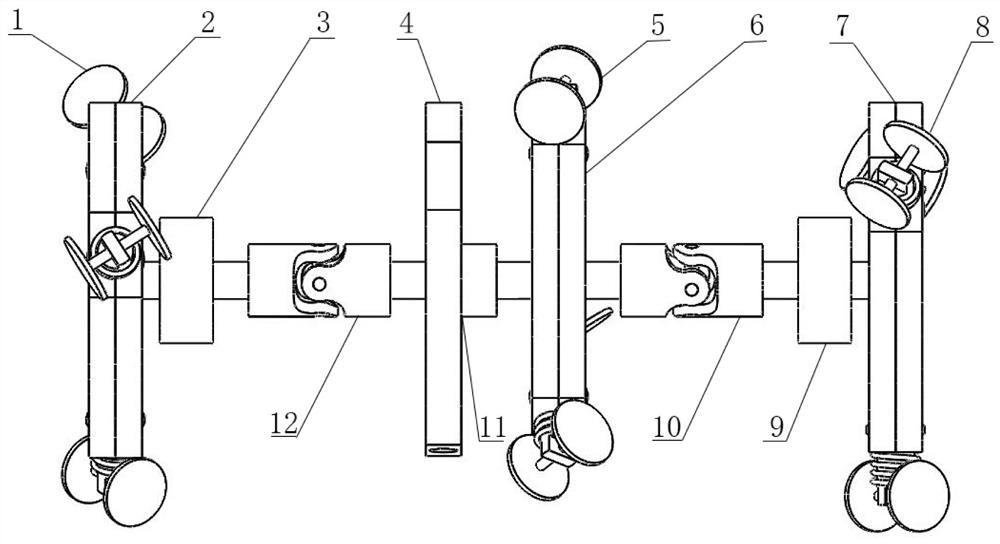

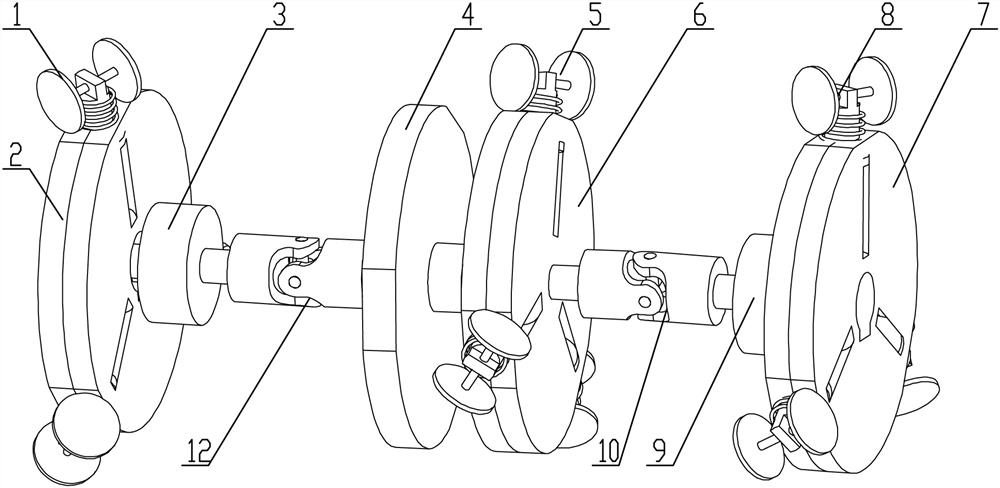

[0029] see Figure 1-3 , a new type of helical wheel type micro-pipe detection robot, which includes a robot main body, the robot main body adopts a segmented structure, including a front axle drive, a support part, a detection part and a rear axle drive; The second universal joint coupling 12 is hingedly connected to the detection part, the detection part is fixedly connected to the supporting part, and the supporting part is hingedly connected to the rear axle through the first universal joint coupling 10 . By using the above-mentioned detection robot, the present invention not only has a simple and reliable structure and is convenient to use, but also can complete the exploration work inside the pipeline and detect the problems existing in the pipeline in time. In the specific use process, the entire robot can be driven to walk smoothly inside the pipeline by the front axle drive and the rear axle drive. The first universal joint coupling 10 and the second universal joint c...

Embodiment 2

[0040] The method of using the novel helical wheel type micro-pipe detection robot to detect the interior of the pipeline includes the following steps:

[0041] Step 1: Start the first motor 3 and the second motor 9 of the front axle drive and the rear axle drive, the drive link will transmit the torque to the front axle rotating wheel 2 and the rear axle rotating wheel 7, through the front axle rotating wheel 2 and The rear axle rotating wheel 7 synchronously drives the front axle spring wheel 1 and the rear axle spring wheel 8 on its outer circumference to contact the inner wall of the pipeline, so that the robot can overcome the obstacles in the pipeline, and the positive pressure can also be replenished in time. Backwards, you only need to change the direction of the current applied to the motor, so that the robot can move in the opposite direction;

[0042] Step 2: When the helical-wheeled micro-pipe detection robot encounters the situation that the debris on the inner wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com