An embroidery machine laser control device and method

An embroidery machine and laser technology, which is applied to embroidery machines, embroidery machine mechanisms, automatic control embroidery machines, etc., can solve the problems of low efficiency of model change, inability to save parameters, inconvenient operation, etc., and achieve simple setting, upgrade and change Efficiency and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

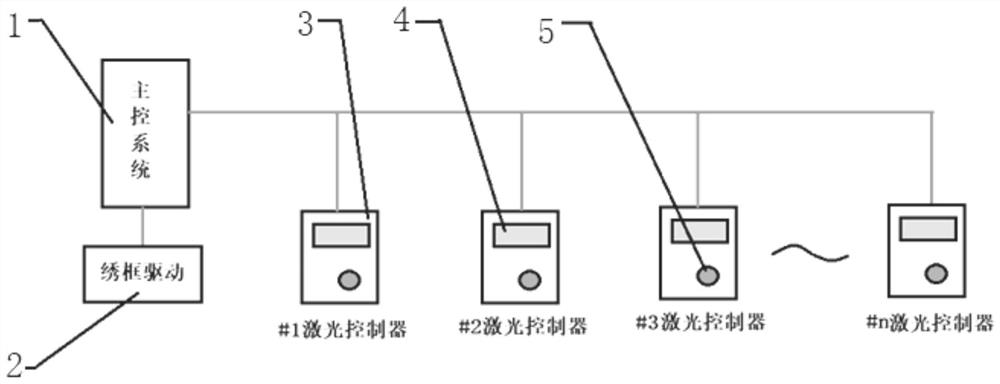

[0031] Such as figure 1 As shown, an embroidery machine laser control device includes an embroidery machine main control system 1, an embroidery frame drive system 2 communicating with the embroidery machine main control system, and a communication connection with the embroidery machine main control system 1 and corresponding to each machine head. A laser controller 3 provided separately for the laser heads. The laser controller 3 is provided with a power display screen 4 and a power fine-tuning knob 5 .

[0032] Wherein, the main control system 1 of the embroidery machine is provided with an embroidery parameter storage module and a pattern parameter calling module, and the embroidery parameter storage module stores embroidery frame speed parameters and laser power parameters of each laser controller corresponding to each pattern, so The above-mentioned pattern parameter calling module writes the corresponding embroidery frame speed parameters into the embroidery frame drive...

Embodiment 2

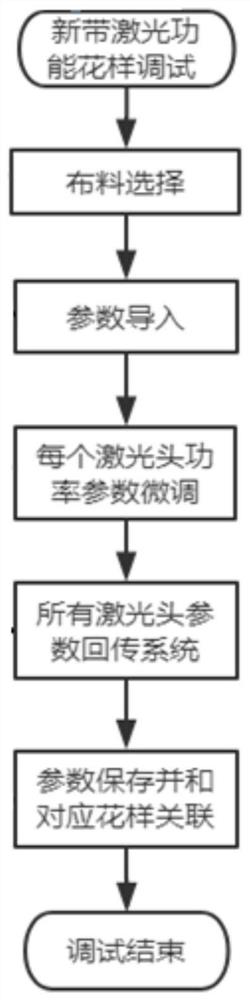

[0036] A laser control method for an embroidery machine, comprising the following steps in sequence:

[0037] Embroidery parameter storage: store the embroidery frame speed parameters corresponding to each pattern and the laser power parameters of each laser controller in the embroidery parameter storage module of the main control system of the embroidery machine;

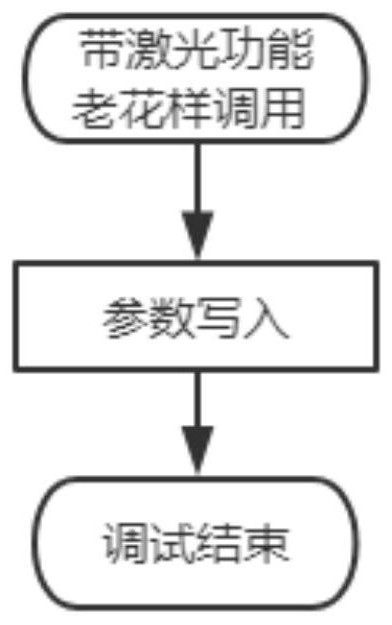

[0038] Pattern parameter call: After any pattern is called, write the corresponding frame speed parameters into the frame drive system, and write the laser power parameters of each laser controller into the corresponding laser controller according to the address;

[0039] Laser embroidery: During the laser embroidery process, the embroidery frame drive system drives the embroidery frame according to the written embroidery frame speed parameters, and each laser controller controls the laser head according to the corresponding laser power parameters.

[0040] The frame speed parameters corresponding to each pattern a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com