Coupling agent coating equipment for manufacturing insulator for power transmission

A coupling agent and insulator technology, applied in the field of power transmission, can solve the problems of time-consuming and labor-intensive fixing process, inconvenient fixing of insulators, and damage to the health of workers. damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

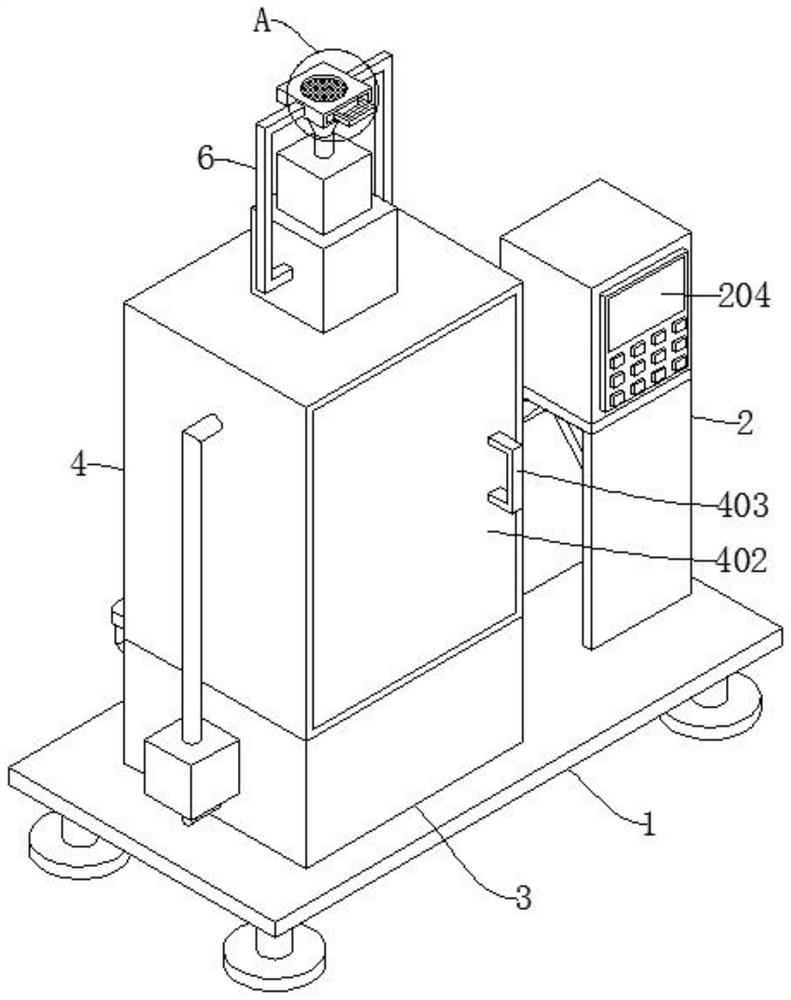

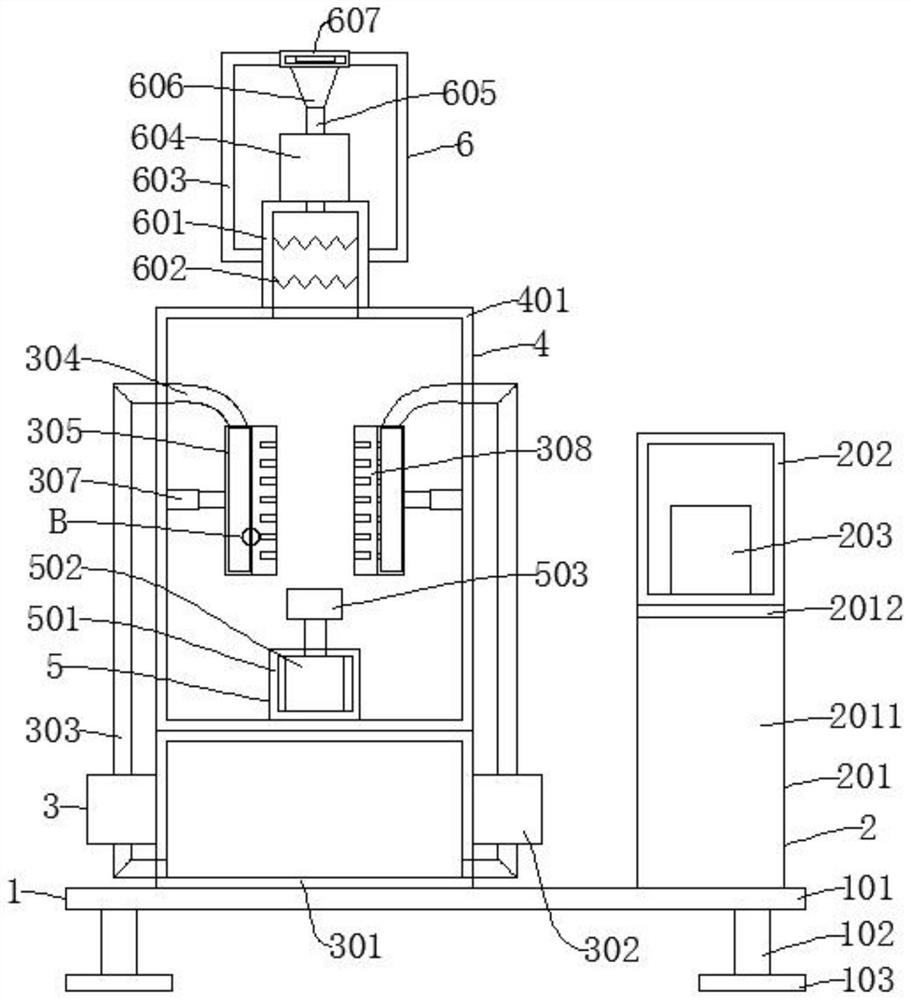

[0046] Such as figure 1 , image 3 , Figure 5 , Figure 7 , Figure 8 , Figure 9 As shown, a coupling agent coating equipment made of insulators for power transmission includes a support mechanism 1, a control mechanism 2 for controlling the operation of the device, a coating mechanism 3, and a closing mechanism 4. A control mechanism 2 is installed above the support mechanism 1 One side of the control mechanism 2 is provided with a coating mechanism 3, and a sealing mechanism 4 is fixed above the coating mechanism 3, and also includes a rotating mechanism 5, a drying mechanism 6, and a purification mechanism 7. The rotating mechanism 5 is installed inside the sealing mechanism 4, and the drying mechanism 6 is installed above the closing mechanism 4, and the purification mechanism 7 is fixed at the rear of the closing mechanism 4;

[0047] The support mechanism 1 includes a support plate 101, a support column 102, and a chassis 103. The support column 102 is installed b...

Embodiment 2

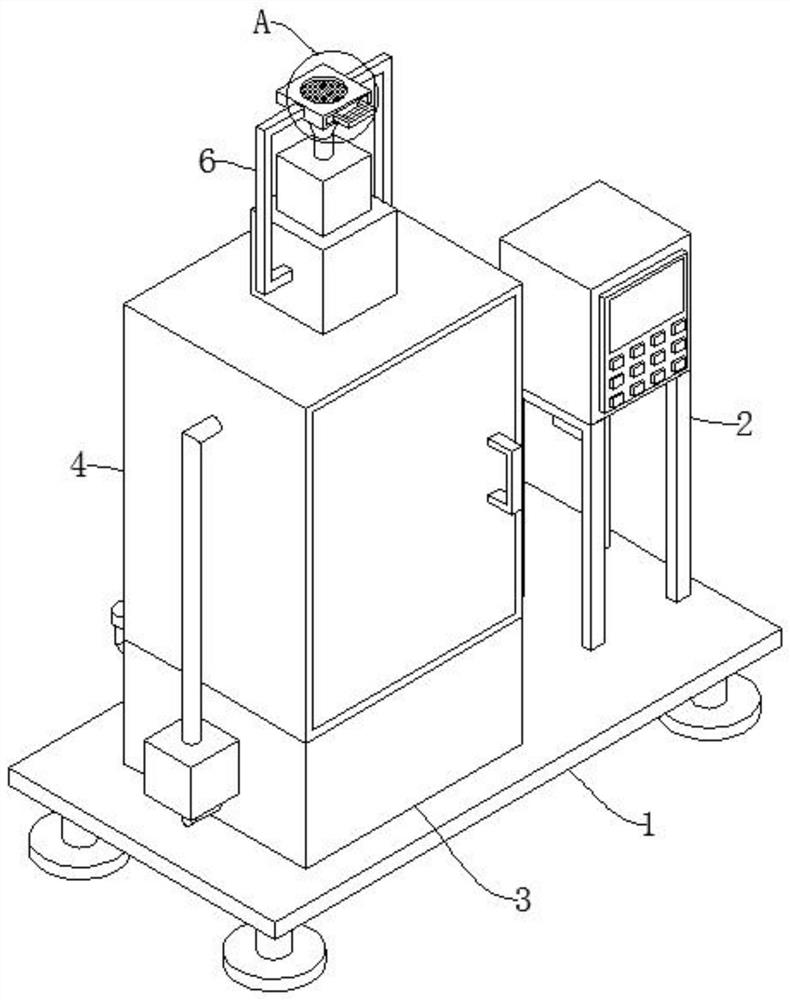

[0057] Such as figure 2 , Figure 4 , Figure 6 , Figure 7 , Figure 8 , Figure 9 As shown, the difference between Embodiment 2 and Embodiment 1 is that the vertical plate 2011, the horizontal plate 2012, and the inclined plate 2013 are replaced by the support frame 2014 and the first fixed frame 2015. During the operation of the device, the support frame 2014 and the first fixed frame A fixing frame 2015 works together to support and fix the control box 202 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com