High-efficiency feed permanent magnet cylinder

A technology of permanent magnet cylinder and permanent magnet drum, which is applied in the fields of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of being too late to deal with, destroying mechanical equipment, and that the permanent magnet cylinder cannot meet the removal of iron-containing impurities in materials, etc. Achieving the effect of high work efficiency, good reliability and good safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

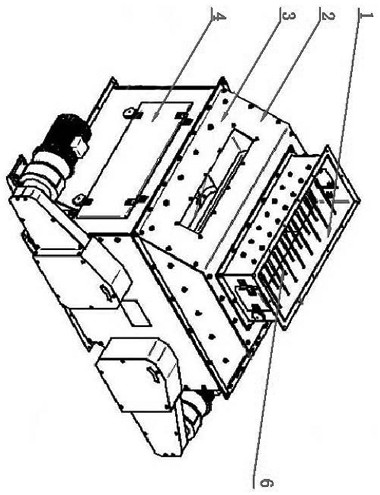

[0014] Such as figure 1 As shown, the purpose of the present invention is achieved in this way: a permanent magnet cylinder for high-efficiency feed, comprising a permanent magnet cylinder 3, is characterized in that, the permanent magnet cylinder 3 is arranged in a rectangular shape, and the permanent magnet cylinder 3 above A cover 2 is provided, and a feed inlet 1 is arranged on the top of the cover 2. The feed inlet 1 is arranged in a long strip shape, and a buffer mechanism 5 is arranged in the feed inlet 1. The permanent magnet cylinder 3 A left permanent magnet cylinder and a right permanent magnet cylinder are respectively arranged on both sides, there is a gap between the left permanent magnet cylinder and the right permanent magnet cylinder, and the left permanent magnet cylinder and the right permanent magnet cylinder are respectively provided with driving devices, The driving device is arranged on both sides of the permanent magnet cylinder 3; the left and right si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com