Modular assembling method for prefabricated spherical fragment of ammunition warhead

An assembly method and warhead technology, applied to ammunition, weapon accessories, offensive equipment, etc., can solve problems such as the difficulty of realizing special-shaped warheads, achieve easy design requirements, meet design requirements, and reduce labor intensity and work difficulty of workers Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

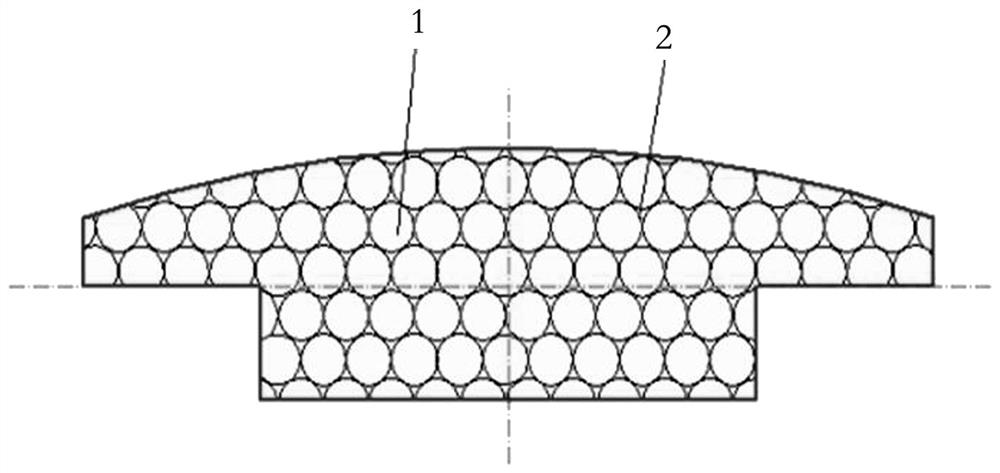

[0026] This fragment module is a schematic diagram of the modular structure of a large warhead cavity head fragment ( figure 1 ). In order to make full use of the inner cavity space of the warhead head and ensure the quality and center of mass of the warhead, the fragmentation module of this structure is designed. The specific process method is as follows:

[0027] First, determine the shape and size of the module according to the technical parameters of the warhead, design and process the mold. Clean the fragments with gasoline and alcohol, weigh the spherical fragments and put them into the mold according to the requirements of the drawing, vibrate or shake to make them densely arranged, slowly inject the vacuumed adhesive into the mold, let the adhesive fill every gap in the fragments, and then seal the mold, according to the process Heating and curing at the required temperature. After curing, disassemble the mold, clean and weigh the module, and apply adhesive evenly o...

Embodiment 2

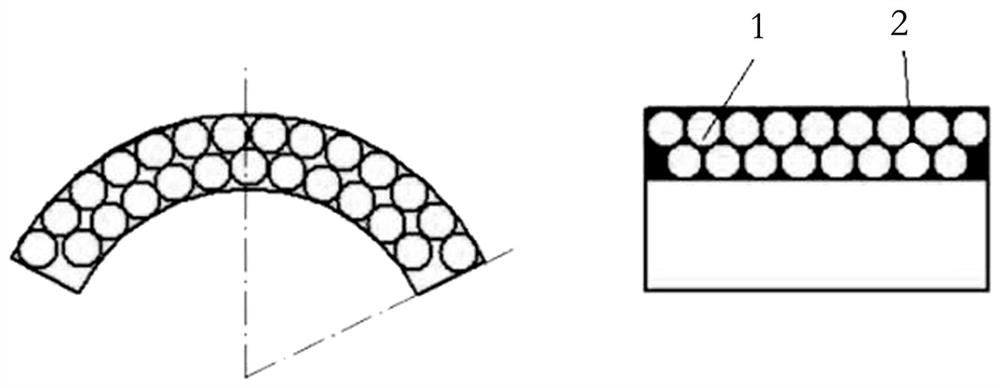

[0029] This fragment module is a schematic diagram of the modular structure of the cylindrical part of a small warhead ( figure 2 ), if the size of the mouth of the warhead is smaller than the size of the inner cavity, the overall design fragment module cannot be assembled. After the fragment module is divided into three equal parts (divided along the circumferential direction), they are respectively pasted on the inner wall of the warhead shell. The specific process method is:

[0030] According to the design requirements, the fragments are initially divided into three equal parts. After the equal parts, the size of each fragment is just smaller than the size of the mouth of the warhead, which can realize smooth assembly. First, design and manufacture the mold according to the size and shape of each piece, weigh the spherical fragments into the mold, vibrate or shake to make the distribution dense; place the mold vertically on the platform, slowly inject the vacuumed adhesiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com