Adjustable six-component balance calibration device for engine ground test

A ground test and verification device technology, which is applied in the direction of engine test, measurement device, aerodynamic test, etc., can solve the problem that the accuracy and synchronization of multiple component force loading cannot be guaranteed, and achieve the purpose of improving test and test capabilities, Ensure the accuracy and simultaneity of loading, and ensure the effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

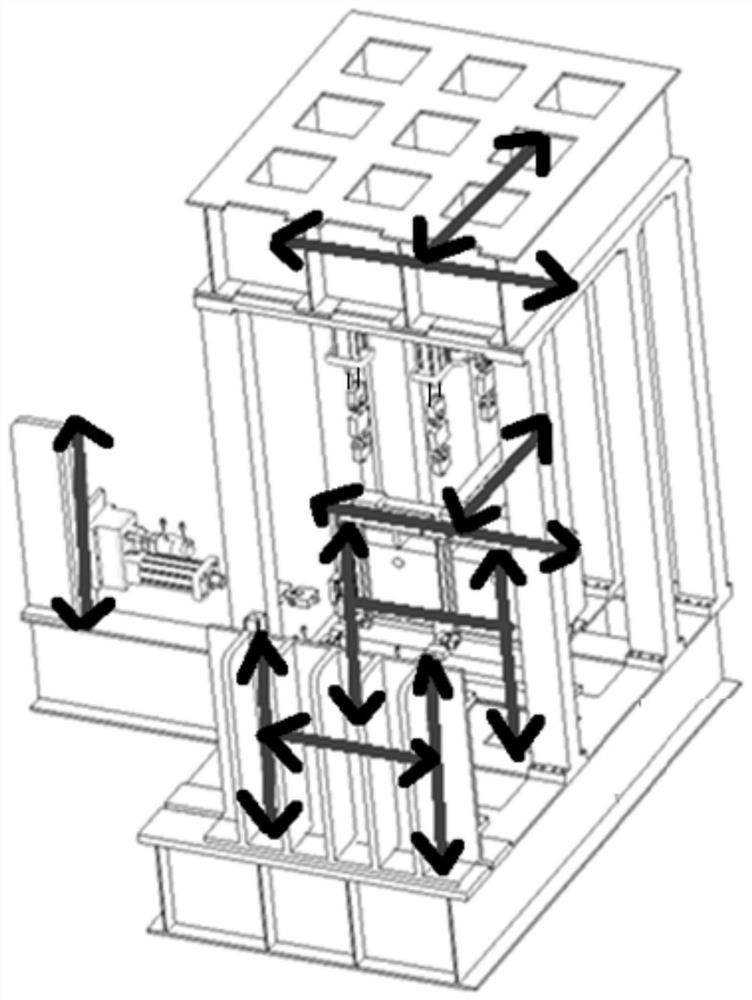

[0045] In order to realize the multi-degree-of-freedom thrust calibration of the six-component balance during the thrust calibration test, the present invention proposes a calibration device that can adjust the position of the force-measuring point. By performing static force loading on 6 positions of the balance, x Apply force and moment to the balance in the , y, and z directions. At the same time, the method of adding slide rails on the force-bearing surface of the balance is adopted to adjust the position of the force point on the balance to complete the force loading with variable positions in the horizontal and vertical directions, and to realize being controlled. Calibration of various forces and moments of measuring balances.

[0046] like figure 1 and figure 2 As shown, an adjustable six-component balance ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com