Warning adhesive tape and preparation method thereof

A tape and glue technology, applied in the direction of adhesives, other rubber adhesives, natural rubber adhesives, etc., can solve the problems of insufficient fusion of PVC substrates, discoloration, discoloration, and affecting the appearance of the adhesive, so as to avoid ultraviolet rays Effects of aging damage, prevention of fading or discoloration, enhancement of fusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to understand the technical solution adopted by the present invention more clearly, preferred embodiments of the present invention will be described below. It should be understood that the embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

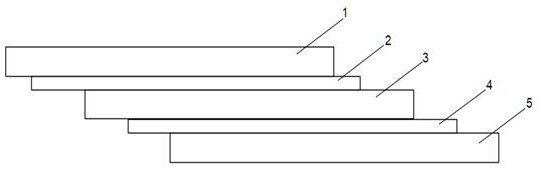

[0032] A warning tape, which includes a transparent PVC film 1, a printing layer 2, a PVC base material 3, a bridging agent layer 4 and a glue layer 5 stacked from top to bottom;

[0033] Wherein, after adding the printing layer 2 to the 3 layers of the PVC base material, the transparent PVC film 1 is hot-pressed and pasted.

[0034] Protect the PVC base material 3 and the printing layer 2 by setting the transparent PVC film 1 on the printing layer 2, and heat the transparent PVC film 1 after adding the printing layer 2 through the PVC base material 3 layers, thereby protecting the printing layer 2, In addition, 3 layers of PVC base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com