Full-automatic cleaning and detecting production line for lithium battery electrolyte packaging barrel

A fully automatic technology for cleaning and packaging barrels. It is used in measuring devices, cleaning hollow objects, cleaning methods and utensils. It can solve problems such as low efficiency, personal danger to operators, and residual electrolyte.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] Hereinafter, exemplary embodiments of the present invention will be described in detail with reference to the accompanying drawings. The following embodiments are provided by way of illustration in order to fully convey the spirit of the present invention to those skilled in the art to which the present invention pertains. Therefore, the present invention is not limited to the embodiments disclosed herein.

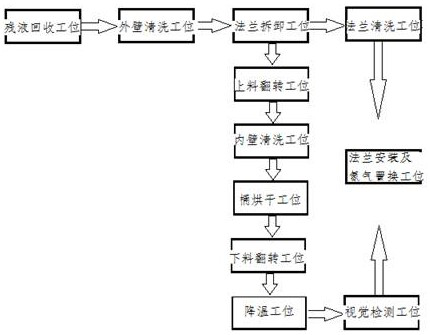

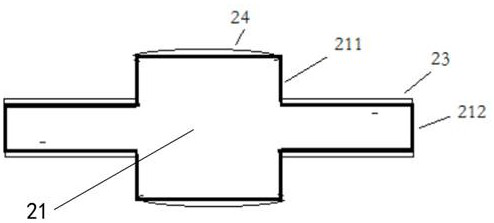

[0062] Such as figure 1 As shown, the inventive lithium battery electrolyte packaging barrel automatic cleaning and testing production line can include residual liquid recovery station, outer wall cleaning station, flange disassembly station, flange cleaning station, feeding turning station, inner wall cleaning station station, barrel drying station, blanking and turning station, cooling station, visual inspection station, flange installation and nitrogen replacement station.

[0063] According to the present invention, an RFID tag is set on the electrolyte packag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| luminance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com