Circulating floating foam remover for hotpot restaurant

A frother and hot pot technology, applied in the field of kitchen utensils, can solve the problems of labor, time-consuming, labor-intensive, low-efficiency, affecting the sense of experience, etc., and achieve the effects of easy promotion, low cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

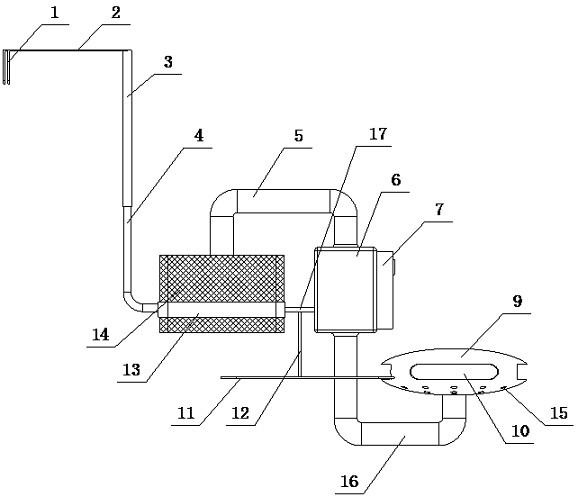

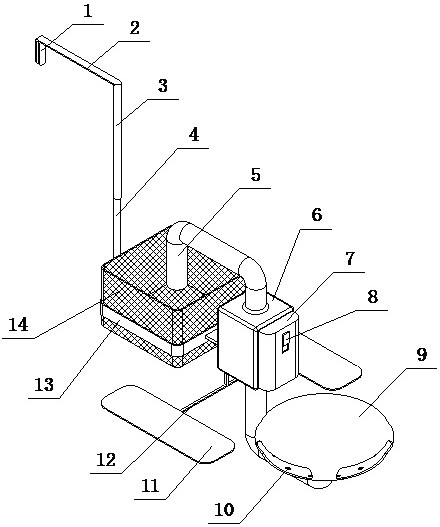

[0017] A circulating defoamer for hot pot restaurants of the present invention is realized in the following way: a circulating defoamer for hot pot restaurants of the present invention is composed of a collecting device and a fixing device, and the collecting device is composed of a drain pipe (5), a water pump (6) , power supply box (7), switch (8), collection head (9), water inlet hole (10), floating plate (11), connecting rod (12), fixed frame (13), collection box (14), communication Hole (15), pumping pipe (16) and connecting plate (17), the fixing frame (13) is placed on the collection box (14), the collection box (14) is a net box structure, the connecting plate (17 ) is placed on one side of the fixed frame (13), the water pump (6) is placed on the other end of the connecting plate (17), the connecting rod (12) is placed on the bottom of the connecting plate (17), and the connecting rod ( 12) It consists of a horizontal bar and a vertical bar. One end of the vertical ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com