A kind of high-sensitivity biosensor and its fabrication method and application

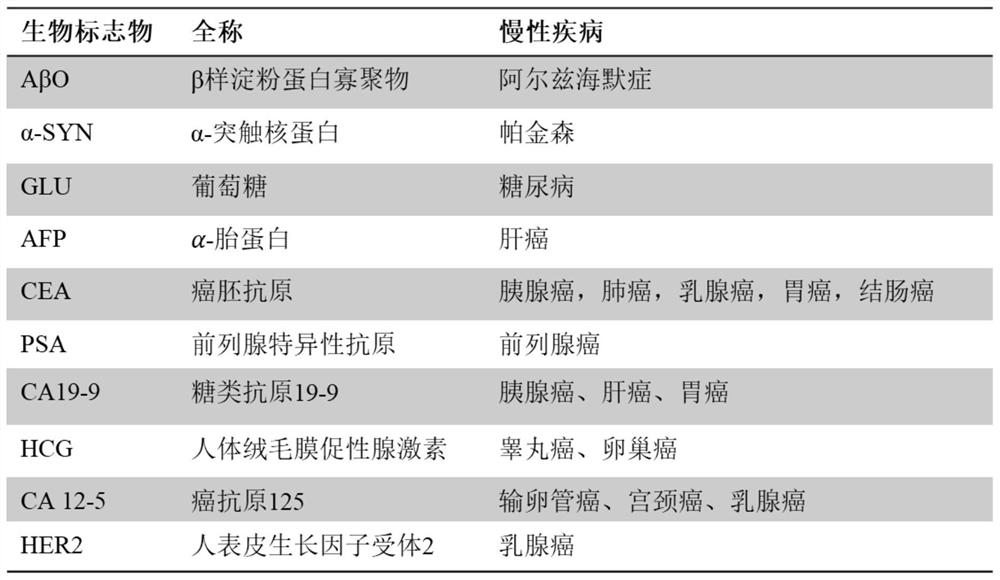

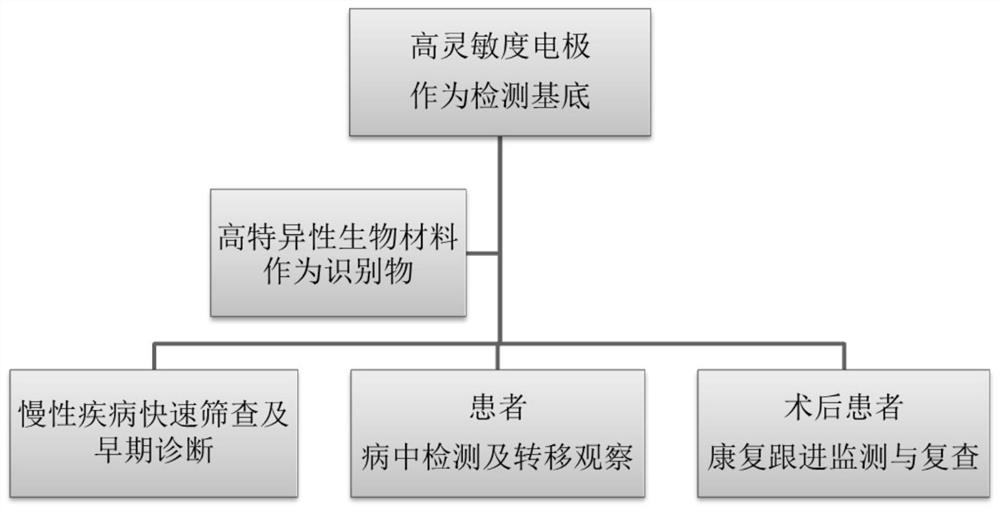

A technology of biosensor and manufacturing method, applied in the field of high-sensitivity biosensor and its manufacture, can solve problems such as narrow detection range, many uncontrollable influencing factors, and complex manufacturing of electrochemical sensors, so as to improve sensitivity, realize trace detection, increase Effect of Surface Active Area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

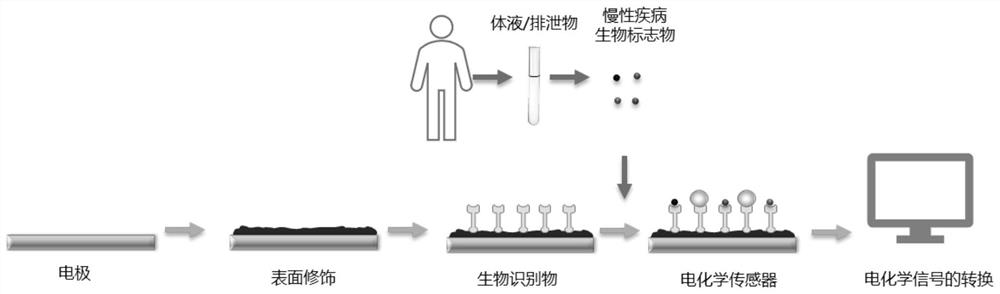

Method used

Image

Examples

Embodiment 1

[0068] The preparation process of highly sensitive biosensors is as follows: Figure 4 As shown, the gold electrodes were physically polished with 0.3 μm and 0.05 μm aluminum oxide in turn, and the surface of the electrodes was cleaned with a large amount of deionized water and ethanol to obtain the mirror surface morphology; the electrodes were immersed in piranha etching solution (30% H 2 O 2 :18M H 2 SO 4 Volume ratio = 1:3) for ten minutes, remove surface impurities by chemical polishing; use cyclic scanning method in 0.5M potassium hydroxide (voltage range: -1.5-0.1V, scan rate 100mv / s scan times 20 times) Electrochemical polishing; electrochemical polishing in 0.5M sulfuric acid using chronoamperometry and cyclic voltammetry (chronoamperometry, 2V, 5s; -0.35V, 10s; cyclic voltammetry, voltage range: -0.3-1.6V, The scan rate was 100 mv / s, and the number of scans was 20), the electrodes were cleaned with water and absolute ethanol, and dried with nitrogen.

[0069] Th...

Embodiment 2

[0075] The preparation process of highly sensitive biosensors is as follows: Figure 7 As shown, the gold electrodes were physically polished with 0.3 μm and 0.05 μm aluminum oxide in turn, and the surface of the electrodes was cleaned with a large amount of deionized water and ethanol to obtain the mirror surface morphology; the electrodes were immersed in piranha etching solution (30% H 2 O 2 :18M H 2 SO 4 Volume ratio = 1:3) for ten minutes, remove surface impurities by chemical polishing; use cyclic scanning method in 0.5M potassium hydroxide (voltage range: -1.5-0.1V, scan rate 100mv / s scan times 20 times) Electrochemical polishing; electrochemical polishing in 0.5M sulfuric acid using chronoamperometry and cyclic voltammetry (chronoamperometry, 2V, 5s; -0.35V, 10s; cyclic voltammetry, voltage range: -0.3-1.6V, The scan rate was 100 mv / s, the number of scans was 20), the electrodes were cleaned with water and absolute ethanol, and dried with nitrogen.

[0076] Take 1...

Embodiment 3

[0083] The preparation process of highly sensitive biosensors is as follows: Figure 11 As shown, the gold electrodes were physically polished with 0.3 μm and 0.05 μm aluminum oxide in turn, and the surface of the electrodes was cleaned with a large amount of deionized water and ethanol to obtain the mirror surface morphology; the electrodes were immersed in piranha etching solution (30% H 2 O 2 :18M H 2 SO 4 Volume ratio = 1:3) for ten minutes, remove surface impurities by chemical polishing; use cyclic scanning method in 0.5M potassium hydroxide (voltage range: -1.5-0.1V, scan rate 100mv / s scan times 20 times) Electrochemical polishing; electrochemical polishing in 0.5M sulfuric acid using chronoamperometry and cyclic voltammetry (chronoamperometry, 2V, 5s; -0.35V, 10s; cyclic voltammetry, voltage range: -0.3-1.6V, The scan rate was 100 mv / s, the number of scans was 20), the electrodes were cleaned with water and absolute ethanol, and dried with nitrogen.

[0084] Take ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com