Three-state actuated demoulding type suspended filler for sewage treatment

A technology for sewage treatment and suspended filler, which is applied in biological water/sewage treatment, water/sludge/sewage treatment, sustainable biological treatment, etc. and other problems to achieve the effect of reducing clogging, improving fluidity and full contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

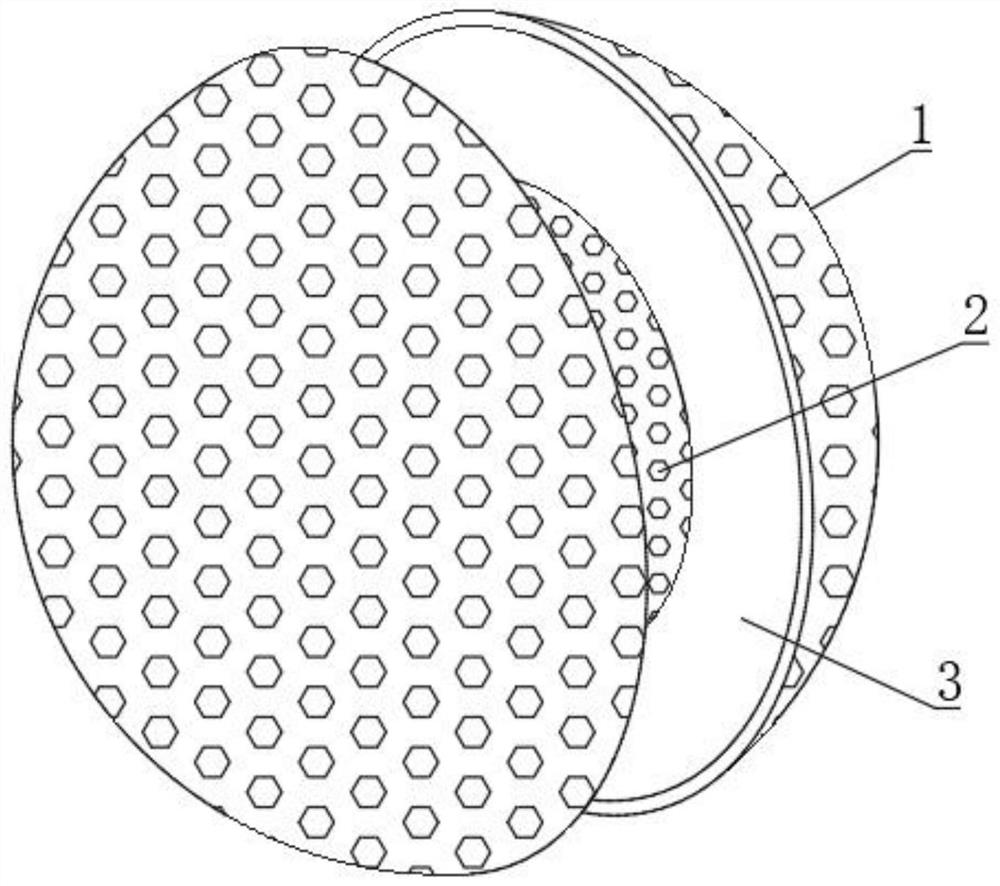

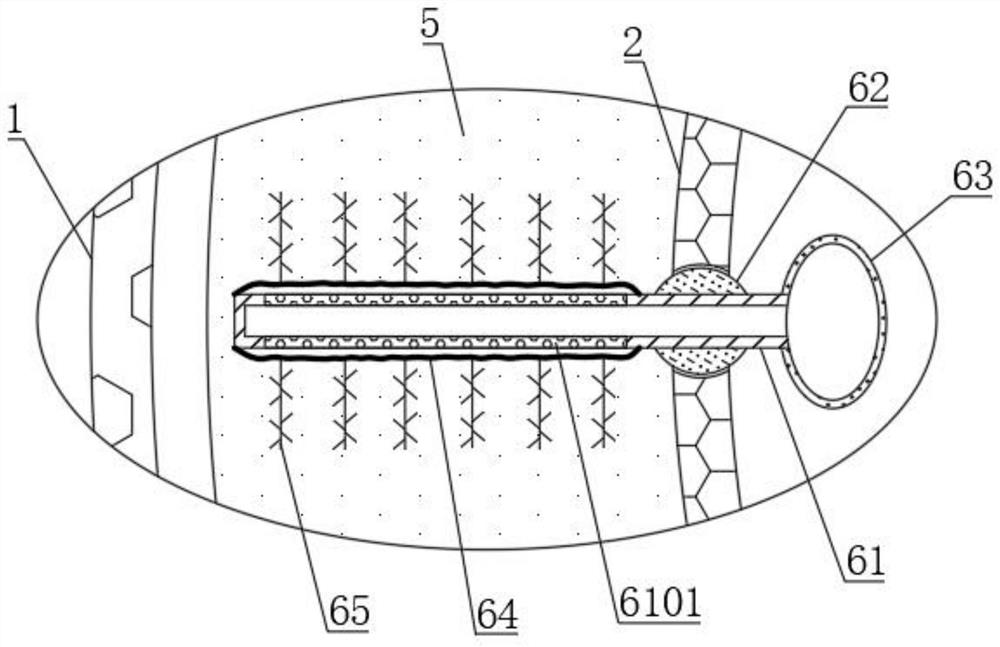

[0040] see figure 1 and figure 2 , a kind of three-state induced off-mode suspension filler for sewage treatment, comprising an outer reticulated shell 1, an inner reticulated shell 2 is arranged on the inner side of the outer reticulated shell 1, and a pair of mutually parallel reticulated shells are fixedly connected between the outer reticulated shell 1 and the inner reticulated shell 2 And with respect to the chain piece 3 symmetrical to the center of the outer reticulated shell 1, an annular water channel is opened on the outer reticulated shell 1, and the annular water channel is located between a pair of connected plates 3, and a three-state mixing ball group 4 is placed on the inner side of the inner reticulated shell 2, The three-state mixing ball group 4 is formed by mixing floating balls, suspension balls and sinking balls at a ratio of 1:1:1. The outer reticulated shell 1 and the inner reticulated shell 2 are filled with a film-attached silk layer 5, and the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com