Single-core mask line manufacturing process

A manufacturing process and mask technology, applied in the field of single-core mask line manufacturing process, can solve the problems of low production speed and limited production efficiency of mask nose clip line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1, single-core mouth mask line manufacturing process, comprises the following steps:

[0025] A. Prepare materials, prepare metal core wire and insulating material, the metal core wire is a steel wire with a diameter less than 0.5mm, and the insulating material is composed of polyethylene with a mass fraction of 80% and polypropylene with 20%;

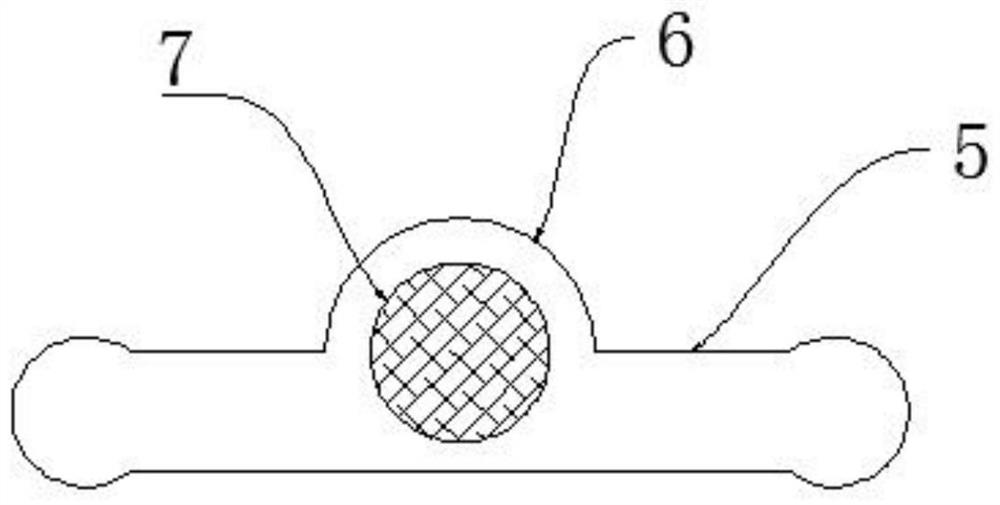

[0026] B, mold opening, ready to extrude mold 1, such as figure 1 As shown, the extrusion die 1 is provided with a discharge port, the discharge port includes a rectangular hole 2, the left and right ends of the rectangular hole 2 are connected with a circular hole 3, and the diameters of the two circular holes 3 are larger than the rectangular hole 2 The distance between the upper and lower walls, the two circular holes 3 are processed to the same diameter, the centers of the two circular holes 3 are all positioned on the vertical axis of symmetry of the rectangular hole 2, and each circular hole 3 is aligned with th...

Embodiment 2

[0029] Embodiment 2. In this embodiment, the insulating material is composed of polyethylene with a mass fraction of 70% and polypropylene with a mass fraction of 30%, and the extrusion speed is 160 m / min.

Embodiment 3

[0030] Embodiment 3. In this embodiment, the insulating material is composed of polyethylene with a mass fraction of 90% and polypropylene with a mass fraction of 10%, and the extrusion speed is 120 m / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com