In-situ detection device for compressive strength of sintered common brick by clamping-twisting method

A technology of compressive strength and in-situ detection, which is applied in the direction of measuring device, strength characteristics, and the strength of materials tested by applying a stable torsion force. Enhance the effect of promotion and use value, convenient processing and assembly, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with specific examples, but the present invention is not limited to these specific implementations. Those skilled in the art will realize that the present invention covers all alternatives, modifications and equivalents as may be included within the scope of the claims.

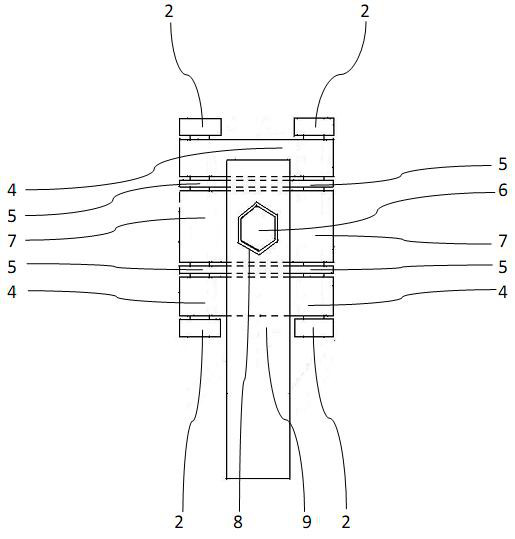

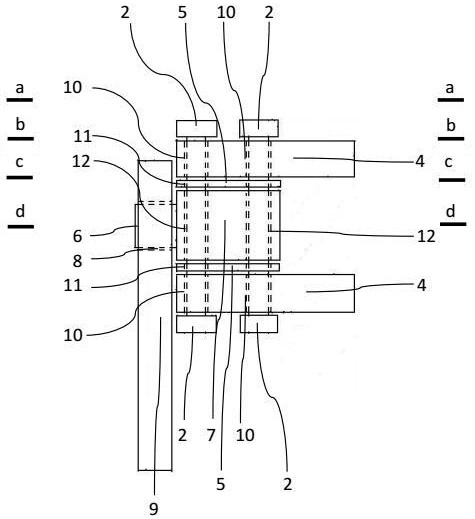

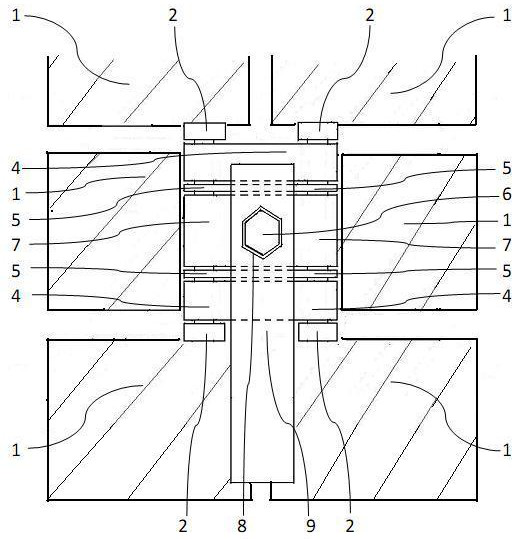

[0024] refer to Figure 1-9 , an in-situ testing device for the compressive strength of sintered common bricks by clamping and torsion method, comprising two metal splints 4 symmetrically arranged on the sides of a cuboid sample 3 in a sintered common brick 1; The metal plug 7 and the thickness adjusting gasket 5 are fixedly connected; the metal splint 4, the metal plug 7 and the thickness adjusting gasket 5 cover the cuboid sample 3 under it; the metal plug 7 passes through the metal hexagon Head 6 is connected with digital display torque wrench 9. In the present invention, the cuboid sample 3 in the sintered common brick 1 is clam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com